| Company Information | ||||||||

| sales@xmjzjsgs.com | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

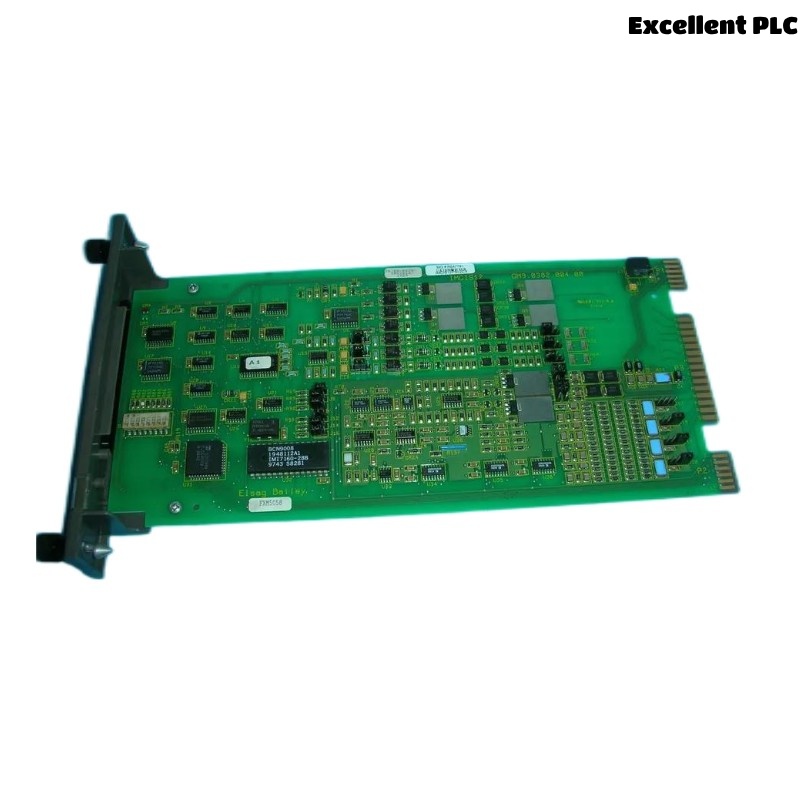

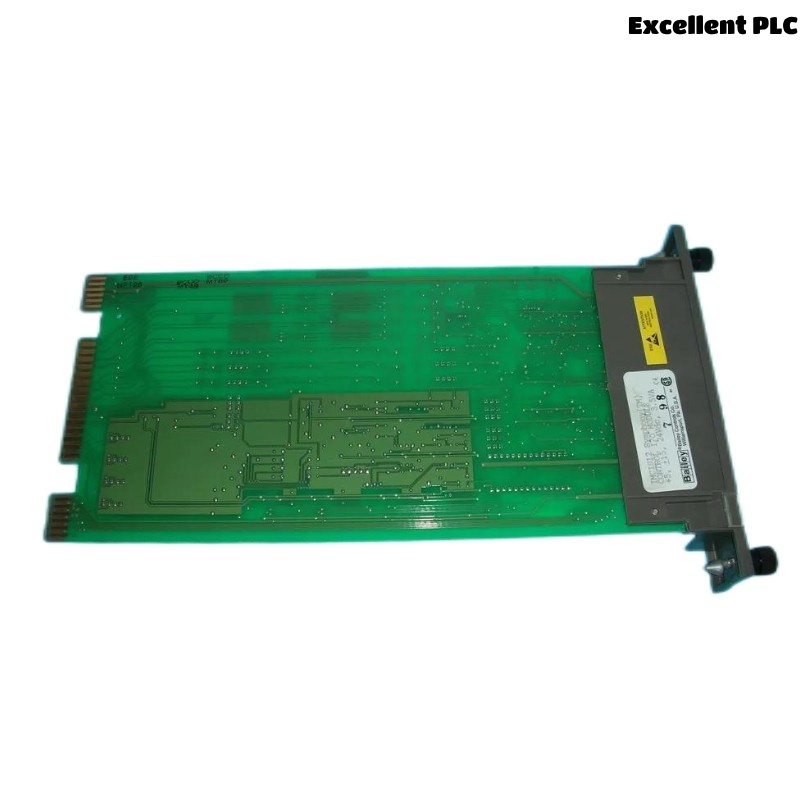

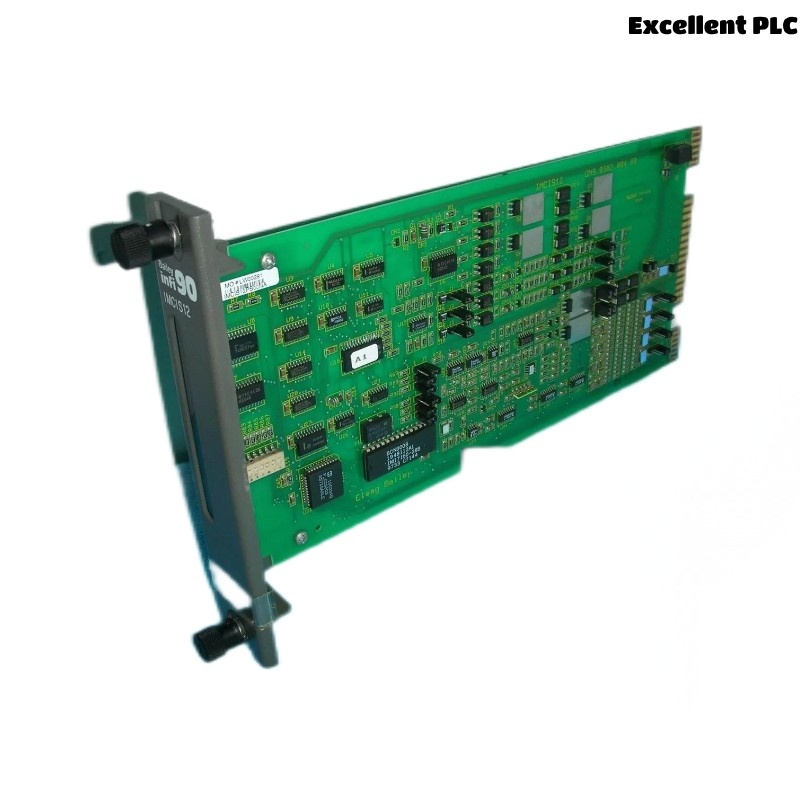

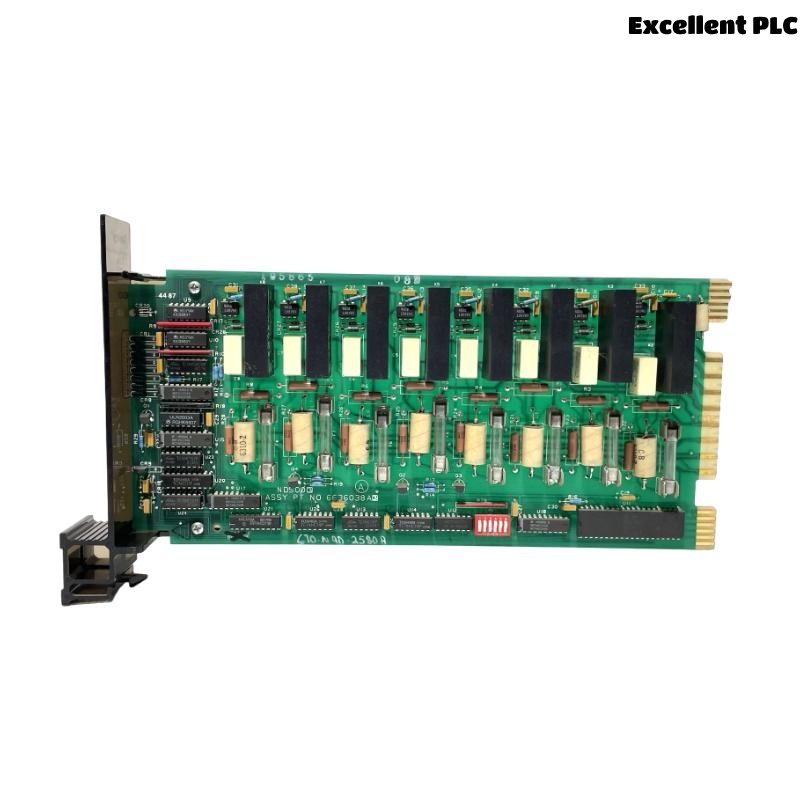

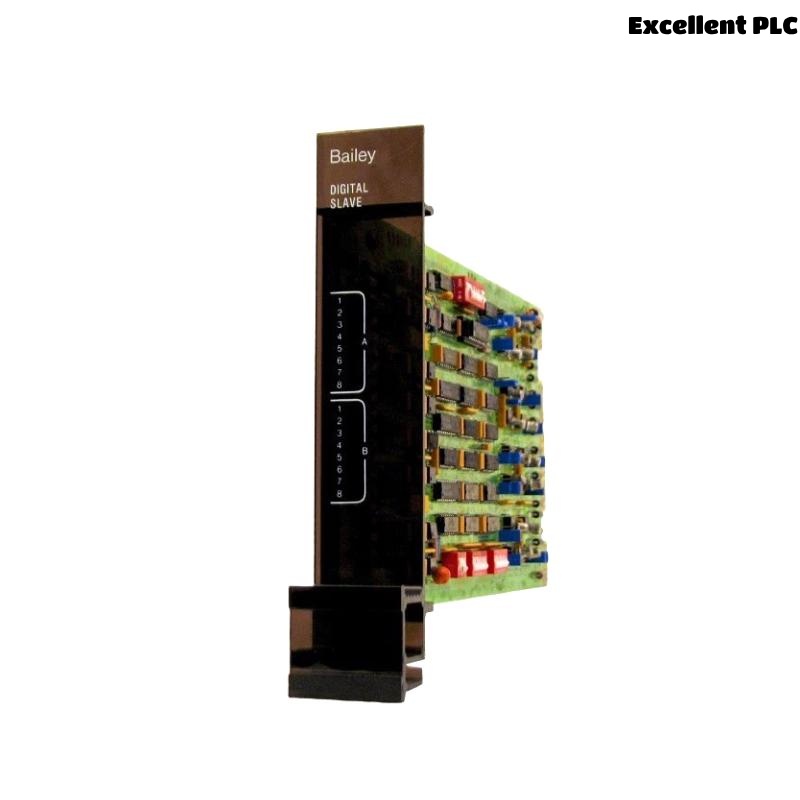

Product Overview

The ABB Bailey IMCIS12 Controlling I/O Slave Module is a high-performance, versatile input/output slave module designed for ABB’s INFI 90 and System 800xA automation systems. It provides flexible I/O capabilities for a wide range of industrial applications, enabling seamless communication between field devices and control systems. The IMCIS12 module acts as an interface for controlling and monitoring inputs and outputs in real-time, offering significant advantages in terms of system integration, scalability, and reliability.

The IMCIS12 is an ideal solution for industries that demand high availability, fast response times, and accurate control, such as chemical processing, power generation, oil & gas, and water treatment. This module is engineered to support a variety of signal types, providing analog, digital, and relay outputs, as well as input configurations, enabling the control and monitoring of diverse process variables such as temperature, pressure, flow, and level. With built-in diagnostics and robust protection mechanisms, the IMCIS12 ensures reliable operation in harsh industrial environments.

