| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

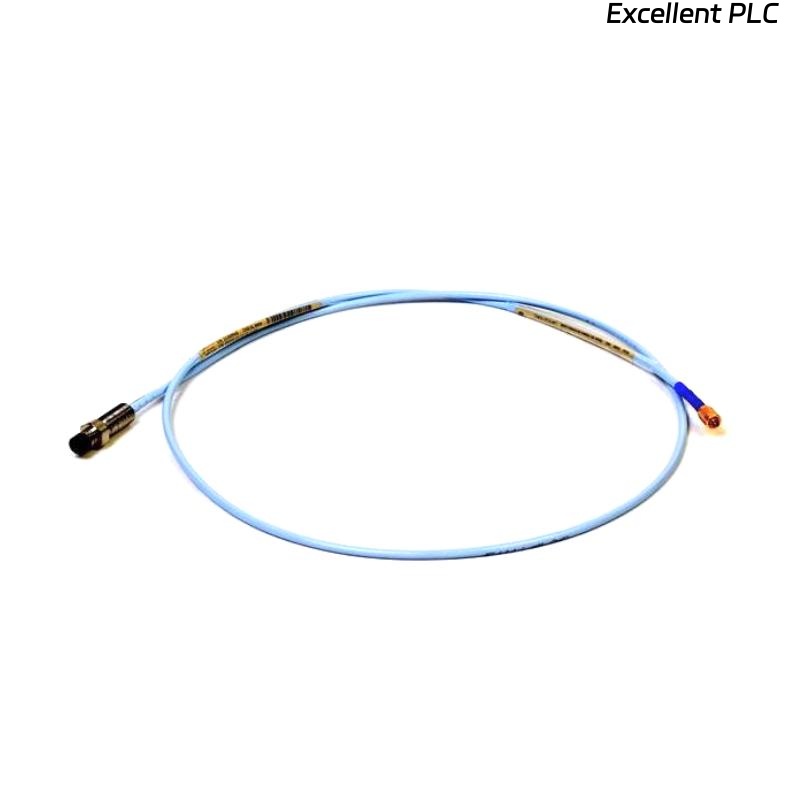

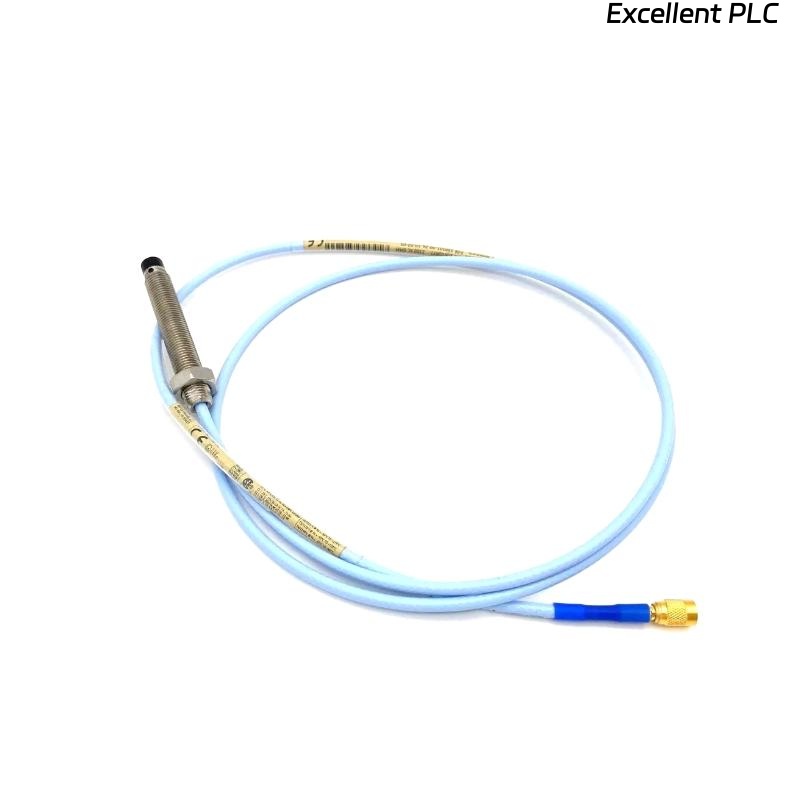

The Bently Nevada 330905-00-05-50-02-00 3300 NSv Proximity Probe is a precision non-contact vibration and displacement sensor designed for critical machinery monitoring and protection. As part of the 3300 NSv (Narrow Side View) series, this probe is specifically engineered for applications where long cable length is required without compromising signal integrity or measurement accuracy. It employs advanced eddy-current technology to deliver precise real-time detection of shaft displacement and vibration, enabling early fault detection and predictive maintenance. Its robust stainless-steel construction and hermetic sealing make it suitable for harsh industrial environments, ensuring long-term reliability for turbines, compressors, motors, and other rotating machinery.

