| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

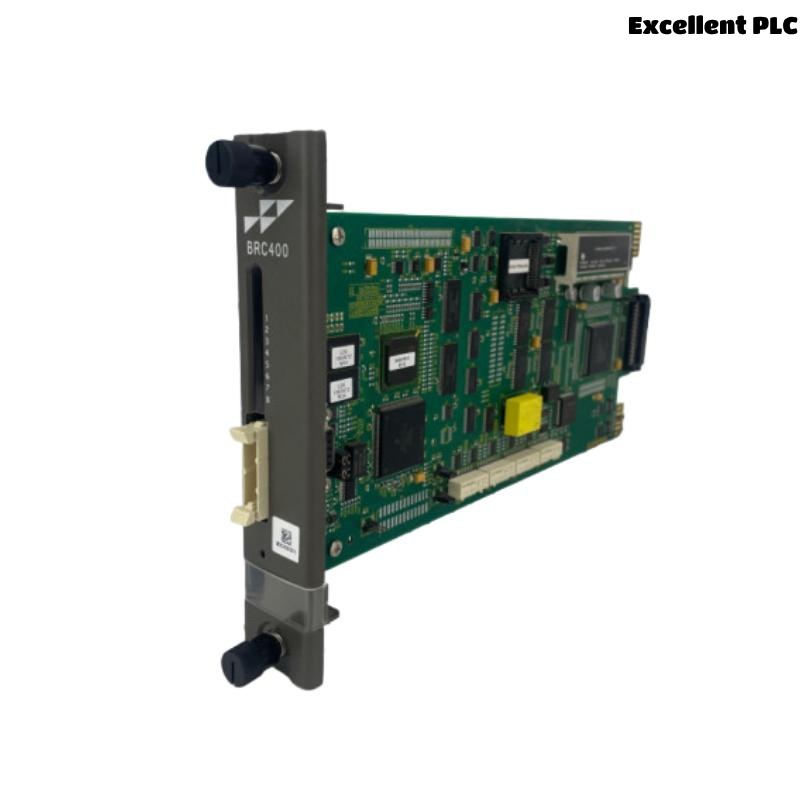

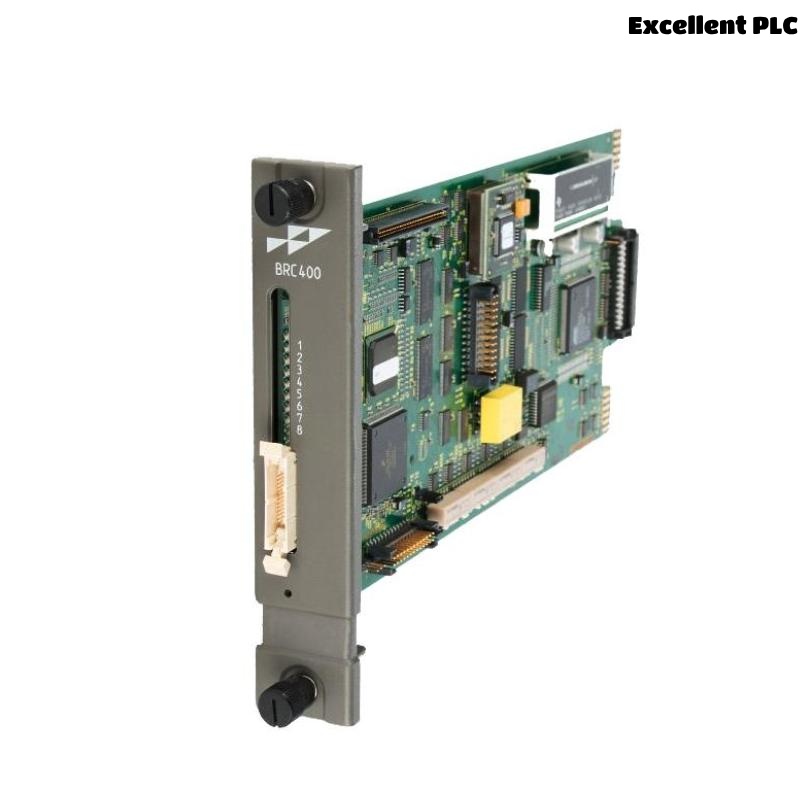

ABB Bailey BRC400 Product Introduction

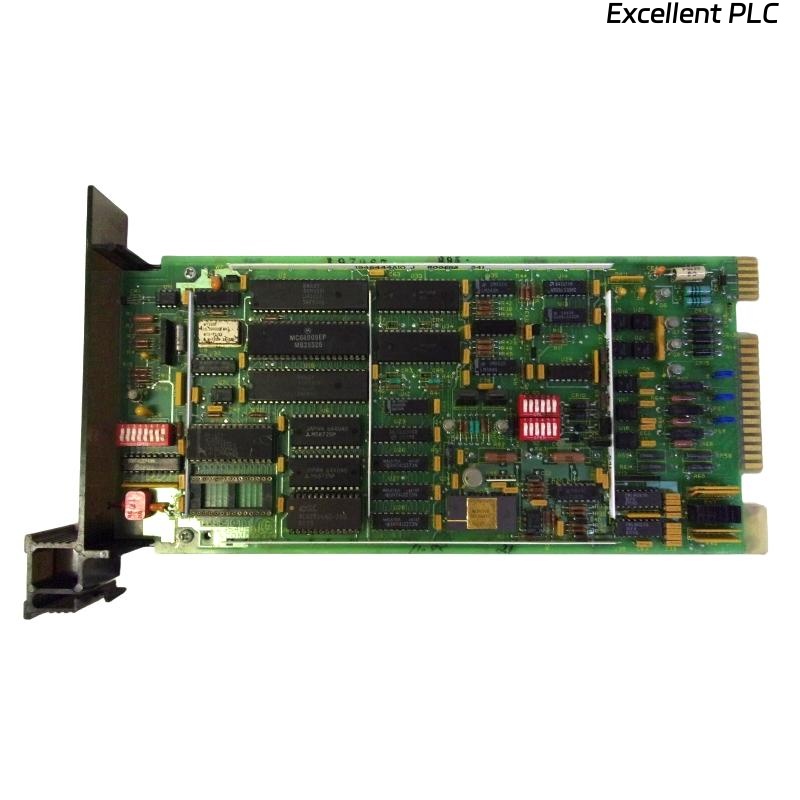

The ABB Bailey BRC400 is a highly respected and widely used controller within the INFI 90 distributed control system family, designed to deliver reliable process control in demanding industrial environments. It stands out with its robust build, advanced processing capabilities, and flexibility that allows seamless integration into new or existing ABB Bailey systems.

At its core, the BRC400 functions as the primary processing unit that manages complex process control tasks, communications, and I/O processing. It incorporates fault-tolerant architecture and powerful computing resources, ensuring accurate, real-time decision-making and maintaining operational stability across continuous and batch processes.

Due to its proven performance and adaptability, the BRC400 has become a backbone controller in industries such as power generation, chemical processing, oil and gas, pulp and paper, and water treatment. Its design focuses on long-term reliability and ease of maintenance, making it a trusted choice for critical control applications worldwide.

Technical Parameters

| Parameter | Details |

|---|---|

| Model | ABB Bailey BRC400 |

| Processor | High-speed 32-bit processor |

| Memory | 8 MB DRAM, 1 MB Flash |

| Communication | INFI-NET, Plant Loop, Serial ports |

| Operating Temperature | 0°C to +60°C |

| Storage Temperature | -40°C to +85°C |

| Power Supply | 5V DC, internal regulation |

| Dimensions | 265 x 187 x 25 mm |

| Weight | 0.95 kg |

| Mounting | Rack-mounted or panel-mounted |

| Housing Material | Industrial-grade reinforced plastic & metal shielding |

| Compliance | CE, UL, RoHS |

Product Applications

The ABB Bailey BRC400 controller is applied across a wide range of industrial sectors due to its excellent reliability and flexibility. It plays an essential role in:

-

Large-scale power plants, where it manages turbine, boiler, and balance-of-plant controls.

-

Chemical and petrochemical processing plants, handling reactor, distillation, and material transfer systems.

-

Oil and gas production, refining, and distribution, controlling critical safety and production systems.

-

Pulp and paper mills, managing continuous and batch processes to ensure consistent quality.

