| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

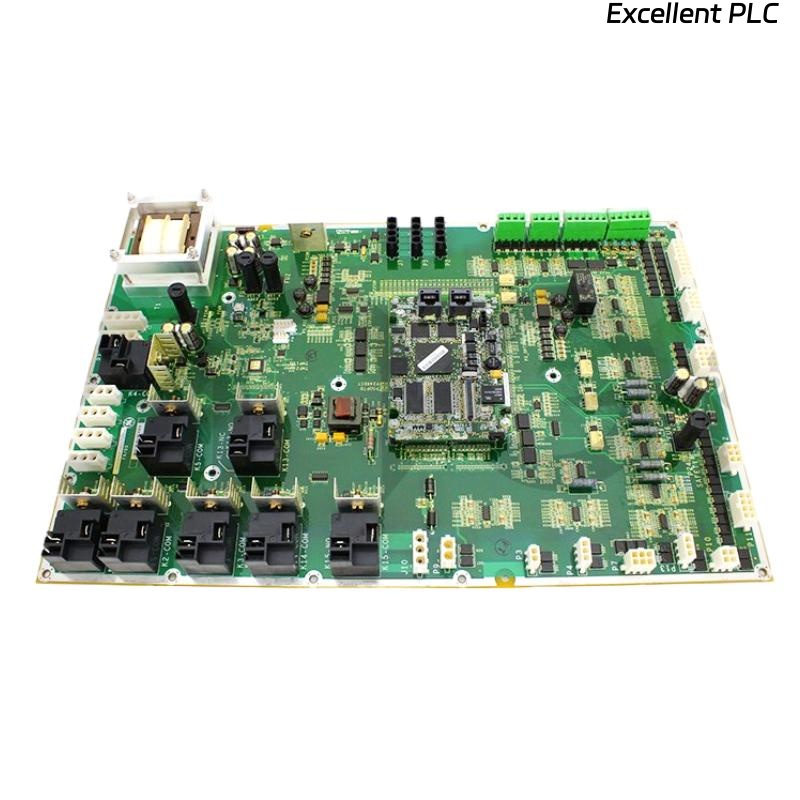

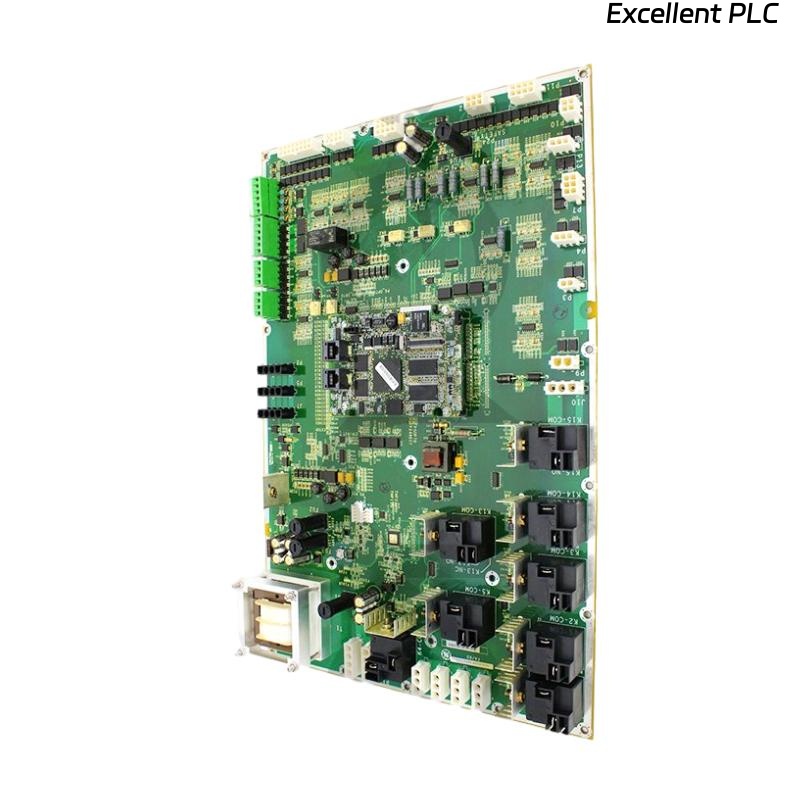

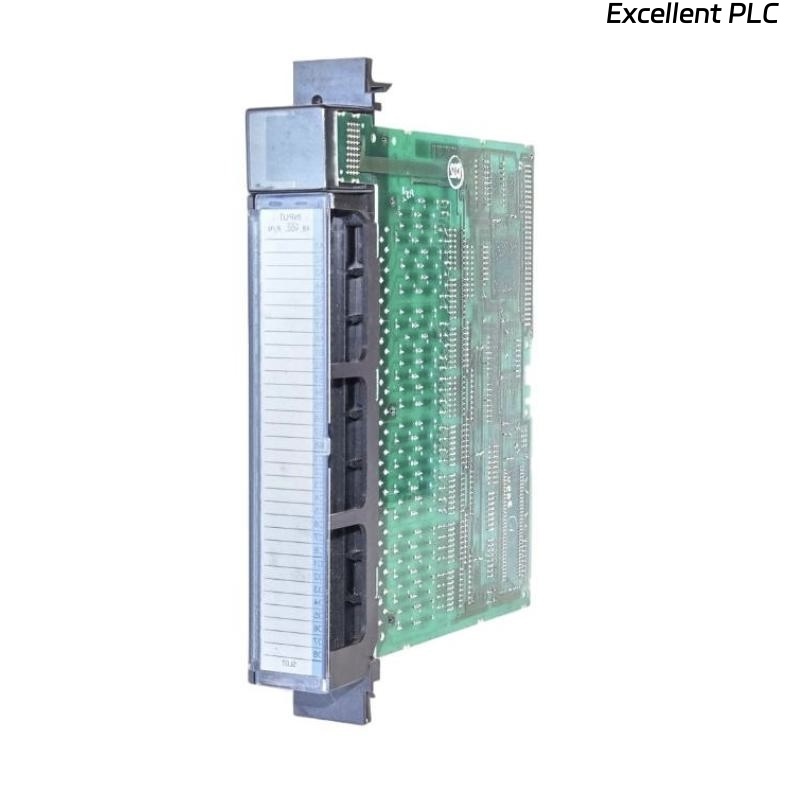

The GE IS215WEMAH1BB Wind Energy Main Cabinet Board is a critical control module designed for integration into GE Wind Energy Control Systems, serving as the main interface for turbine control, monitoring, and protection. It functions as the central processing unit for wind turbine electrical and mechanical operations, coordinating inputs from sensors, executing control algorithms, and generating output commands for actuators and protection systems.

This main cabinet board is engineered to handle high-speed signal processing, fault detection, and control logic execution in large-scale wind turbines. Its design ensures reliable operation in harsh offshore and onshore wind environments, including extreme temperature, humidity, and vibration conditions. The IS215WEMAH1BB combines advanced digital processing, redundant pathways, and robust industrial-grade construction to provide continuous turbine operation and safety.

Product Specifications

| Parameter | Specification |

|---|---|

| Model Number | IS215WEMAH1BB |

| Product Type | Wind Energy Main Cabinet Board |

| System Compatibility | GE Wind Energy Control Systems |

| Input/Output Channels | Multiple analog/digital sensor inputs, actuator control outputs |

| Processing Unit | High-speed embedded processor for real-time control |

| Memory | Onboard RAM and non-volatile flash memory |

| Power Supply | +5 VDC, +12 VDC via cabinet backplane |

| Operating Temperature | -20°C to +60°C |

| Storage Temperature | -40°C to +85°C |

| Humidity | 5% to 95% non-condensing |

| Cooling | Forced-air convection through cabinet |

| Mechanical Build | Industrial-grade PCB with reinforced connectors |

| Compliance | CE, UL, CSA industrial standards |

| Dimensions | 264.1 x 213.3 mm |

| Weight | 0.4 kg |

Applications

The IS215WEMAH1BB board is deployed in wind turbines requiring reliable real-time control and protection:

-

Onshore and Offshore Wind Turbines: Centralized control of pitch, yaw, and generator systems.

