| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

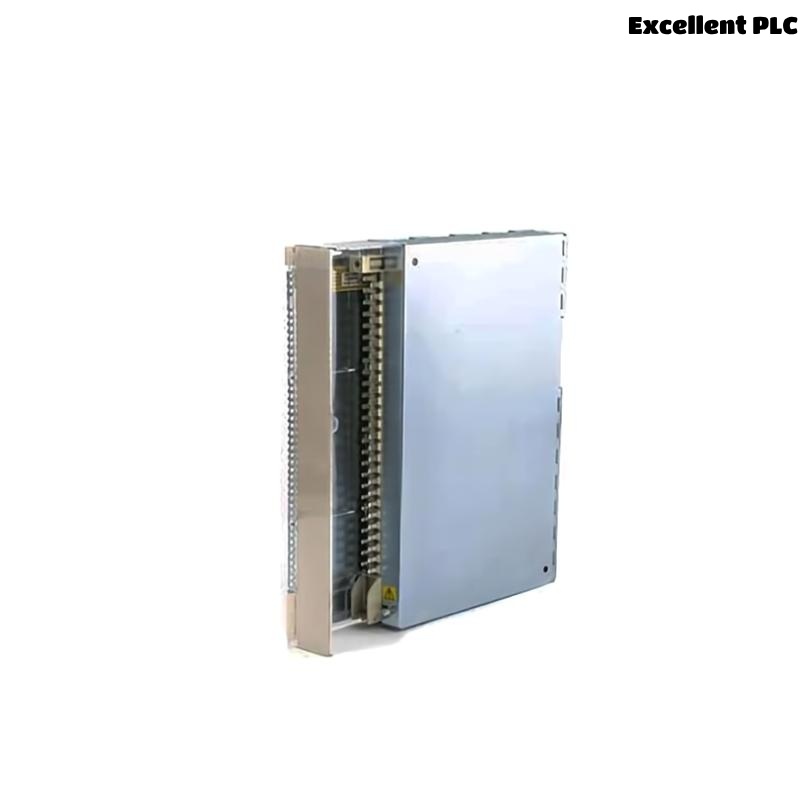

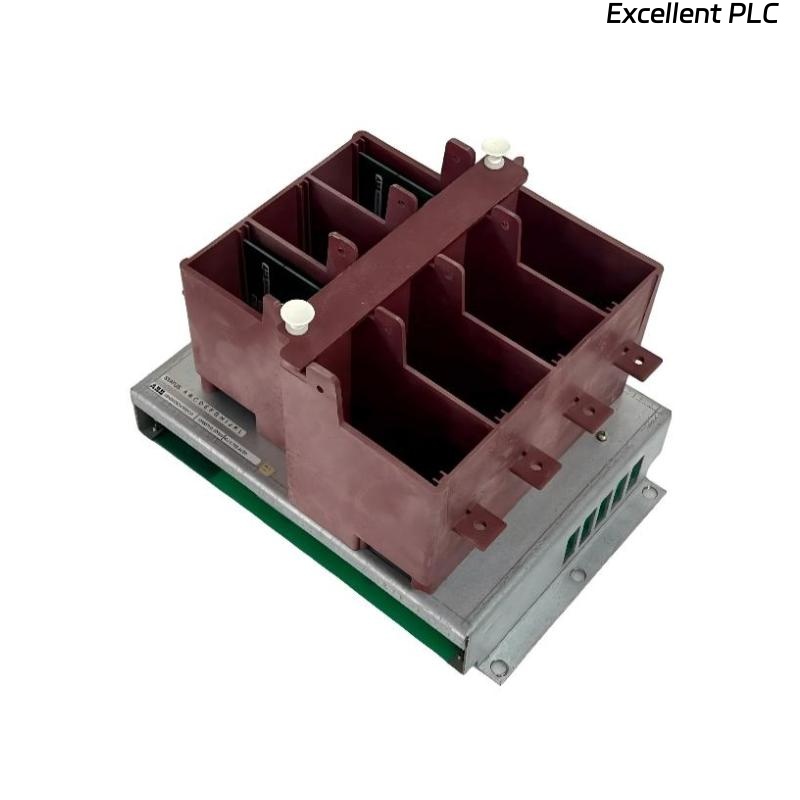

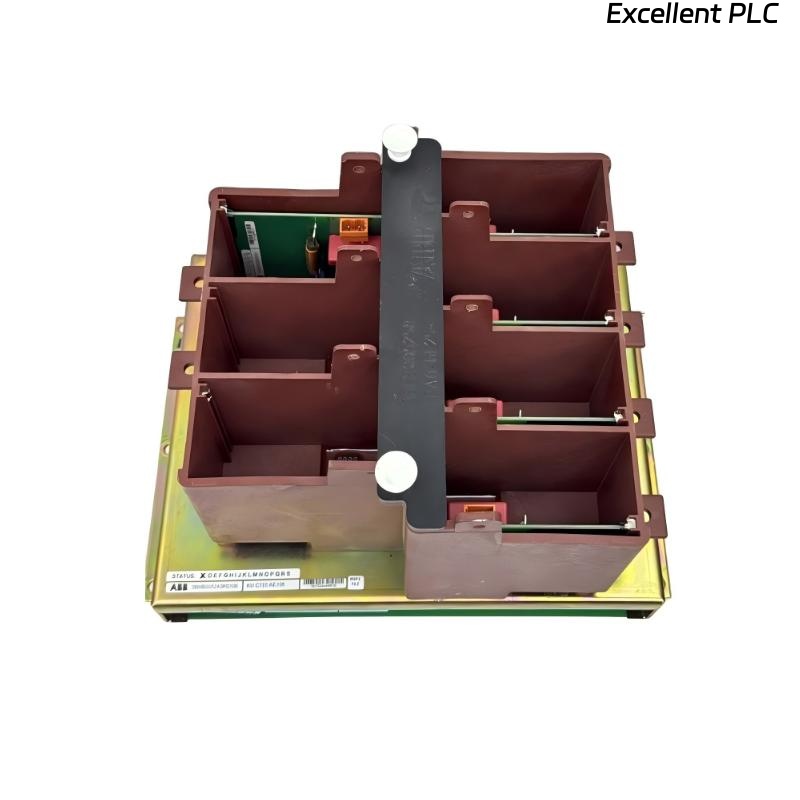

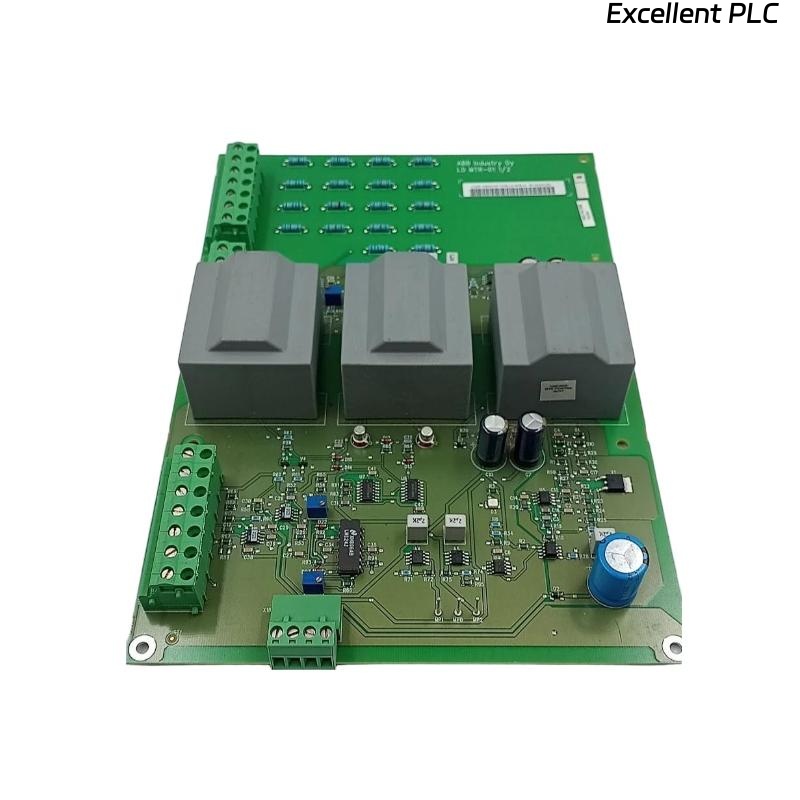

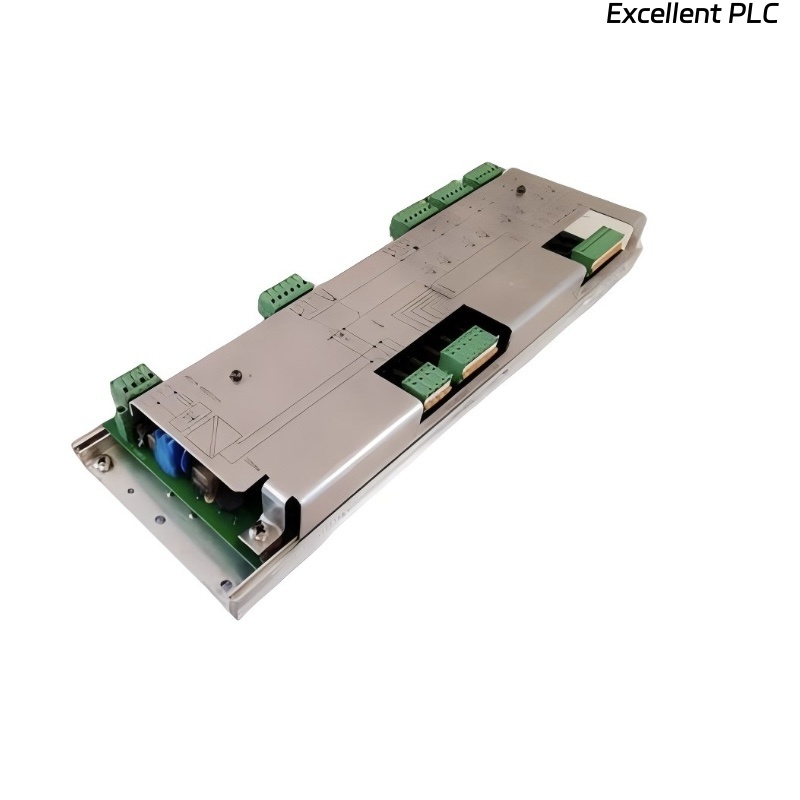

The ABB AO610 3BSE018184R1 Analog Output Module is a reliable and precise module designed for use within ABB’s S800 I/O system. It is engineered to provide high-quality analog current outputs, making it suitable for various industrial automation and control applications.

This module offers 8 individual analog output channels, each capable of delivering a 4-20 mA current signal. It supports galvanic isolation between outputs and system electronics to ensure robust signal integrity and protect against