-

Water and wastewater treatment facilities, automating complex filtration, chemical dosing, and distribution.

-

Any process industry requiring high-speed control, data acquisition, and integration with SCADA or MES systems.

The BRC400 is highly adaptable, making it suitable for both greenfield projects and retrofits in older systems that require modern control technology.

Product Advantages

-

Proven Reliability: Decades of field-proven stability in harsh industrial environments.

-

Real-time Processing: Advanced computing power to handle large process data volumes with minimal latency.

-

Flexible Networking: Seamless integration with existing ABB Bailey INFI 90 systems and modern networks.

-

Expandable Memory: Sufficient capacity to store large control strategies and process data.

-

Robust Build: Designed with durable materials and industrial-grade components for long service life.

-

Easy Maintenance: Modular design allows quick replacement and upgrades without system downtime.

-

Comprehensive Diagnostics: Built-in tools for real-time monitoring and troubleshooting.

-

Compatibility: Supports a wide range of ABB I/O modules, operator stations, and engineering tools.

-

Reduced Downtime: Fault-tolerant architecture and hot-swappable components.

-

Global Support: Backed by ABB’s worldwide service and spare parts network.

FAQs (10 detailed, natural answers)

Q1: What makes the BRC400 unique among industrial controllers?

A1: Its balance of high-speed real-time processing, fault-tolerant design, and robust compatibility with ABB INFI 90 systems make it especially reliable in mission-critical applications.

Q2: Can the BRC400 integrate with modern SCADA systems?

A2: Yes. Thanks to its versatile communication options, it can connect to SCADA, HMI, and MES systems through INFI-NET and other standard protocols.

Q3: How is the BRC400 typically mounted?

A3: The controller is usually rack-mounted in ABB cabinets, but it can also be panel-mounted depending on site design and engineering preferences.

Q4: What industries most commonly use the BRC400?

A4: Power generation, oil & gas, chemicals, pulp & paper, and water treatment are the leading sectors due to the need for stable and continuous process control.

Q5: What is the typical lifecycle of a BRC400 controller?

A5: With proper maintenance, it can easily operate for over 5 years, supported by ABB’s long-term spare parts availability and service programs.

Q6: Is the BRC400 compatible with modern ABB software?

A6: Yes, it works seamlessly with ABB’s engineering tools, diagnostic tools, and operator interface software within the INFI 90 family.

Q7: What kind of power supply does it require?

A7: The BRC400 runs on a regulated internal 5V DC power supply, usually sourced from a larger industrial power distribution unit.

Q8: How much memory does it include?

A8: It features 8 MB DRAM for process data and 1 MB Flash for firmware and control strategies.

Q9: Is it easy to upgrade or replace modules?

A9: Yes. Its modular architecture and hot-swappable design allow engineers to upgrade firmware or replace faulty modules without full system shutdown.

Q10: Does the BRC400 comply with safety standards?

A10: Absolutely. It meets CE, UL, and RoHS requirements, ensuring it adheres to strict industrial safety and environmental standards.

Recommended 6 Same-Series or Related Models

-

ABB Bailey BRC410 – Enhanced memory and speed version.

-

ABB Bailey BRC300 – Earlier generation for legacy systems.

-

ABB Bailey IMMFC03 – Multi-function controller module for complex control strategies.

-

ABB Bailey IMDSI02 – Digital input module for data acquisition.

-

ABB Bailey INNIS01 – Network interface module to expand communication.

-

ABB Bailey IMCPM02 – Control processor module supporting additional redundancy.

6 Popular ABB Models (with specs in table)

| Model | Function | Dimensions (mm) | Weight (kg) | Power Supply |

|---|---|---|---|---|

| AI931 | Analog input module | 100×120×30 | 0.25 | 24V DC |

| BRC410 | Advanced process controller | 280×240×60 | 2.2 | 5V DC |

| IMMFC03 | Multi-function controller | 280×240×60 | 2.0 | 5V DC |

| IMDSI02 | Digital input interface | 100×120×30 | 0.3 | 24V DC |

| IMDSO14 | Digital output interface | 100×120×30 | 0.3 | 24V DC |

| IMCPM02 | Central processor module | 280×240×60 | 2.1 | 5V DC |

Excellent PLC

Excellent PLC