| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

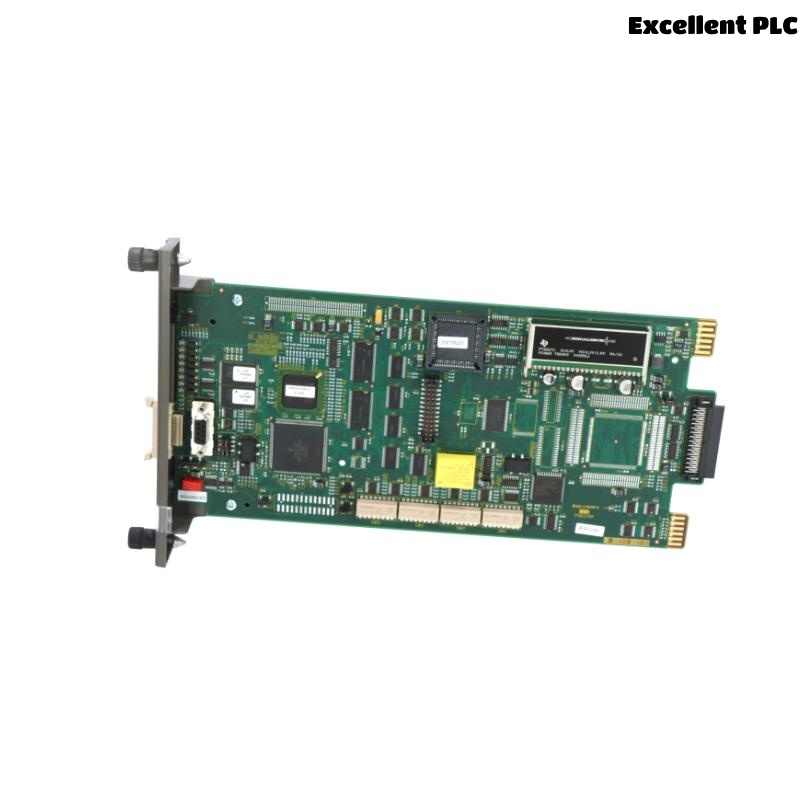

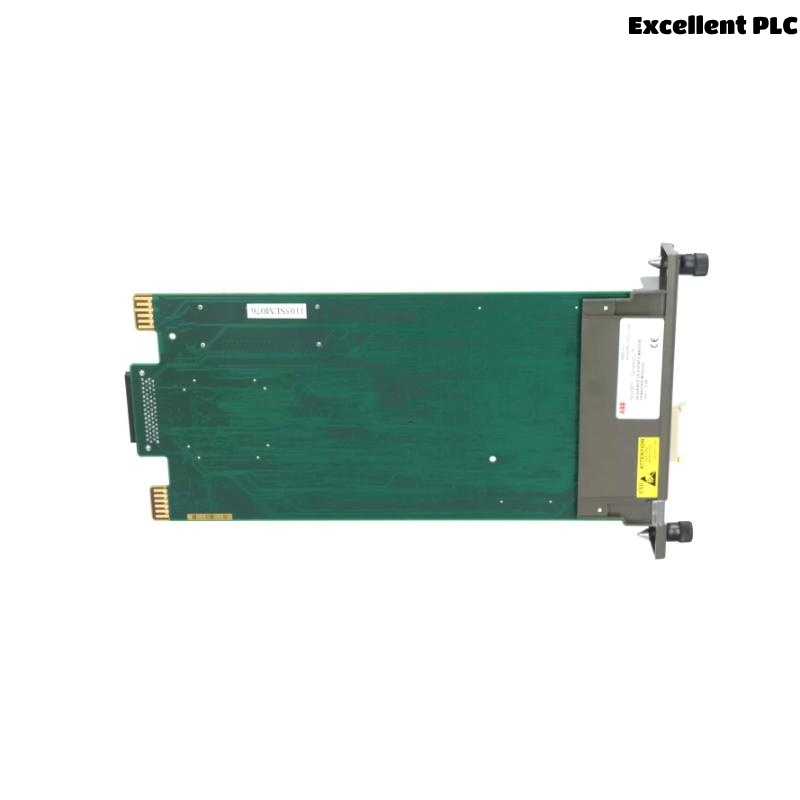

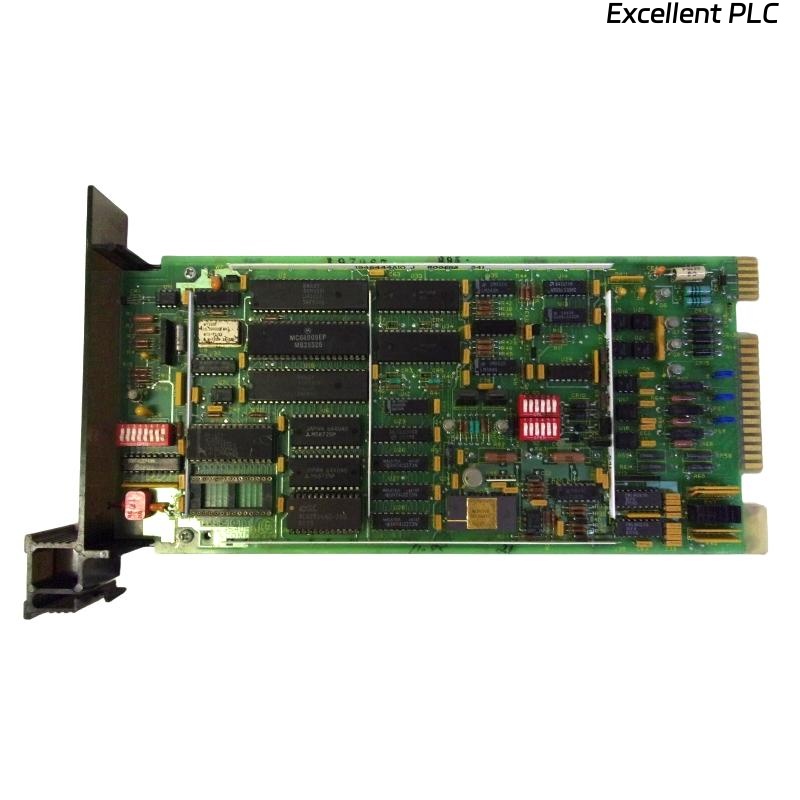

The ABB Bailey INSEM11 is a high-performance Sequence of Events (SOE) Master Module designed for critical event detection and timestamping in Distributed Control Systems (DCS). It plays a central role in capturing and organizing input events with millisecond resolution, making it ideal for post-event diagnostics, troubleshooting, and process optimization in industrial automation environments.

This module operates within ABB’s Infi 90 control system, working as the master controller that receives, organizes, and transmits time-critical events gathered from remote SOE slave modules. It significantly improves operational visibility by accurately logging status changes across systems and networks. This feature is particularly vital in high-stakes applications such as power generation, oil and gas, and process control plants.

Product Specifications

| Parameter | Specification |

|---|---|

| Model Number | INSEM11 |

| Module Type | Sequence of Events Master Module |

| Primary Function | Collects, timestamps, and transmits SOE data from connected slave modules |

| Supported Slave Modules | INSES01, INSES02, or equivalent SOE modules |

| Time Resolution | 1 millisecond accuracy |

| Communication Interface | Infi-Net protocol |

| Mounting Type | Module Rack (standard Bailey form factor) |

| Data Buffer Capacity | Up to 1024 events buffered |

| Event Synchronization | Synchronization with master system clock via DCS |

| Redundancy Support | Yes (hot-standby configurations possible) |

| Operating Temperature | 0°C to 60°C (32°F to 140°F) |

| Storage Temperature | -40°C to +85°C (-40°F to 185°F) |

| Power Supply Voltage | 5 VDC (supplied via backplane) |

| Power Consumption | 3.2 W (typical) |

| Dimensions (W x H x D) | 175 × 40 × 120 mm |

| Weight | 0.65 kg |

| Certifications | CE, RoHS, IEC industrial standards |

Product Applications

The INSEM11 Sequence of Events Master Module is deployed across various critical industries where real-time event monitoring and diagnosis are vital. Typical application domains include:

-

Power Generation Plants – Ensures prompt identification of generator trips, breaker operations, and protection relay actions.

