| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

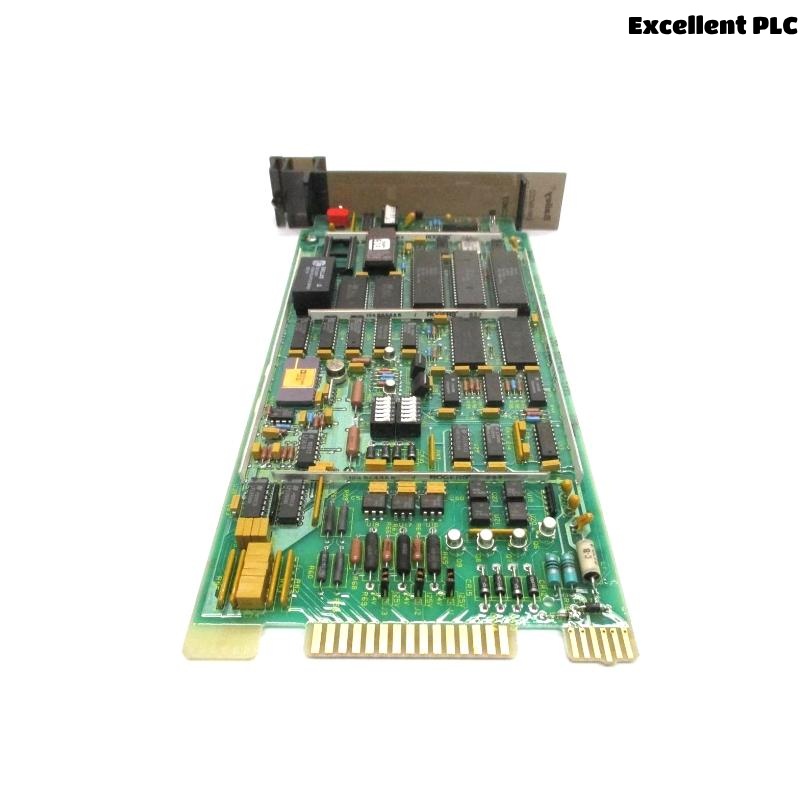

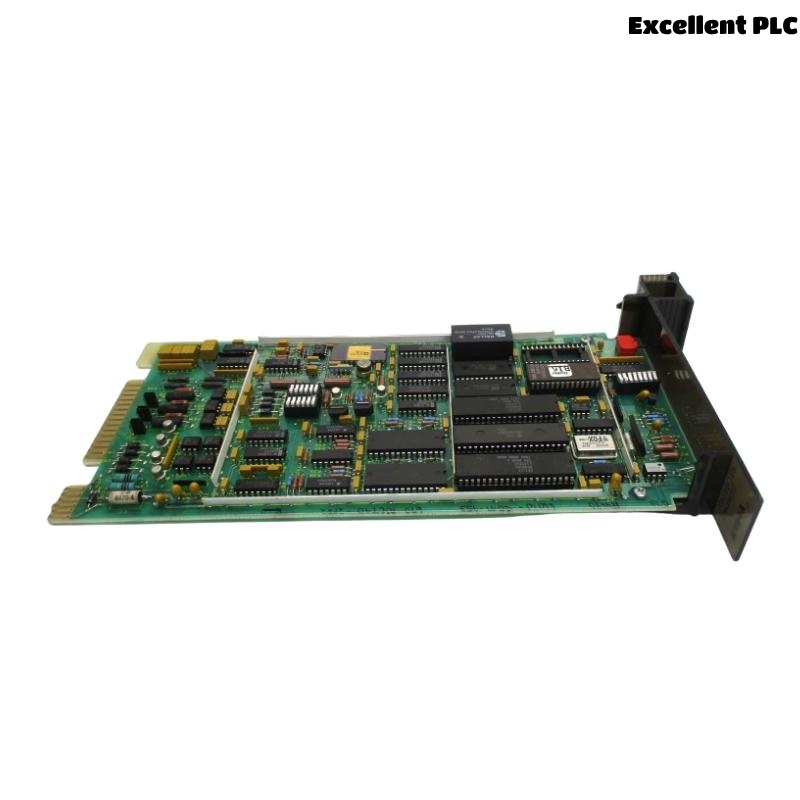

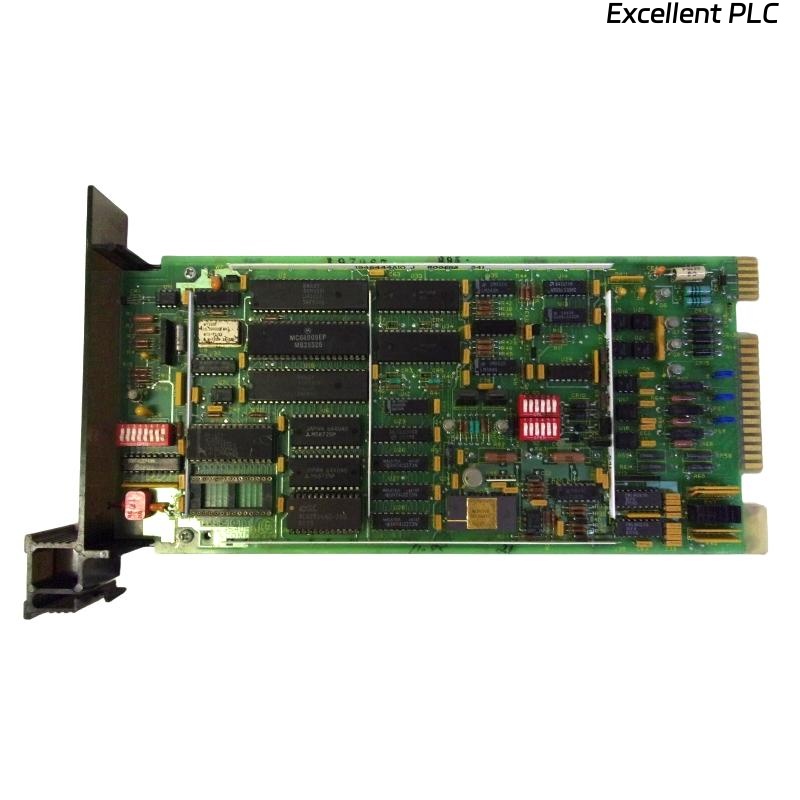

The ABB Bailey NCOM03 Enhanced Controller Module is an advanced communication and processing unit developed for use in the Bailey INFI 90 and Symphony DCS systems. As a central component in distributed control environments, the NCOM03 offers enhanced networking, synchronization, and data exchange functionalities. It acts as a controller interface, coordinating between various subsystems, field I/O, and control processors.

Built with industrial-grade hardware and firmware, the NCOM03 ensures precise control and high-speed communication, enabling real-time decision-making in complex automation environments. It supports the INFI-NET communication protocol and integrates seamlessly with other ABB Bailey components.

Product Specifications

| Parameter | Details |

|---|---|

| Product Name | NCOM03 Enhanced Controller Module |

| Part Number | NCOM03 |

| Manufacturer | ABB Bailey |

| System Compatibility | INFI 90, Symphony DCS |

| Module Type | Communication and Control Module |

| Communication Protocol | INFI-NET |

| Application Function | Network controller for DCS architecture |

| Supported Components | IMMFP12, INICT13A, INNIS21, I/O modules |

| Interface Type | High-speed backplane and INFI-NET ports |

| LED Indicators | Power, Module Active, Communication Status, Fault |

| Operating Voltage | Supplied through backplane (nominal 5 VDC) |

| Operating Temperature | 0°C to +60°C |

| Storage Temperature | -40°C to +85°C |

| Humidity Range | 5%–95% non-condensing |

| Shock and Vibration | 1g, 10–150 Hz; rugged industrial build |

| Mounting Type | Rack-mounted (Bailey-compatible chassis) |

