| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

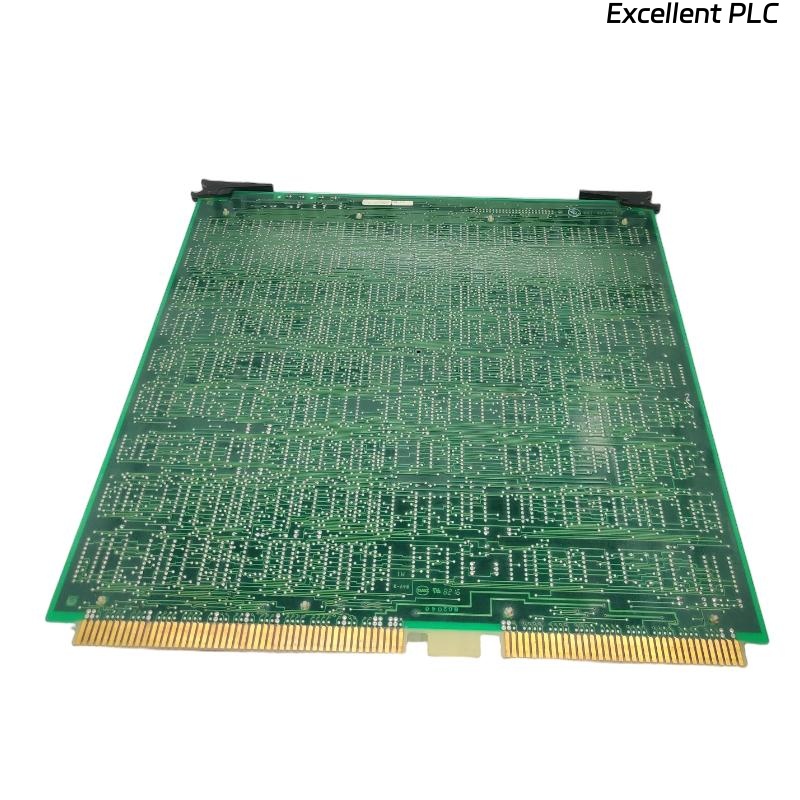

The Honeywell 51401291-100 LCN Control Board is a pivotal component designed for integration within Honeywell’s control systems to manage Logic Control Network (LCN) functions effectively. This control board serves as the central processing unit that interfaces with distributed control modules, enabling precise control, monitoring, and data exchange within complex industrial automation environments.

Built with advanced technology and industrial-grade components, the 51401291-100 ensures robust performance in demanding operational conditions. Its design supports seamless communication with peripheral devices and higher-level control systems, contributing to improved system reliability and operational efficiency. The board’s comprehensive functionality aids in streamlining process control tasks while maintaining system integrity.

Product Specifications

| Parameter | Specification |

|---|---|

| Model Number | 51401291-100 |

| Product Type | LCN (Logic Control Network) Control Board |

| Dimensions (WxHxD) | 260 x 140 x 30 mm |

| Weight | 0.885 kg |

| Operating Voltage | 24 V DC |

| Communication Protocol | Honeywell proprietary LCN protocol |

| Processing Speed | Real-time control with low latency |

| I/O Support | Multiple digital and analog input/output ports |

| Operating Temperature | 0°C to 60°C |

| Diagnostics | Integrated fault detection and status monitoring |

Applications

The Honeywell 51401291-100 LCN Control Board is utilized in a wide range of industrial automation applications such as:

-

Central control of distributed logic modules in Honeywell Experion and other DCS platforms

-

Managing inter-module communication and control in power plants and utility automation

-

Process automation in chemical and petrochemical facilities requiring precise logic control

-

Control of manufacturing processes with complex sequential operations

-

Integration in safety instrumented systems (SIS) for fault-tolerant control

-

Supporting upgrades and expansions of existing control architectures demanding robust LCN management

This control board is fundamental for maintaining synchronized operations and ensuring reliable logic control throughout industrial processes.

Advantages

-

High-Performance Processing: Capable of handling real-time logic control with minimal latency to ensure timely response.

-

Robust Communication: Uses Honeywell’s proprietary LCN protocol for secure and reliable data exchange between modules.

-

Comprehensive Diagnostics: Includes integrated fault detection and status monitoring for proactive system management.

-

Versatile I/O Support: Supports a range of digital and analog signals for flexible control configurations.

-

Durable Industrial Design: Engineered to operate reliably under industrial temperature and environmental conditions.

-

Compact and Lightweight: Facilitates installation in constrained control cabinet spaces.

-

Seamless Integration: Designed for smooth interfacing with Honeywell control systems and distributed modules.

Frequently Asked Questions (FAQ)

-

What communication protocol does the LCN Control Board use?

It uses Honeywell’s proprietary Logic Control Network (LCN) protocol. -

How many I/O ports does the board support?

It supports multiple digital and analog input/output ports for flexible device interfacing. -

What is the operating voltage requirement?

The board operates on 24 V DC. -

Does the board provide real-time processing capabilities?

Yes, it supports real-time control with low latency for precise system response. -

Can this board be integrated with Honeywell Experion systems?

Yes, it is fully compatible with Honeywell Experion and other DCS platforms. -

Is there built-in diagnostic functionality?

Yes, it features integrated fault detection and status monitoring capabilities. -

What temperature range can the board reliably operate within?

The operating temperature range is from 0°C to 60°C. -

Can the board manage communication between multiple distributed modules?

Yes, it is designed to manage inter-module communication effectively within LCN systems. -

Is the board suitable for use in safety instrumented systems (SIS)?

Yes, it can be applied in SIS for fault-tolerant control architectures. -

Does the board require proprietary software for configuration?

Configuration and monitoring are typically done via Honeywell’s control system software suites.

Related Models (Same Series or Similar)

| Model Number | Description | Key Feature |

|---|---|---|

| 51401291-101 | LCN Control Board with Extended I/O | Supports additional I/O ports |

| 51401291-102 | Redundant LCN Control Board | Enhanced reliability with redundancy |

| 51401291-103 | High-Speed LCN Control Board | Faster processing for time-critical applications |

| 51401291-104 | LCN Board with Ethernet Interface | Adds Ethernet communication capabilities |

| 51401291-105 | Compact LCN Control Board | Smaller form factor for tight spaces |

| 51401291-106 | LCN Control Board with Enhanced Diagnostics | Advanced fault detection features |

Popular Honeywell Models (Same Brand)

| Model Number | Description | Application | Key Feature |

|---|---|---|---|

| Experion PKS Controller | Core distributed control system | Process automation | Scalable and reliable control |

| HC900 Hybrid Controller | Modular control system | Small to medium control systems | Flexible and expandable |

| STT800 Temperature Transmitter | Temperature sensing module | Precise temperature measurement | Wide sensor compatibility |

| UDC3500 Process Controller | Process and logic control | Compact control applications | User-friendly interface |

| SmartLine Pressure Transmitter | Pressure measurement | Accurate pressure control | Long-term stability |

| OneWireless Field Devices | Wireless monitoring and control | Remote and difficult access points | Enhanced connectivity |

Excellent PLC

Excellent PLC