Key Features

-

Flexible I/O Options: Supports a variety of input and output types, including analog inputs, digital inputs, relay outputs, and digital outputs, offering broad compatibility with different field devices.

-

Real-Time Control: Provides real-time monitoring and control of industrial processes with high-speed data exchange and low-latency response.

-

Advanced Diagnostics: Integrated diagnostic features ensure continuous monitoring of the module and the connected devices, minimizing downtime and preventing process interruptions.

-

Modular Design: Can be easily integrated into Bailey INFI 90 or System 800xA platforms, offering modular flexibility for system expansion.

-

High Environmental Tolerance: Built to operate in challenging industrial environments, with a wide operating temperature range and IP20 protection.

-

Galvanic Isolation: Offers galvanic isolation for protection against electrical interference and surges, ensuring stable signal transmission.

-

Scalability: Ideal for large-scale automation projects due to its modular design, enabling easy expansion and integration into existing systems.

-

Compact and Efficient: Space-efficient design allows for easy mounting in control panels with limited space.

Technical Specifications

| Parameter | Specification |

|---|---|

| Model Number | IMCIS12 |

| Part Number | 3BSE040409R1 |

| Function | Controlling I/O Slave Module |

| Input Types | 4-20 mA, 0-10 V, 0-20 mA, Digital Inputs |

| Output Types | Relay Outputs, Digital Outputs, 4-20 mA, 0-10 V |

| Channels | 12 I/O channels (8 analog, 4 digital) |

| Resolution | 12-bit |

| Accuracy | ±0.1% of full scale |

| Power Supply | 24 VDC (nominal) |

| Power Consumption | Approx. 3 W |

| Operating Temperature | -20°C to 60°C (-4°F to 140°F) |

| Storage Temperature | -40°C to 85°C (-40°F to 185°F) |

| Dimensions | 178 x 51 x 330mm |

| Weight | 0.2 kg |

| Mounting | DIN rail mountable |

| Environmental Protection | IP20, suitable for indoor use |

| Compliance | CE, UL, RoHS |

Industry Applications

The ABB Bailey IMCIS12 Controlling I/O Slave Module is widely used in industries that require precise and reliable control and monitoring of various process variables:

-

Chemical Processing: Facilitates the monitoring and control of chemical reactions, flow rates, and pressure levels in chemical plants.

