| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

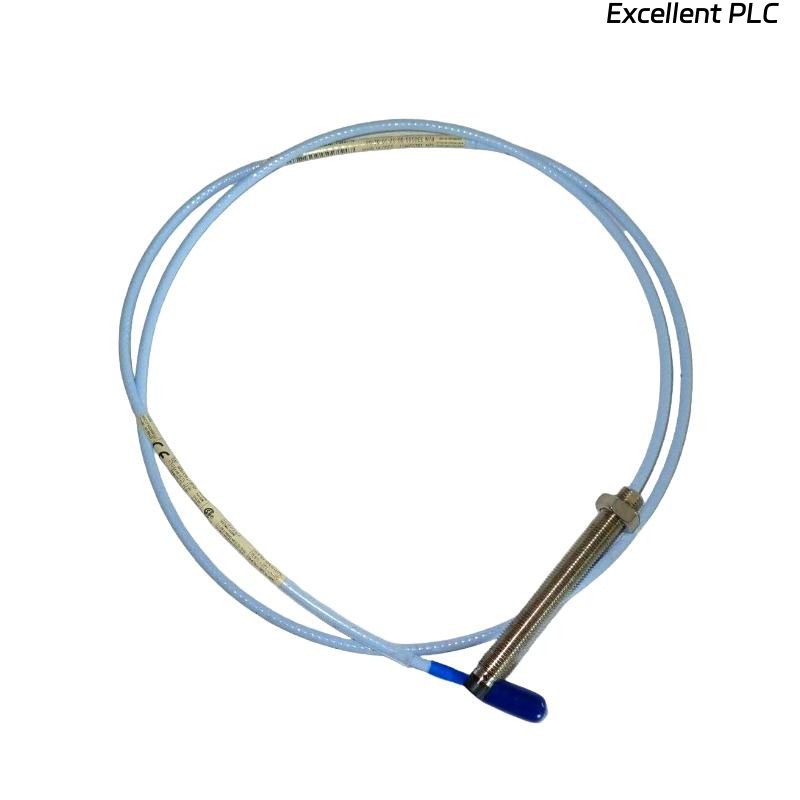

The Bently Nevada 330904-00-24-10-02-05 3300 NSv Proximity Probe is a precision, non-contact displacement and vibration monitoring sensor designed for industrial rotating machinery. Utilizing high-frequency eddy current technology, it provides accurate and reliable measurement of shaft position, vibration, and proximity without physical contact, reducing mechanical wear and maintenance needs. With a robust construction and proven industrial reliability, this probe is ideal for integration into turbines, compressors, generators, pumps, and other critical machinery. Its performance enables predictive maintenance, early fault detection, and continuous process monitoring, ensuring operational safety and efficiency.

Product Specifications

| Parameter | Details |

|---|---|

| Model Number | 330904-00-24-10-02-05 |

| Sensor Type | 3300 NSv Proximity Probe |

| Total Length | 1 meter |

| Weight | 0.15 kg |

| Measurement Principle | Eddy Current |

| Output Signal | AC signal proportional to displacement |

| Linearity | ±1% of full scale |

| Temperature Range | –40 °C to +125 °C |

| Frequency Response | 0–10 kHz |

| Cable Type | Shielded coaxial cable |

| Sensor Head Material | Stainless steel, corrosion-resistant |

| Mounting Type | Threaded or flanged mount options |

| Connector Type | Industrial or MIL-spec connector |

Applications

-

Turbines – Continuous monitoring of rotor displacement and vibration.

-

Compressors – Detects shaft misalignment, imbalance, or excessive vibration.

-

Generators – Provides reliable feedback for shaft position and vibration analysis.

-

Pumps – Monitors high-speed shaft movement and vibration for early anomaly detection.

-

Industrial Motors – Ensures precise rotor monitoring to maintain efficiency.

-

Rotating Machinery – Integrated into vibration monitoring systems to enhance operational reliability.

Advantages

-

Non-Contact Measurement – Minimizes mechanical wear, ensuring long-term operation.

-

High Accuracy – ±1% full-scale linearity provides precise and repeatable readings.

-

Robust Construction – Stainless steel sensor housing offers corrosion resistance.

-

Compact and Lightweight – 1-meter total length and 0.15 kg weight facilitate easy installation.

-

Wide Temperature Range – Functions reliably from –40 °C to +125 °C.

-

High-Frequency Response – Capable of capturing dynamic events up to 10 kHz.

-

Flexible Mounting Options – Threaded or flanged for versatile industrial installation.

-

Stable Output – Compatible with industrial DCS, vibration monitoring, and data acquisition systems.

FAQ

-

What type of signal does the 330904-00-24-10-02-05 output?

The sensor outputs an AC voltage proportional to shaft displacement, suitable for integration with DCS, monitoring systems, and vibration data acquisition. -

What is the operating range for this proximity probe?

The standard measurement range provides accurate readings within ±1 mm of the target shaft surface. -

Can it be installed on high-speed rotors?

Yes, its high-frequency response up to 10 kHz ensures accurate measurements on high-speed rotating machinery. -

How is this probe mounted to equipment?

It supports both threaded and flanged mounting configurations, allowing flexible installation on various machinery types. -

What material is the sensor head made of?

The sensor head is constructed from stainless steel and is corrosion-resistant, suitable for harsh industrial environments. -

Can it detect shaft misalignment or imbalance?

Yes, displacement and vibration readings can identify early signs of misalignment, imbalance, or rotor instability. -

What temperature range can this probe operate within?

It reliably functions between –40 °C and +125 °C, suitable for most industrial applications. -

What type of cable should be used with this probe?

A shielded coaxial cable is recommended to minimize electrical noise, and custom cable lengths can be provided. -

What is the linearity accuracy of the probe?

The sensor maintains ±1% full-scale linearity to ensure precise measurement across the operating range. -

Can it be integrated with existing monitoring systems?

Yes, the probe is compatible with standard industrial vibration monitoring systems, DCS, and signal processing platforms.

Related Models (Same Series)

| Model Number | Key Feature |

|---|---|

| 330904-00-24-10-02-01 | Standard 3300 NSv probe for general applications |

| 330904-00-24-10-02-02 | High-frequency response variant |

| 330904-00-24-10-02-03 | Reinforced housing for extreme environments |

| 330904-00-24-10-02-04 | Probe with integrated industrial connector |

| 330904-00-24-10-02-06 | Adjustable measurement range for customized machinery |

| 330904-00-24-10-02-07 | Precision linearity variant for critical equipment monitoring |

Popular Bently Nevada Models

| Model Number | Primary Application |

|---|---|

| 330900-70-05 | Proximity sensor for turbine and generator monitoring |

| 330901-00-08-05-02-RU | 3300 NSv probe for standard displacement monitoring |

| 330901-00-12-05-02-RU | High-precision proximity sensor for rotating machinery |

| 330901-00-32-05-02-CN | Industrial NSv probe for pumps and motors |

| 330901-22-40-10-01 | 3300 NSv probe optimized for high-speed applications |

| 330901-31-54-05-02-00 | Extended range NSv probe for turbines and compressors |

Excellent PLC

Excellent PLC