| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

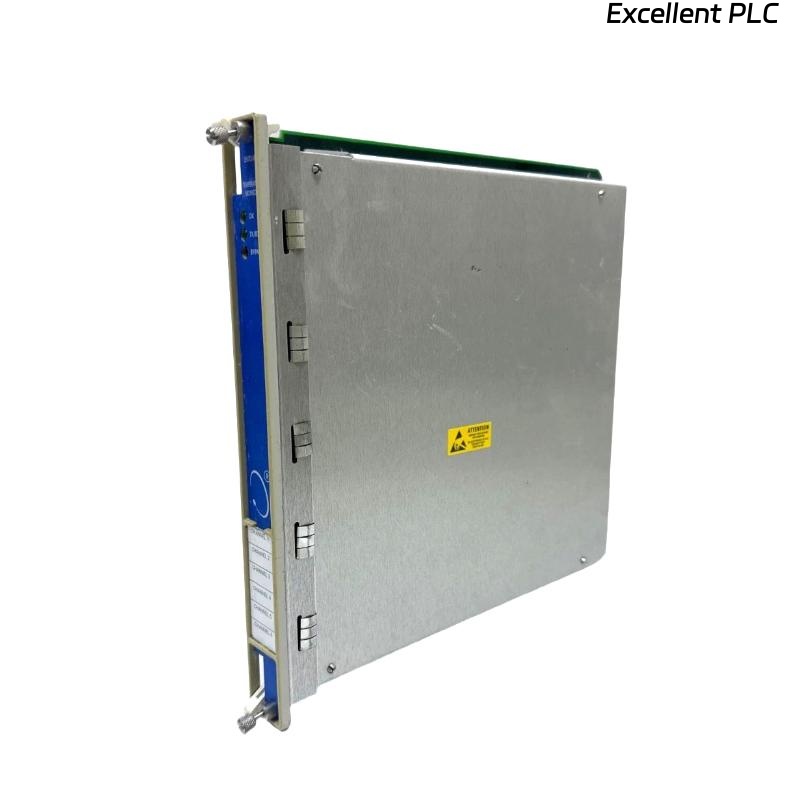

The Bently Nevada 3500/60 Temperature Monitor (modules 133811-01 and 133819-01) is a highly reliable monitoring component within the Bently Nevada 3500 Machinery Protection System. Specifically designed to measure and protect critical assets from abnormal temperature conditions, this monitor ensures that machinery operates within safe thermal limits.

The 3500/60 Temperature Monitor provides continuous monitoring of multiple temperature inputs and communicates directly with the 3500 rack system for integrated alarms, trip functions, and system diagnostics. By processing thermocouple and RTD signals, the module converts temperature data into precise measurements that can be configured for alarms, shutdowns, or system analysis.

This solution is widely deployed in power generation, petrochemical, oil and gas, and heavy industrial environments where accurate thermal monitoring is essential for preventing catastrophic failures and ensuring long-term machinery reliability.

Product Parameters

| Parameter | Specification |

|---|---|

| Manufacturer | Bently Nevada |

| Model | 3500/60 |

| Part Numbers | 133811-01 (Module), 133819-01 (Associated Component) |

| Product Type | Temperature Monitor Module |

| Function | Continuous monitoring of temperature inputs from RTDs and thermocouples |

| Supported Sensors | Resistance Temperature Detectors (RTDs), Thermocouples (various types) |

| Channels | 6 input channels per module |

| Input Range | Configurable per sensor type |

| Accuracy | ±0.1% of full-scale input |

| Signal Processing | Linearization and cold-junction compensation for thermocouples |

| Outputs | Alarm set points, relay outputs, system communication |

| Power Supply | Provided via 3500 Series rack backplane |

| Communication | Integrated with 3500 rack, Modbus outputs available |

| Operating Temperature | 0°C to +60°C |

| Storage Temperature | -40°C to +85°C |

| Humidity | 5% to 95% non-condensing |

| Mounting | Rack-mounted, 3500 chassis |

| Dimensions (H × W × D) | 241.3 x 24.4 x 241.8 mm |

| Weight | 0.91 kg |

Product Applications

The 3500/60 Temperature Monitor is widely applied across industries where accurate thermal monitoring is critical:

-

Gas and Steam Turbines – Detects abnormal bearing and winding temperatures.

-

Compressors – Ensures safe operation under varying process conditions.

-

Pumps – Protects against overheating caused by friction or fluid imbalance.

-

Generators – Provides early warning for winding and cooling system failures.

-

Industrial Furnaces and Heaters – Maintains controlled operating conditions.

-

Petrochemical and Refining Plants – Safeguards critical rotating and process machinery.

Product Advantages

-

High Accuracy Measurement – Ensures precise monitoring with ±0.1% error margin.

-

Wide Sensor Compatibility – Accepts both RTDs and multiple thermocouple types.

-

Multiple Channels – Six independent inputs for flexible monitoring.

-

Advanced Signal Processing – Includes linearization and cold junction compensation.

-

System Integration – Works seamlessly with the Bently Nevada 3500 rack system.

-

Fast Response Alarm Processing – Immediate activation of protective relays during abnormal conditions.

-

Robust Industrial Design – Suitable for demanding operational environments.

-

Configurable Alarms – Custom set points for tailored protection strategies.

FAQ

-

How many temperature input channels does the 3500/60 support?

It supports up to six independent temperature input channels. -

Which types of temperature sensors can be connected?

It supports RTDs and multiple thermocouple types. -

Does the module provide cold junction compensation for thermocouples?

Yes, it includes built-in cold junction compensation. -

What is the measurement accuracy of the temperature monitor?

It provides ±0.1% of full-scale input accuracy. -

Can each channel be configured independently?

Yes, each channel can be configured for sensor type and alarm thresholds. -

Does the 3500/60 integrate with Modbus communication?

Yes, it provides Modbus outputs via the 3500 rack for system integration. -

Are alarm and trip thresholds programmable?

Yes, alarm set points are fully configurable. -

What type of outputs are provided?

Relay outputs for alarms and trips, plus data to the 3500 rack system. -

Is the module redundant-capable?

Yes, it supports redundant configurations for high reliability. -

Can it be used in turbine temperature monitoring applications?

Yes, it is widely used for turbine bearing and winding temperature protection.

Recommended Related Models – Same Series or Similar

| Model | Description | Key Features |

|---|---|---|

| 3500/61 | Temperature Monitor | Multi-channel thermal monitoring, RTD/TC support |

| 3500/65 | Temperature/Process Variable Monitor | Combines process and thermal monitoring |

| 3500/40M | Proximitor Monitor | Vibration and displacement monitoring |

| 3500/42M | Machinery Protection Monitor | Comprehensive machinery protection functions |

| 3500/22M | Transient Data Interface | High-speed data acquisition |

| 3500/45 | Position and Vibration Monitor | Multi-channel shaft vibration and position monitoring |

Popular Bently Nevada Models – Same Brand

| Model | Description | Key Features |

|---|---|---|

| 3500/60 | Temperature Monitor | Monitors RTDs and thermocouples, 6 channels |

| 3500/61 | Advanced Temperature Monitor | Enhanced thermal monitoring, higher configuration options |

| 3500/53 | Overspeed Detection Module | High-speed shaft overspeed protection |

| 3500/22M | Transient Data Interface | Captures transient machinery events |

| 3500/44M | Aeroderivative Gas Turbine Monitor | Specialized for turbine applications |

| 3500/46M | Hydro Monitor | Hydroelectric turbine monitoring |

Excellent PLC

Excellent PLC