| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

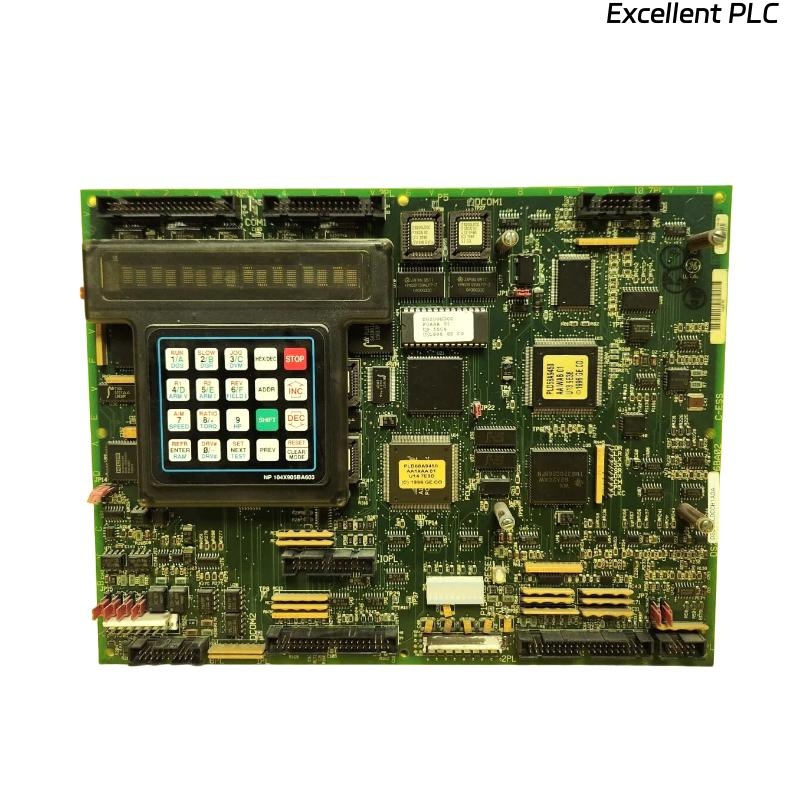

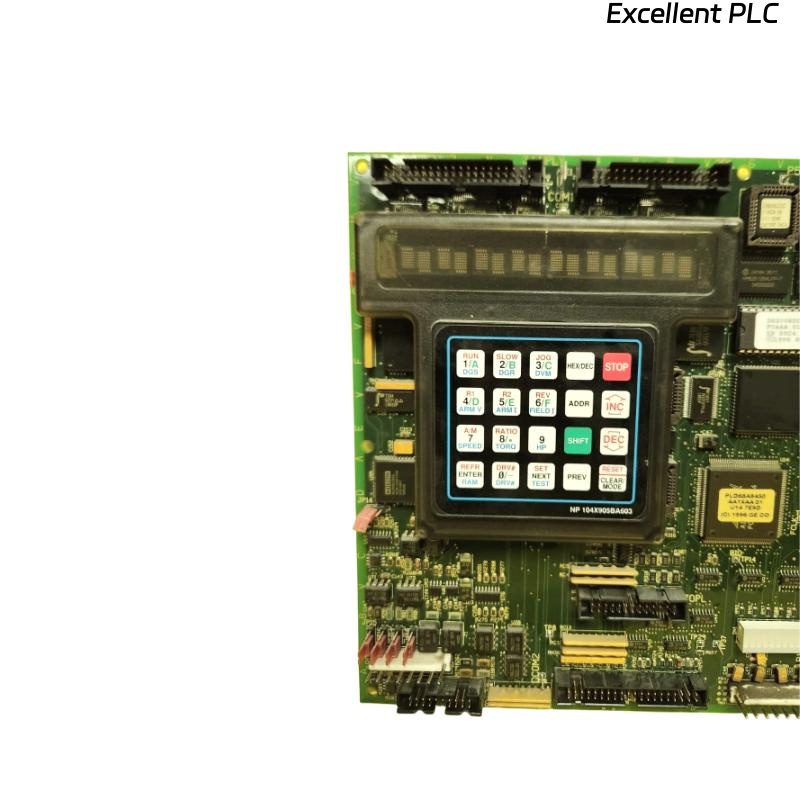

Product Introduction

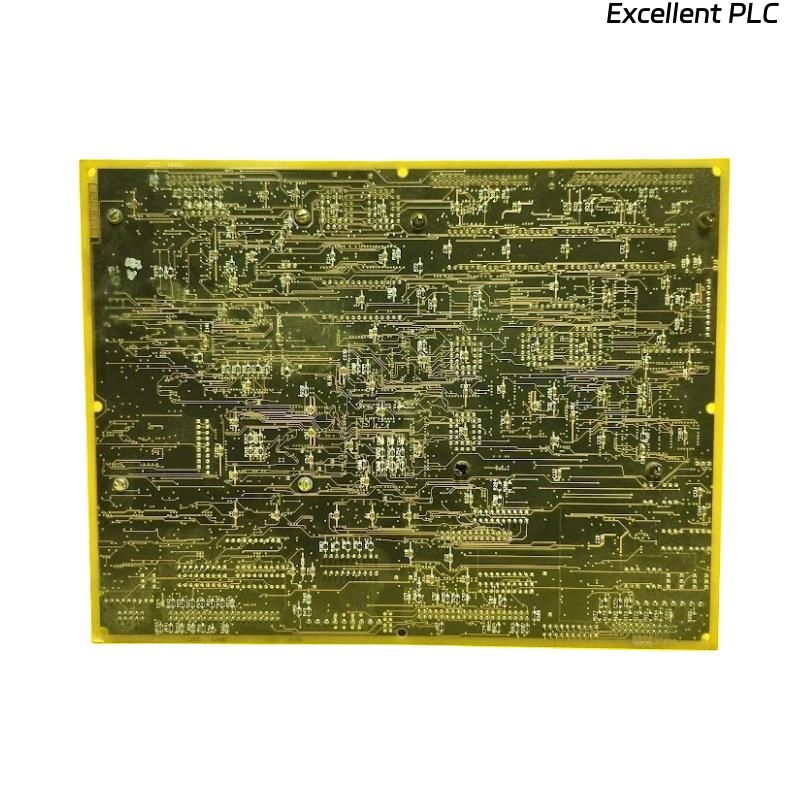

The GE DS200LDCCH1A Drive Control LAN Communications Board is a critical module designed for high-speed communication within GE’s industrial drive control systems. This board enables reliable data exchange between drive control modules, supervisory systems, and remote monitoring devices via Local Area Network (LAN) interfaces. It ensures seamless integration, rapid data transfer, and real-time monitoring capabilities, making it essential for complex automation and control networks in power generation, industrial, and process applications.

The DS200LDCCH1A is engineered for high-performance environments, supporting multiple communication protocols while maintaining signal integrity and low latency. Its robust design ensures stable operation under electromagnetic interference, temperature variations, and industrial vibration, providing a reliable backbone for distributed drive control systems.

Product Parameters

| Parameter | Description |

|---|---|

| Product Model | GE DS200LDCCH1A |

| Product Type | Drive Control LAN Communications Board |

| Function | Facilitates LAN-based data communication between drive control modules and supervisory systems |

| Supported Protocols | Modbus TCP/IP, GE proprietary LAN protocols |

| Data Rate | Up to 100 Mbps typical |

| Input Signals | Digital communication signals from drive and control modules |

| Output Signals | LAN communication signals to connected devices and systems |

| Operating Temperature | 0°C – 70°C |

| Dimensions | 330 × 178 mm |

| Weight | 0.454 kg |

| Mounting | Rack-mounted in standard GE drive control system enclosures |

| Isolation | Galvanically isolated communication ports to reduce signal interference |

Product Applications

-

Industrial Drive Control Systems: Provides reliable LAN communication for high-power drive controllers in industrial plants.

-

Power Plant Automation: Integrates with turbine and generator control networks for real-time monitoring and control.

-

Process Control Networks: Supports communication between distributed drives, I/O modules, and supervisory control systems.

-

Remote Monitoring: Enables remote diagnostics and control of drive systems over secure LAN networks.

-

Redundant Network Architectures: Can be deployed in dual LAN configurations for increased reliability and system availability.

Product Advantages

-

High-Speed Communication: Supports fast data transfer to ensure timely updates for real-time drive control.

-

Protocol Flexibility: Compatible with multiple LAN protocols, enabling integration with diverse control systems.

-

Industrial Reliability: Designed to withstand high temperatures, vibrations, and electrical noise in industrial environments.

-

