| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

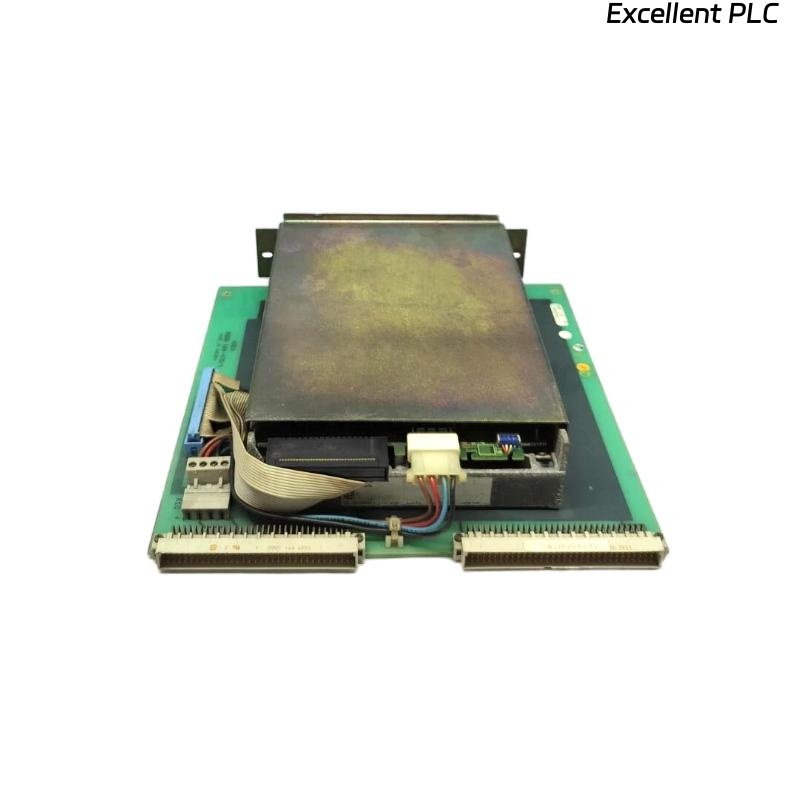

The ABB 3HAC032695-001 is a high-precision servo drive module developed for use in ABB’s industrial robotics platforms, particularly within the IRC5 controller system. Engineered to provide reliable power regulation and real-time motion control, this drive module is typically utilized in robotic arm applications across automotive, electronics, and material handling industries. With its robust performance in dynamic environments and integration with fieldbus protocols, the 3HAC032695-001 contributes significantly to ABB’s automation reliability and precision motion control.

Product Advantages

-

Optimized for ABB Robotics: Specifically designed for compatibility with ABB robot controllers, ensuring seamless integration.

-

Compact Form Factor: Saves space within the control cabinet, suitable for both retrofits and new installations.

-

High Efficiency Power Output: Provides precise control of servo motors with efficient energy use.

-

Durable and Long-Lasting: Built with industrial-grade components designed for 24/7 operation in demanding conditions.

-

Field Proven: Extensively tested and proven in industrial environments for stable and safe operation.

-

Maintenance Friendly: Modular design makes it easy to replace or upgrade with minimal downtime.

Technical Specifications

| Parameter | Value |

|---|---|

| Product Code | 3HAC032695-001 |

| Product Type | Servo Drive Module |

| Compatible Systems | ABB IRC5, IRB Series |

| Input Voltage | 24 VDC (control), 230–480 VAC (power) |

| Output Type | PWM-controlled, servo motor output |

| Communication Protocols | CAN, DeviceNet, PROFIBUS, Ethernet/IP |

| Cooling Method | Air-cooled |

| Operating Temperature | 0°C to +45°C |

| Storage Temperature | -25°C to +70°C |

| Cable length | 7 m |

| Weight | 3.56kg |

| Mounting Style | Panel-mounted with screw fixation |

| Certification | CE, UL, RoHS compliant |

Product Applications

-

Industrial Robotics: Drives servo motors in articulated robots for precise joint movements.

-

Automotive Manufacturing: Used in robotic arms for welding, painting, and assembly tasks.

-

Food and Beverage Processing: Supports hygienic robotic operations in packaging and material transfer.

-

Electronics Assembly: Enables micrometer-level accuracy in pick-and-place applications.

-

Logistics Automation: Integrated into robotic systems for palletizing, sorting, and order fulfillment.

-

Metalworking: Powers robots performing laser cutting, grinding, or welding in production lines.

Installation Guidelines

-

Ensure power is disconnected before handling the module.

-

Mount the servo drive onto a flat control panel using designated screw holes.

-

Verify grounding and shielding of all connected servo motors.

-

Connect input power cables to specified terminals according to the wiring diagram.

-

Configure the communication interface via DIP switch or software (if applicable).

-

Perform a test run with limited speed before putting into full operation.

10 Frequently Asked Questions (FAQs)

Q1: What robot models is this module compatible with?

A1: It is commonly used with ABB IRB series robots like IRB 6600, IRB 4400, and IRB 2400, within IRC5 controllers.

Q2: Can this module be repaired if damaged?

A2: Yes, provides authorized repair services, and third-party repair is also possible with original components.

Q3: Is firmware upgrade required?

A3: Only if paired with newer robot controller firmware. Otherwise, the default firmware is suitable for most applications.

Q4: How do I identify failure signals from this module?

A4: The module features status LEDs that indicate operating state and fault codes; detailed error mapping is provided in ABB’s technical manual.

Q5: Does it support Ethernet/IP?

A5: Yes, it supports various industrial fieldbus protocols, including Ethernet/IP.

Q6: What kind of motors can it drive?

A6: It is designed to drive ABB brushless servo motors used in robotic arms.

Q7: Is this module hot-swappable?

A7: No, it must be powered down before removal or replacement to avoid damage.

Q8: Can it be used in high-humidity environments?

A8: It must be installed in a sealed control cabinet with humidity control if used in such environments.

Q9: What maintenance is required?

A9: Periodic dust removal and inspection of connector integrity are recommended every 6–12 months.

Q10: Are software tools required for configuration?

A10: Yes, ABB’s RobotStudio or other drive configuration tools are used to set parameters and test the system.

Recommended Models (Same Series or Related)

-

ABB 3HAC14551-2

-

ABB 3HAC025338-001

-

ABB 3HAC16831-1

-

ABB 3HAC14549-4

-

ABB 3HAC020466-001

-

ABB 3HAC029157-001

Popular Models from the Same Brand

| Model Number | Description | Voltage | Dimensions (mm) | Weight |

|---|---|---|---|---|

| 3HAC025338-001 | Drive Unit for IRB robots | 480V | 270×190×90 | 3.6 kg |

| 3HAC14551-2 | Servo Motor Controller | 230-480V | 250×180×85 | 3.2 kg |

| 3HAC16831-1 | Compact Servo Drive | 230V | 240×170×70 | 2.9 kg |

| 3HAC14549-4 | Motion Control Module | 24 VDC | 210×140×60 | 2.5 kg |

| 3HAC020466-001 | Teach Pendant Interface | 24 VDC | 300×200×70 | 1.8 kg |

| 3HAC050363-001 | Power Supply Module | 480V | 280×185×80 | 3.5 kg |

| DSQC679 | Main Drive Control Board | 24 VDC | 200×150×50 | 1.5 kg |

| DSQC679B | Updated Drive Controller | 24 VDC | 205×155×55 | 1.6 kg |

Excellent PLC

Excellent PLC