electrical interference. The AO610 is built to meet the stringent requirements of process control environments, where accuracy and reliability are paramount.

The module is well-suited for industries requiring stable analog output signals for controlling valves, actuators, and other field devices in applications like power generation, water treatment, and chemical processing.

Product Specifications

| Parameter | Details |

|---|---|

| Model | AO610 |

| ABB Product Code | 3BSE018184R1 |

| Module Type | Analog Output Module |

| Number of Outputs | 8 Channels |

| Output Signal | 4-20 mA Current Signal |

| Resolution | 12-bit Digital-to-Analog Conversion |

| Output Isolation | Galvanic Isolation between Channels and System |

| Max Load Resistance | 600 Ω |

| Output Accuracy | ±0.1% of Full Scale |

| Power Supply | Supplied via S800 Backplane |

| Operating Temperature | 0°C to +60°C |

| Storage Temperature | -40°C to +85°C |

| Response Time | Less than 1 millisecond per channel |

| Mounting | DIN Rail / Backplane mounting |

| Dimensions (W x H x D) | 120 x 100 x 50 mm |

| Weight | 0.5 kg |

| Certifications | CE, UL, CSA, RoHS Compliant |

| Communication | Connection through S800 I/O bus |

Applications

The ABB AO610 module finds its place in a broad spectrum of industrial automation environments, especially where high accuracy and reliability in analog output are required. Typical application sectors include:

-

Power Plants: For controlling turbine valves, generator excitation systems, and regulating fuel supply.