Technical Specifications

| Parameter | Description |

|---|---|

| Model Number | 330905-00-05-50-02-00 |

| Series | 3300 NSv Proximity Probe |

| Total Length | 5 meters |

| Weight | 0.15 kg |

| Sensing Principle | Eddy current, non-contact displacement measurement |

| Tip Diameter | 5 mm (nominal) |

| Linear Range | 0.25 mm to 2.0 mm (depends on target material) |

| Sensitivity | 7.87 V/mm ±5% |

| Frequency Response | 0 to 10 kHz (typical) |

| Operating Temperature | –35 °C to +177 °C |

| Probe Material | Hermetically sealed stainless steel |

| Insulation Resistance | >10 MΩ at 500 VDC |

| Power Requirement | Requires compatible Bently Nevada proximitor |

| Connector Type | Standard Bently Nevada miniature coaxial |

| Mounting Thread | M10 × 1.0 or 3/8-24 UNF (depending on configuration) |

| Compliance | CE, RoHS, and ATEX certified for hazardous areas |

Applications

The 330905-00-05-50-02-00 probe is used in industries where precise vibration and shaft position monitoring is critical, particularly when long cable runs are necessary:

-

Steam and Gas Turbines – Continuous monitoring of shaft displacement and vibration to prevent misalignment or imbalance.

-

Compressors and Pumps – Early detection of bearing wear, mechanical looseness, and cavitation.

-

Motors and Generators – Accurate tracking of rotor dynamics for predictive maintenance programs.

-

Gearboxes and Industrial Fans – Detects gear mesh irregularities and mechanical looseness.

-

OEM Machinery – Provides reliable measurements in large installations or machinery with restricted monitoring access.

Advantages

-

High Accuracy and Reliability – Advanced eddy-current sensing ensures precise measurements under varying temperature and environmental conditions.

-

Long Cable Capability – 5-meter integral cable maintains signal integrity for remote installation points.

-

Compact NSv Design – Narrow Side View allows installation in tight spaces without affecting measurement accuracy.

-

Rugged Construction – Stainless steel housing and hermetic sealing provide protection against dust, moisture, and corrosive environments.

-

Seamless System Integration – Compatible with Bently Nevada 3300 series monitoring systems for straightforward installation and calibration.

-

Low Maintenance – Non-contact operation reduces wear and eliminates the need for frequent servicing.

FAQ

-

Which target material is optimal for calibration?

Factory calibration is performed for AISI 4140 steel; other ferromagnetic materials may require system recalibration. -

What is the maximum cable extension supported beyond 5 meters?

Extensions up to 9 meters are supported with a compatible Bently Nevada proximitor and extension cable. -

Is the probe suitable for hazardous or explosive environments?

Yes, it meets ATEX and CE Zone 1 requirements when installed with certified accessories. -

How is measurement accuracy affected by temperature changes?

The probe includes temperature compensation to minimize drift across the operating temperature range. -

What is the typical output from the probe when connected to a proximitor?

Standard output is 200 mV per mil (7.87 V/mm) with ±5% tolerance. -

Does the probe provide both dynamic vibration and static shaft position measurements?

Yes, it simultaneously delivers vibration and position signals. -

What is the minimum recommended cable bend radius during installation?

A minimum bend radius of 25 mm is recommended to maintain cable integrity. -

Is periodic recalibration required?

Calibration is generally only needed after major system reconfiguration or replacement of components. -

Is the probe shielded against electromagnetic interference (EMI)?

Yes, coaxial cable construction and internal shielding ensure excellent EMI resistance. -

Can this probe be used with older Bently Nevada monitoring systems?

Yes, when the correct proximitor and calibration procedures are applied, it is compatible with earlier systems.

Related Models in the Same Series

| Model | Description |

|---|---|

| 330904-08-15-10-02-05 | 3300 NSv probe, 1 m cable length |

| 330904-00-10-10-01-05 | Standard NSv probe with 1 m cable |

| 330905-00-05-50-02-00 | Long cable NSv probe, 5 m integral cable |

| 330904-05-14-05-02-00 | NSv probe with 0.5 m cable length |

| 330909-00-05-05-02-00 | High-temperature NSv probe |

| 330930-040-01-00 | Extended linear range NSv probe for larger shafts |

Popular Bently Nevada Models

| Model | Application |

|---|---|

| 3500/22M | Rack Interface Module for advanced machine monitoring |

| 330105-02-12-10-02-00 | Standard proximity probe for general industrial use |

| 330400 | High-performance accelerometer for vibration detection |

| 330500 | Velocity transducer for rotating equipment |

| 330780-91-05 | Proximitor sensor for precision displacement monitoring |

| 3500/42M | Advanced vibration monitor with diagnostics |

Excellent PLC

Excellent PLC