| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

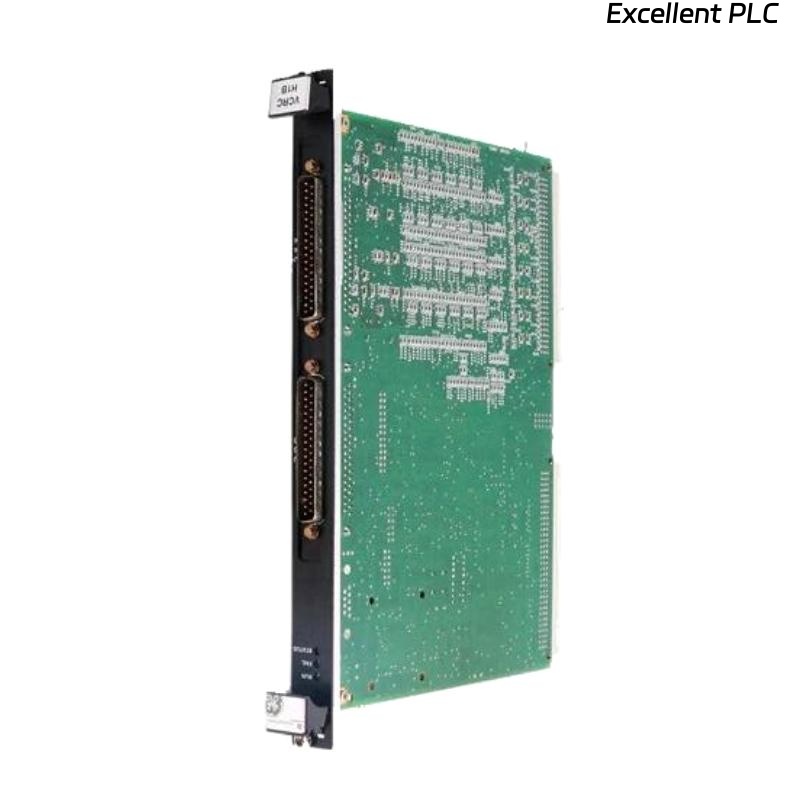

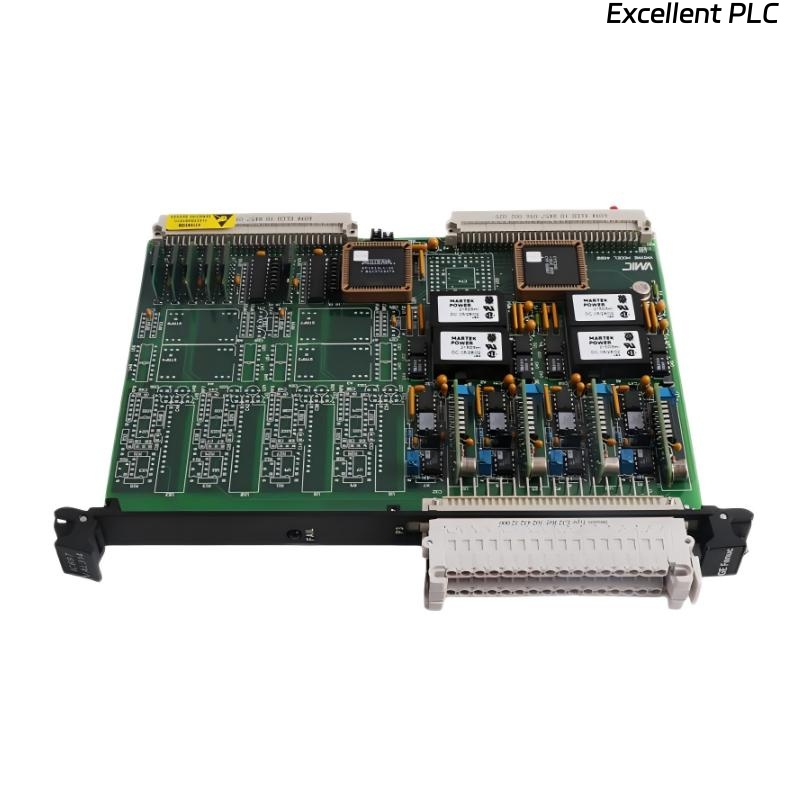

The GE IS200AECPH1CCB is a high-performance control board from the Mark VI Series, designed specifically for industrial and power generation applications requiring reliable process control. This board provides critical interfacing and signal processing functions to the Mark VI control system, ensuring seamless communication with sensors, actuators, and other automation equipment. Engineered for precision and robustness, the IS200AECPH1CCB enhances system stability, reduces process variability, and ensures high uptime in demanding environments. Its modular design allows for straightforward integration and maintenance, making it a preferred choice for power plants, marine propulsion, and industrial process control systems.

