| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

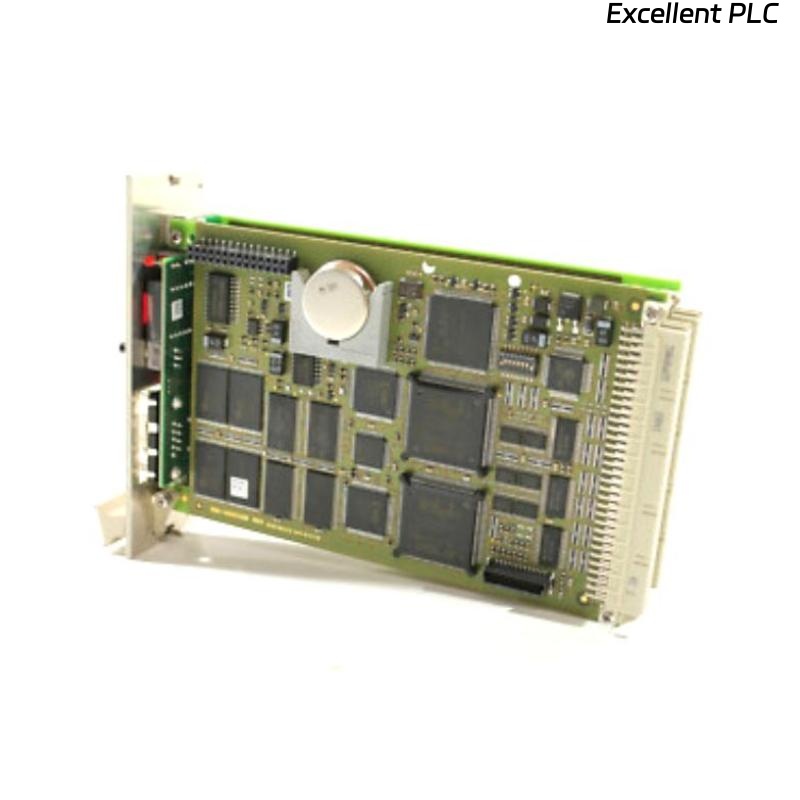

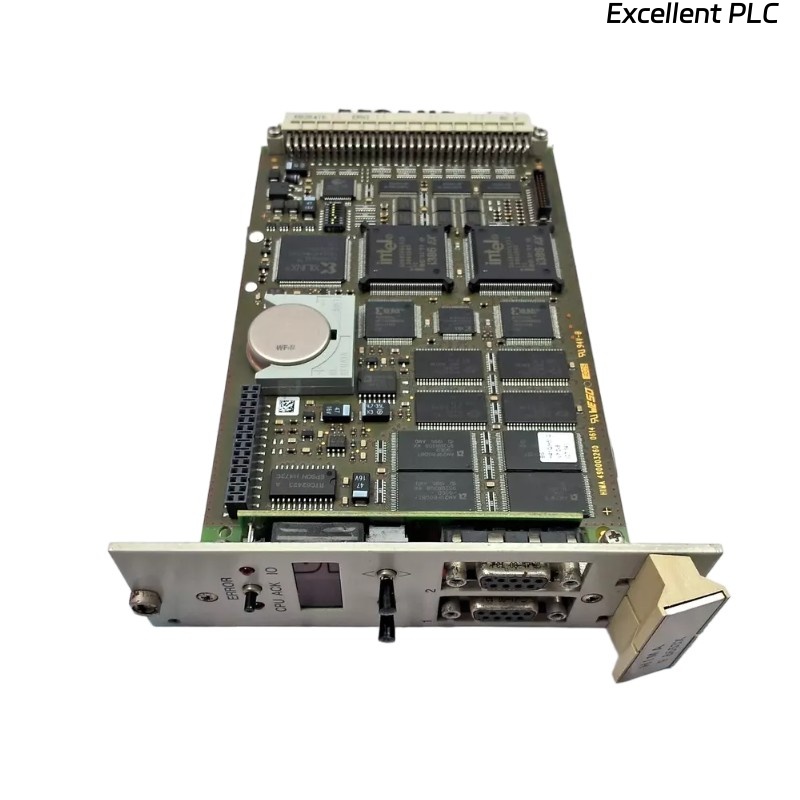

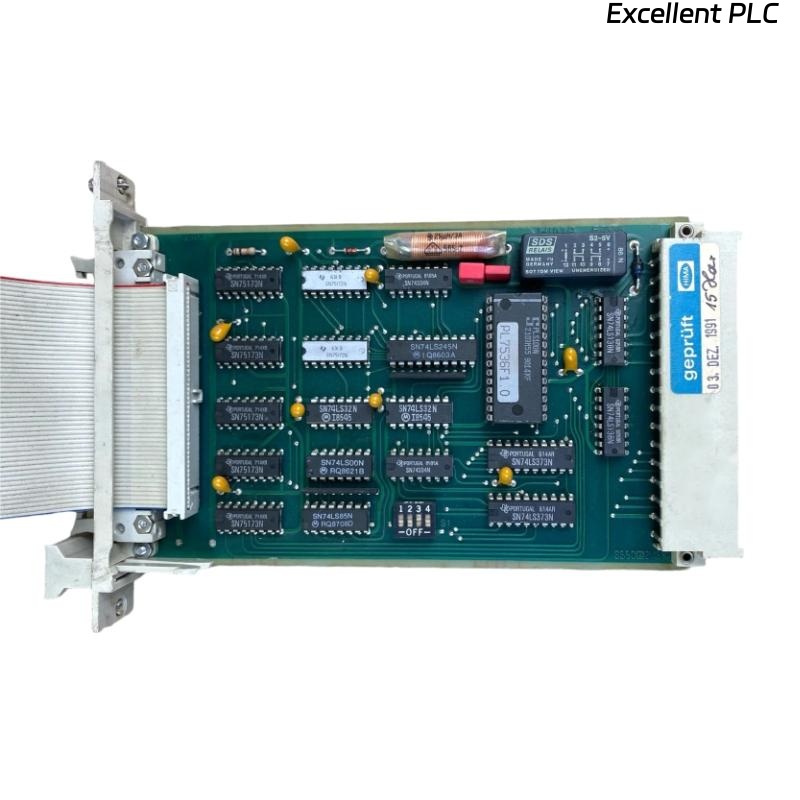

HIMA F8652 Product Overview

The HIMA F8652 is a high-performance safety controller designed for critical industrial applications. It combines advanced safety logic with robust hardware to ensure reliable operation in demanding environments. This product is part of HIMA’s renowned safety system lineup, offering flexibility, scalability, and compliance with international safety standards.

Product Parameters

| Parameter | Specification |

|---|---|

| Dimensions | 200 x 150 x 50mm |

| Weight | 1.2 kg |

| Input Voltage | 24V DC (±10%) |

| Operating Temperature | -20°C to +60°C |

| Safety Integrity Level (SIL) | SIL 3 (IEC 61508) |

| Communication Protocols | PROFIBUS, Ethernet/IP, Modbus TCP |

| Number of I/O Channels | 16 digital inputs, 8 digital outputs |

| Memory Capacity | 4 MB Flash, 512 KB RAM |

| Certifications | ATEX, UL, CE, IECEx |

| MTBF (Mean Time Between Failures) | >100,000 hours |

Product Applications

The HIMA F8652 is widely used in industries where safety is paramount:

-

Oil & Gas: For emergency shutdown systems (ESD) and fire & gas detection.

-

Chemical Processing: Safety interlocks and pressure relief control.

-

Power Generation: Turbine protection and grid stability management.

-

Railway: Signaling and track switching safety.

-

Manufacturing: Machine safety and robotic cell protection.

-

Mining: Hazardous environment monitoring and equipment shutdown.

Product Advantages

-

High Reliability: Designed for 24/7 operation with fail-safe architecture.

-

Modular Design: Easy expansion with additional I/O modules.

-

Global Certifications: Complies with SIL 3, ATEX, and IEC 61508 standards.

-

User-Friendly Configuration: Intuitive software tools for quick setup.

-

Redundancy Support: Dual-channel processing for fault tolerance.

-

Long Service Life: High MTBF reduces maintenance costs.