-

Power Generation: Used in power plants for real-time control of temperature, pressure, and flow in turbines, boilers, and reactors.

-

Oil & Gas: Key in drilling and refining operations, where continuous monitoring of pressure, temperature, and flow is crucial for safe and efficient operations.

-

Water Treatment: Utilized in water purification and distribution systems to monitor and control water quality, pressure, and flow rates.

-

Food & Beverage: Helps ensure consistency and quality in production processes, including temperature, pressure, and flow control.

-

Pharmaceuticals: Provides control over critical manufacturing processes, ensuring product quality and compliance with industry standards.

-

Metals and Mining: Used in the control of high-temperature furnaces, smelting processes, and material handling systems.

Product Advantages

-

Versatile I/O Configuration: The IMCIS12 module supports a variety of input and output types, making it ideal for controlling diverse process variables.

-

Modular and Scalable: Easily integrates into larger automation systems, allowing for modular expansion as needs grow.

-

High-Speed Control: With real-time data exchange, the IMCIS12 ensures fast response times, making it suitable for fast-paced industrial applications.

-

Comprehensive Diagnostics: Continuous diagnostics minimize system downtime and allow for proactive maintenance.

-

Protection Against Electrical Interference: Galvanic isolation ensures reliable operation even in environments with high electrical noise or surges.

-

Space-Saving Design: Compact design makes it ideal for installations with limited panel space.

Frequently Asked Questions (FAQ)

-

Q: What is the IMCIS12 module used for?

A: The IMCIS12 module is used for controlling and monitoring I/O in industrial automation systems, providing precise control of inputs and outputs. -

Q: How many channels does the IMCIS12 support?

A: The IMCIS12 supports 12 I/O channels, with 8 analog inputs and 4 digital inputs/outputs. -

Q: What is the input signal range for the IMCIS12?

A: The module supports 4-20 mA, 0-10 V, and 0-20 mA input signals, along with digital inputs. -

Q: What output signals does the IMCIS12 support?

A: The IMCIS12 provides relay outputs, digital outputs, and analog outputs (4-20 mA, 0-10 V). -

Q: Can the IMCIS12 module be used in hazardous environments?

A: The IMCIS12 is designed for general industrial environments but is not intrinsically safe for hazardous locations. -

Q: What is the accuracy of the IMCIS12 module?

A: The IMC12 has an accuracy of ±0.1% of full scale. -

Q: What is the operating temperature range of the IMCIS12?

A: The module operates in temperatures ranging from -20°C to 60°C (-4°F to 140°F). -

Q: How is the IMCIS12 mounted?

A: The module can be mounted on a DIN rail, making installation simple and flexible. -

Q: What type of diagnostics are available with the IMCIS12?

A: The IMCIS12 includes advanced diagnostics that monitor the health of the module and connected field devices, alerting operators to potential issues. -

Q: How is the power supply for the IMCIS12 configured?

A: The IMCIS12 requires a 24 VDC power supply and consumes approximately 3 W of power.

Recommended Related Models

| Model | Description |

|---|---|

| IMCIS11 | 8-Channel Controlling I/O Slave Module |

| IMASI12 | Analog Input Slave Module for Bailey INFI 90 |

| IMDO12 | Digital Output Module for System 800xA |

| IMAO13 | Analog Output Module for Process Control |

| IMCIO11 | Mixed Input/Output Slave Module |

| IMCSO12 | Signal Conditioning Module |

Popular ABB Modules (Same Brand)

| Model | Description |

|---|---|

| AI841 | High-Accuracy Analog Input Module |

| AO840 | Analog Output Module |

| DI830 | Digital Input Module |

| DO840 | Digital Output Module |

| AC800M | Process Automation Controller |

| CI860 | Communication Interface Module for Distributed Control |

Excellent PLC

Excellent PLC