-

Turbine Power Regulation: Manages power output to the grid under variable wind conditions.

-

Turbine Protection: Monitors overspeed, overcurrent, and vibration for safe operation.

-

Wind Farm Control Integration: Interfaces with supervisory SCADA systems for monitoring multiple turbines.

-

Yaw and Pitch Actuation Control: Coordinates blade and nacelle orientation with wind conditions.

-

Condition Monitoring: Supports vibration, temperature, and torque sensor inputs for predictive maintenance.

Advantages

-

Centralized Control: Integrates monitoring, protection, and actuation control in one board.

-

Real-Time Processing: Ensures immediate response to abnormal wind or mechanical conditions.

-

Industrial-Grade Reliability: Designed to operate in harsh wind farm environments.

-

Redundancy Support: Compatible with redundant configurations for high availability.

-

Flexible Integration: Interfaces seamlessly with GE Wind SCADA and supervisory systems.

-

Comprehensive Protection Functions: Monitors overspeed, vibration, overcurrent, and mechanical faults.

-

Maintenance-Friendly Design: Modular construction simplifies installation and service.

-

Certified for Industrial Standards: CE, UL, and CSA compliance ensures operational safety.

FAQ

-

What is the primary function of the IS215WEMAH1BB board?

It serves as the main control and protection module for GE wind turbines, processing sensor inputs and generating actuator commands. -

Which wind turbine systems are compatible with this board?

It is compatible with GE Wind Energy Control Systems in both onshore and offshore turbines. -

Does it support real-time turbine protection?

Yes, it continuously monitors overspeed, vibration, and electrical parameters to trigger protective actions. -

Can it operate in redundant configurations?

Yes, it can be configured in redundant architectures for high system availability. -

What type of sensors can be connected to this board?

It supports vibration, speed, torque, temperature, and electrical current sensors. -

How are actuator outputs managed?

Through dedicated digital and analog control channels integrated with the turbine pitch, yaw, and generator systems. -

What power supply does the board require?

It draws +5 VDC and +12 VDC from the wind turbine control cabinet backplane. -

Is it suitable for offshore wind turbine environments?

Yes, it is designed to handle high humidity, vibration, and temperature variations common in offshore conditions. -

Can firmware be updated on this module?

Yes, using GE wind system integration and diagnostic tools. -

What industrial standards does this board meet?

It complies with CE, UL, and CSA certifications for industrial control and turbine protection.

Related Models in the Same Series

| Model | Description |

|---|---|

| IS215WEMAH1BC | Wind Energy Main Cabinet Board, alternative configuration |

| IS215WEMAH2BB | Redundant main cabinet board for high-reliability turbines |

| IS215WEPIDH1A | Wind turbine pitch interface and control board |

| IS215WESCCH1B | Wind turbine supervisory control interface board |

| IS215WEVIBH1C | Vibration monitoring board for wind turbines |

| IS215WEGENH1D | Generator interface and protection board |

Popular GE Models

| Model | Description |

|---|---|

| IS200SPIDG1A | Speed Input Module for wind turbine monitoring |

| IS200TBAIH1C | Analog Input Terminal Board |

| IS215ACLEH1A | Application Control Layer Module |

| IS200TRLYH1B | Relay Output Board |

| IS200VVIBH1C | Vibration Monitoring Board |

| IS215VCMIH2BE | VME Bus Master Controller Board |

Excellent PLC

Excellent PLC