-

Petrochemical Facilities – Tracks valve status, pressure alarms, and emergency shutdowns.

-

Water and Wastewater Systems – Monitors pump operations, control valve activity, and system alarms.

-

Manufacturing Plants – Detects machine-level fault occurrences and sensor triggers for diagnostic use.

-

Metallurgical Processing – Records safety-critical changes in high-temperature or pressurized environments.

-

SCADA Systems – Integrates seamlessly with SCADA interfaces for enhanced historical data logging.

Product Advantages

-

Precise Event Logging: Offers 1ms resolution for accurate tracking of fast-changing digital inputs.

-

Master-Slave Architecture: Centralizes data from multiple SOE input modules, ensuring data cohesion.

-

Seamless Integration: Fully compatible with ABB Bailey Infi 90 and Symphony control platforms.

-

Redundancy Support: Can be configured for redundant operation to ensure system availability.

-

Large Event Buffer: Temporarily stores events in memory to prevent data loss during high traffic.

-

Time Synchronization: Synchronizes with DCS time servers to maintain accurate logging.

-

Diagnostic Capability: Monitors module health and slave connectivity for proactive maintenance.

-

Compact Design: Fits within standard ABB module racks, ensuring easy replacement and maintenance.

-

Durability: Engineered to withstand industrial environmental conditions with robust construction.

-

Vendor Support: Long-term support available from ABB with global service presence.

Frequently Asked Questions (FAQ)

-

What is the main function of the INSEM11 module?

The INSEM11 collects and timestamps digital input events from slave modules to support post-event analysis. -

How accurate is the time-stamping?

It offers a resolution of 1 millisecond for high-precision event recording. -

Which slave modules can be used with INSEM11?

It is compatible with INSES01 and INSES02 Sequence of Events Slave Modules. -

Is this module hot-swappable?

No, it should be replaced only when the system is powered down. -

Can the module work in a redundant configuration?

Yes, it supports hot standby setups for redundancy. -

Does the module support integration with SCADA systems?

Yes, it can transmit logged events to SCADA/DCS platforms via the control network. -

What happens if the buffer is full during high-frequency events?

The module prioritizes event order but may overwrite oldest events if the buffer overflows. -

Is the INSEM11 suitable for safety-critical applications?

While it enhances diagnostics, it should be used alongside certified safety systems. -

How is time synchronization achieved?

Via DCS master clock synchronization or dedicated time servers. -

Can the INSEM11 record analog inputs?

No, it is specifically designed for digital event logging from SOE modules.

Recommended Related Models (Same Series or Compatible Modules)

| Model Number | Description | Function Type | Channels | Dimensions (mm) |

|---|---|---|---|---|

| INSES01 | Sequence of Events Slave Module | Digital Event Input | 16 | 50.8 x 177.8 x 215.9 |

| INSES02 | Advanced SOE Slave Module | Digital Input (Buffered) | 32 | 50.8 x 177.8 x 215.9 |

| INNIS11 | Network Interface Module | Network Communication | – | 50.8 x 177.8 x 215.9 |

| INNPM11 | Network Processing Module | DCS Control Interface | – | 50.8 x 177.8 x 215.9 |

| INFI90 | Central Processing Unit (DCS Core) | CPU Controller | – | 50.8 x 177.8 x 215.9 |

| IMMFP12 | Multifunction Processor | Redundant Control Processor | – | 50.8 x 177.8 x 215.9 |

Popular ABB Models (High-Demand Industrial Use)

| Model Number | Description | Application Area | Module Type | Weight (kg) |

|---|---|---|---|---|

| PM866AK02 | AC 800M Controller Module | Power & Process Control | CPU Module | 0.5 |

| AI835 | Analog Input 4-20mA Module | Process Automation | I/O Module | 0.3 |

| AO845 | Analog Output Module (8 channels) | Factory Automation | Output Module | 0.35 |

| CI860 | Modbus Communication Module | Industrial Networking | Interface Module | 0.25 |

| DI825 | Digital Input Module (24VDC) | Electrical Distribution | I/O Module | 0.28 |

| DO880 | Digital Output (Relay) Module | Actuator Control | Relay Module | 0.4 |

Excellent PLC

Excellent PLC