-

Water & Wastewater Treatment: Controlling dosing pumps, valve actuators, and chemical feed systems.

-

Oil & Gas: Pipeline control, refinery operations, and wellhead automation.

-

Chemical Industry: Precise control of reactors, flow controllers, and process valves.

-

Pulp & Paper Mills: Regulating machine speeds, moisture control systems, and chemical dosing.

-

Metallurgical Industry: Furnace control, cooling system regulation, and process automation.

Product Advantages

-

High Signal Precision: Offers stable and highly accurate analog outputs critical for closed-loop control.

-

Galvanic Isolation: Protects the system from electrical noise and cross-channel interference.

-

Fast Response Time: Supports quick signal updates, enabling dynamic process control.

-

Compact and Modular Design: Easily mounts onto DIN rails or backplanes, saving space and simplifying system upgrades.

-

Robust Build Quality: Designed to withstand harsh industrial environments and comply with international standards.

-

Easy Integration: Seamlessly fits into ABB’s S800 I/O architecture, supporting straightforward installation and configuration.

-

Diagnostic Capabilities: Monitors output channel health to facilitate preventative maintenance and reduce downtime.

-

Long-Term Availability: Supported as part of ABB’s mature and proven automation product line.

Frequently Asked Questions (FAQ)

-

What kind of analog output does the AO610 provide?

The module provides 8 channels of analog current output, each delivering 4-20 mA signals. -

Is the AO610 module isolated?

Yes, each channel is galvanically isolated from others and from the system. -

What is the maximum load resistance for each output?

Each channel can drive loads up to 600 ohms. -

What environments is the AO610 suitable for?

It is suitable for industrial environments with operating temperatures from 0°C to 60°C. -

What is the response time of the AO610?

The response time is less than 1 millisecond per output channel. -

How is the AO610 powered?

It receives power via the S800 backplane it is mounted on. -

Can this module be hot-swapped?

Hot swapping depends on the overall system design; it’s generally recommended to follow ABB’s system procedures. -

What are the typical uses of the AO610?

Controlling valves, pumps, actuators, and other analog-controlled devices in process automation. -

Does the AO610 support diagnostics?

Yes, it can detect wiring faults like shorts and open circuits. -

What systems is the AO610 compatible with?

It is designed for ABB’s S800 I/O system and integrates with ABB’s distributed control systems.

Related Models from the Same or Compatible Series

| Model | Description | Signal Type | Channels | Compatibility |

|---|---|---|---|---|

| AI810 (3BSE008516R1) | Analog Input Module | Analog Input | 8 | ABB S800 I/O |

| AO810 (3BSE008522R1) | Analog Output Module | Analog Output | 8 | ABB S800 I/O |

| DI810 (3BSE008524R1) | Digital Input Module | Digital Input | 16 | ABB S800 I/O |

| DO810 (3BSE008525R1) | Digital Output Module | Digital Output | 16 | ABB S800 I/O |

| AI830 (3BSE008540R1) | High Density Analog Input Module | Analog Input | 16 | ABB S800 I/O |

| AO830 (3BSE008541R1) | High Density Analog Output Module | Analog Output | 16 | ABB S800 I/O |

Popular ABB Models (Same Brand)

| Model | Description | Category | Application |

|---|---|---|---|

| PM864AK01 | AC 800M CPU | PLC Controller | Distributed Control |

| CI854AK01 | PROFIBUS DP Module | Communication Module | Fieldbus Integration |

| AI810 | Analog Input Module | Analog Input Module | Process Monitoring |

| AO810 | Analog Output Module | Analog Output Module | Field Device Control |

| PM856K01 | High Performance CPU | PLC Controller | Complex Automation |

| AC800M HI | Safety PLC | Safety Controller | SIL Certified Applications |

Excellent PLC

Excellent PLC