| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

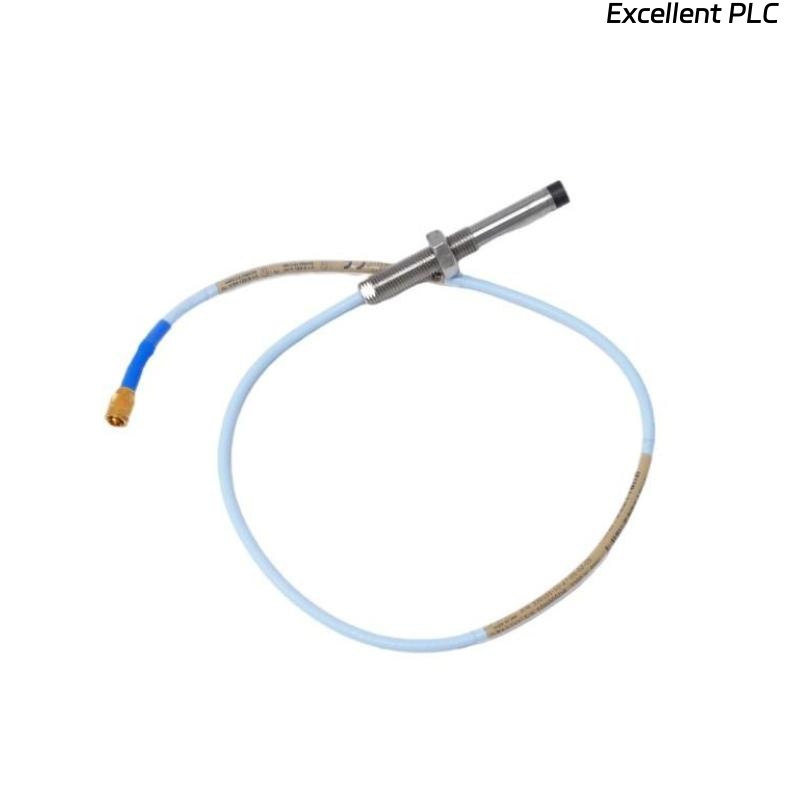

The Bently Nevada 330901-00-09-70-02-05 3300 NSv Proximity Probe is a precision-engineered, non-contact sensor developed for high-speed, small-shaft rotating machinery that demands accurate vibration and displacement monitoring in limited-space installations. As a key member of the Bently Nevada 3300 NSv (Narrow Side-view) family, it ensures real-time measurement of shaft vibration, radial position, and dynamic movement. Its compact design, rugged stainless-steel housing, and proven eddy-current sensing technology make it ideal for use in harsh industrial environments such as petrochemical refineries, power generation plants, and heavy-duty compressor systems. Engineered for integration with Bently Nevada 3300 and 3500 monitoring systems, the probe provides unmatched reliability for predictive maintenance and machinery protection.

Product Specifications

| Parameter | Details |

|---|---|

| Model Number | 330901-00-09-70-02-05 |

| Series | 3300 NSv (Narrow Side-view) |

| Sensing Principle | Eddy-current non-contact displacement |

| Measurement Range | 0 to 2.0 mm (80 mils) |

| Linearity | ±0.25% of full scale |

| Frequency Response | DC to 10 kHz |

| Probe Tip Diameter | 5 mm |

| Power Supply (via proximitor) | –24 V DC nominal |

| Output Signal | Proportional voltage compatible with Bently Nevada monitoring systems |

| Operating Temperature Range | –35 °C to +177 °C (–31 °F to +350 °F) |

| Environmental Protection | IP67, resistant to dust, oil, and industrial contaminants |

| Total Length | 7 meters |

| Weight | 0.15 kg |

| Compliance/Certifications | CE, RoHS |

Applications

The 330901-00-09-70-02-05 probe is specifically designed for tight-space and high-speed machinery monitoring, including:

-

Small gas and steam turbines in power generation facilities

-

High-speed compressors and critical process pumps

-

Industrial fans, blowers, and motors operating in harsh conditions

-

Petrochemical and refinery rotating equipment requiring continuous vibration data

-

Gearboxes and auxiliary equipment integrated with Bently Nevada 3300/3500 monitoring systems

Advantages

-

Compact Form Factor – 5 mm probe diameter fits into constrained spaces without sacrificing measurement accuracy.

-

High Accuracy – Maintains ±0.25% linearity for reliable vibration and displacement measurement.

-

Rugged Build – Stainless-steel body and IP67 environmental sealing protect against moisture, dust, and industrial contaminants.

-

Wide Temperature Tolerance – Operates reliably from –35 °C to +177 °C with built-in temperature compensation.

-

Seamless System Integration – Fully compatible with Bently Nevada 3300 and 3500 monitoring platforms.

-

Low Maintenance – Non-contact sensing eliminates mechanical wear and extends operational reliability.

FAQ

-

What sensing technology is used in the 330901-00-09-70-02-05 probe?

It employs eddy-current non-contact displacement technology for precise vibration monitoring. -

How is the probe connected to a Bently Nevada monitoring system?

It is paired with a factory-matched extension and proximitor driver to maintain calibration accuracy. -

Can this probe be mounted in any orientation?

Yes, it supports horizontal, vertical, or angled mounting when the proper shaft-to-probe gap is maintained. -

What is the recommended probe-to-target gap for optimal performance?

Typically 1.0 mm ±0.2 mm, depending on the target material and system configuration. -

Is this probe suitable for use in hazardous or explosive environments?

Yes, when installed with certified intrinsically safe barriers or protective enclosures. -

What is the maximum frequency response of this proximity probe?

It delivers a flat frequency response from DC up to approximately 10 kHz. -

Can it measure vibration on non-metallic shafts?

No, the probe requires a conductive metallic target for accurate eddy-current sensing. -

Does temperature variation affect measurement stability?

Built-in temperature compensation minimizes output drift across the full operating range. -

What type of output signal is provided by the probe?

It provides a proportional voltage signal compatible with Bently Nevada monitoring equipment. -

Is special shielding required in high electromagnetic interference areas?

Proper cable shielding and grounding are recommended to maintain signal integrity.

Related Models (Same Series)

| Model Number | Key Feature |

|---|---|

| 330901-00-08-05-02 | Compact version with 0.5 m configuration |

| 330901-00-08-10-02 | 1.0 m configuration for flexible installations |

| 330901-00-08-15-02 | Extended configuration with 1.5 m setup |

| 330901-00-07-05-02 | 7 mm tip for broader sensing area |

| 330901-00-09-10-02 | High-frequency design for ultra-fast machinery |

| 330901-00-08-20-02 | Long-range version for remote equipment placement |

Popular Bently Nevada Models

| Model Number | Primary Application |

|---|---|

| 330500 | General-purpose proximity probe for industrial motors |

| 3500/22M | Machinery protection and monitoring module |

| 330180 | High-speed keyphasor proximity probe |

| 3701/40 | Compact machinery condition monitoring transmitter |

| 330103 | Short-length probe for confined installations |

| 330400 | High-temperature probe for turbine and compressor use |

Excellent PLC

Excellent PLC