-

Wide Temperature Range: Suitable for extreme environments.

Frequently Asked Questions (FAQ)

-

What is the SIL rating of the HIMA F8652?

-

It is certified for SIL 3 under IEC 61508.

-

-

Can the F8652 be used in explosive atmospheres?

-

Yes, it is ATEX and IECEx certified for hazardous areas.

-

-

What communication protocols are supported?

-

PROFIBUS, Ethernet/IP, and Modbus TCP.

-

-

Is redundancy possible with this controller?

-

Yes, it supports dual-channel redundancy for critical applications.

-

-

How many I/O points does it support?

-

16 digital inputs and 8 digital outputs (expandable).

-

-

What is the operating temperature range?

-

-20°C to +60°C.

-

-

Does it require special software for configuration?

-

Yes, HIMA’s proprietary Safety Manager Software is used.

-

-

What is the weight of the unit?

-

1.2 kg .

-

-

Can it be integrated with existing PLC systems?

-

Yes, via PROFIBUS or Ethernet/IP.

-

-

What is the typical delivery time?

-

4-6 weeks (subject to order volume).

-

Recommended Related & Popular Models

6 Same-Series/Related Models

| Model | Description | Key Feature |

|---|---|---|

| HIMA F8650 | Compact safety controller | SIL 2, 8 I/O channels |

| HIMA F8655 | High-density I/O version | 32 digital I/O, SIL 3 |

| HIMA F8660 | Redundant safety system | Dual-CPU, SIL 4 |

| HIMA F8630 | Basic safety controller | Cost-effective, SIL 2 |

| HIMA F8670 | Advanced communication module | OPC UA, MQTT support |

| HIMA F8680 | Explosion-proof variant | ATEX Zone 1, SIL 3 |

6 Popular HIMA Models

| Model | Description | Application |

|---|---|---|

| HIMA P34 | Programmable safety system | Process industry |

| HIMA X-CPU | High-speed safety CPU | Power plants |

| HIMA H51q | Modular safety controller | Railway signaling |

| HIMA HIMatrix | Scalable safety platform | Oil & gas refineries |

| HIMA H41q | Compact safety relay | Machine safety |

| HIMA H60 | SIL 4 certified system | Nuclear facilities |

Excellent PLC

Excellent PLC