Signal Isolation: Galvanically isolated ports protect sensitive components from interference and backfeed.

-

System Integration: Seamlessly integrates with GE drive control modules, reducing setup complexity.

-

Redundancy Support: Can operate in parallel LAN networks to maintain system reliability in case of failure.

FAQ

-

What is the primary function of the DS200LDCCH1A?

It facilitates reliable LAN-based communication between drive control modules, supervisory systems, and remote monitoring devices. -

Which communication protocols are supported?

The board supports Modbus TCP/IP and GE proprietary LAN protocols, ensuring compatibility with various industrial control systems. -

Can it handle multiple devices on the network simultaneously?

Yes, it supports multiple connections with isolation for each channel to prevent data collisions. -

How fast is the data transfer?

Typical data transfer rates are up to 100 Mbps, sufficient for real-time control and monitoring. -

Is the board suitable for high-vibration industrial environments?

Yes, it is designed with industrial-grade components to tolerate vibration and harsh environmental conditions. -

How is signal interference minimized?

Galvanic isolation of communication ports and optimized PCB layout reduce interference and prevent signal degradation. -

Can it support redundant LAN configurations?

Yes, the board can be deployed in parallel networks for redundancy, ensuring continuous system operation. -

What devices can it interface with?

It interfaces with GE drive control modules, I/O modules, and supervisory control systems for data exchange and monitoring. -

How is the board installed?

The board mounts in standard GE drive control system racks and connects via backplane and LAN connectors. -

Can it be used in remote monitoring applications?

Yes, it enables remote diagnostics and control over secure LAN connections for distributed drive systems.

Recommended Related Models (Same Series or Related)

| Model Number | Description | Weight |

|---|---|---|

| DS200LDCCH1B | Alternate LAN Communication Board for Drive Control | 1.42 kg |

| DS200LDCCH2A | Dual-port Drive Control LAN Board | 1.45 kg |

| DS200DSPXH1D | Digital Signal Processor Control Board | 1.10 kg |

| DS200EXAMG1A | Exciter Auxiliary Board | 1.42 kg |

| DS200TREGH1B | Turbine Regulator Board | 1.35 kg |

| DS200TRLYH1B | Relay Output Board for Drive Control | 1.15 kg |

Popular GE Models (Same Brand, Different Applications)

| Model Number | Description | Weight |

|---|---|---|

| IS200DSPXH1D | Digital Signal Processor Control Board | 1.10 kg |

| IS200ERBPG1A | Exciter Regulator Backplane | 1.50 kg |

| IS200ESELH3A | Exciter Selector Board | 1.35 kg |

| DS200FGPAG1AGD | Gate Pulse Amplifier Board | 1.42 kg |

| IS200VVIBH1C | Vibration Monitoring Board | 0.98 kg |

| IS200ACPG1A | Power Supply and Control Board | 1.55 kg |

Excellent PLC

Excellent PLC