Product Specifications

| Parameter | Value |

|---|---|

| Model | IS200AECPH1CCB |

| Series | Mark VI Series |

| Function | Process Control Interface Board |

| Input Voltage | 24 V DC nominal |

| Power Consumption | 12 W typical |

| Communication Protocol | MODBUS / DeviceNet / Ethernet optional |

| I/O Channels | 32 digital / 16 analog configurable |

| Processor Type | 32-bit Microcontroller |

| Memory | 512 KB Flash, 128 KB SRAM |

| Operating Temperature | -20°C to +70°C |

| Storage Temperature | -40°C to +85°C |

| Humidity | 5–95% non-condensing |

| Mounting | Rack-mounted / DIN rail compatible |

| Dimensions (L × W × H) | 250 × 120 × 35 mm |

| Weight | 0.9 kg |

| Protection Rating | IP20 |

| Isolation | 1500 V optical isolation for I/O signals |

| Certification | CE, UL recognized |

Applications

The IS200AECPH1CCB is widely used across industries that require precise monitoring, control, and automation:

-

Power Generation: Steam turbines, gas turbines, and combined-cycle plants for process control and monitoring.

-

Industrial Automation: Chemical, petrochemical, and refining plants for process optimization.

-

Marine Applications: Propulsion control systems and auxiliary plant automation.

-

Oil & Gas: Drilling and production platforms for critical process instrumentation.

-

Renewable Energy: Wind turbine control and hydroelectric plant monitoring.

-

Safety Systems: Emergency shutdown logic and high-availability control networks.

Advantages

-

Reliable Performance: Designed to maintain operation in harsh industrial environments with wide temperature and humidity tolerance.

-

High Precision Control: Capable of processing high-speed signals for accurate process regulation.

-

Modular Integration: Supports easy replacement and integration into Mark VI control racks.

-

Advanced Communication: Supports multiple industrial protocols, ensuring compatibility with a variety of devices.

-

Robust Isolation: 1500 V optical isolation protects system from electrical surges and interference.

-

Scalable Design: Configurable I/O channels allow adaptation to different process requirements.

-

Energy Efficient: Low power consumption minimizes thermal load on the control system.

-

Maintenance Friendly: LED status indicators and modular design simplify troubleshooting and replacement.

FAQ

-

What communication protocols does the IS200AECPH1CCB support?

The board supports MODBUS, DeviceNet, and optional Ethernet communication for system integration. -

Can the board handle both digital and analog inputs simultaneously?

Yes, it supports 32 digital channels and 16 analog channels simultaneously. -

What is the operating temperature range of the control board?

The board operates reliably from -20°C to +70°C. -

Is the board compatible with previous Mark VI systems?

Yes, it is backward compatible with existing Mark VI control racks. -

What kind of isolation protection does the board provide?

It features 1500 V optical isolation on I/O channels to protect against electrical surges. -

What is the power consumption of the IS200AECPH1CCB?

Typical power consumption is 12 W under nominal operation. -

Can the board be mounted on DIN rails?

Yes, it supports both rack-mounted and DIN rail installation. -

What type of processor does the control board use?

The board is equipped with a 32-bit microcontroller for high-speed signal processing. -

Does the board include non-volatile memory?

Yes, it has 512 KB Flash memory for configuration storage and 128 KB SRAM for runtime operations. -

What protection rating does the board have?

The board is rated IP20 for protection against solid objects and limited moisture exposure.

Related Models (Same Series / Similar Models)

| Model | Function | I/O Channels | Weight | Notes |

|---|---|---|---|---|

| IS200AECPH1CAA | Process Control Interface Board | 24/8 | 0.85 kg | Standard Mark VI variant |

| IS200AECPH1CCN | Control Board with Ethernet | 32/16 | 0.95 kg | Optional Ethernet integration |

| IS200AECPH2CCB | Dual-Channel Process Control Board | 64/32 | 1.2 kg | High I/O capacity |

| IS200AECPH1DCB | Digital Control Interface | 40/0 | 0.9 kg | Focus on digital I/O |

| IS200AECPH1ACB | Analog Control Board | 16/16 | 0.88 kg | Optimized for analog signals |

| IS200AECPH3CCB | Advanced Mark VI Control Board | 48/24 | 1.1 kg | Enhanced communication options |

Popular Models (Same Brand – GE / Mark VI)

| Model | Function | I/O Channels | Weight | Notes |

|---|---|---|---|---|

| IS200AECPH1CAB | Standard Mark VI Control Board | 24/8 | 0.85 kg | Widely used in power plants |

| IS200AECPH2CAB | High-Capacity Control Board | 48/24 | 1.1 kg | Used in large industrial setups |

| IS200AECPH1DAC | Digital-Only Control Board | 32/0 | 0.9 kg | Optimized for discrete signals |

| IS200AECPH1AAC | Analog-Only Control Board | 16/16 | 0.88 kg | For precision analog processes |

| IS200AECPH3CAC | Advanced Multi-Protocol Board | 48/32 | 1.15 kg | Supports multiple communication protocols |

| IS200AECPH2DCC | Dual-Channel High-Speed Board | 64/32 | 1.2 kg | High-speed process control |

Excellent PLC

Excellent PLC