| Regulatory Compliance | CE, UL, CSA, RoHS compliant |

| Dimensions (W x H x D) | 137 x 103 x 47 mm |

| Weight | 0.69 kg |

Product Applications

-

Power Generation Plants: For coordinating control between turbine, boiler, and auxiliary equipment.

-

Petrochemical Facilities: Integration of process monitoring and alarm systems.

-

Refineries and Oil Terminals: Enables synchronized control across distributed units and SCADA systems.

-

Water and Wastewater Treatment Plants: Manages I/O communication for pumps, flow controllers, and chemical dosing systems.

-

Pulp and Paper Industry: Handles supervisory control in continuous processing environments.

-

Mining and Metals Processing: Controls heavy-duty machinery, conveyors, and monitoring devices.

Product Advantages

-

Enhanced Communication Control: Central controller for INFI-NET networks with deterministic communication.

-

Real-time Synchronization: Maintains precise timing across multiple modules and subsystems.

-

High Reliability: Engineered for continuous operation in harsh environments with minimal maintenance.

-

Seamless Integration: Works with both legacy INFI 90 systems and upgraded Symphony DCS platforms.

-

Modular Design: Allows flexible expansion, redundancy, and component replacement.

-

Built-in Diagnostics: LED indicators allow for quick visual status checks and troubleshooting.

-

Long Product Lifecycle: Supported under ABB’s extended lifecycle services for legacy systems.

-

EMI-resistant: Designed for installations with high electromagnetic interference.

Frequently Asked Questions (FAQ)

1. What role does the NCOM03 play in a distributed control system?

The NCOM03 acts as a communication coordinator, managing data exchange across INFI-NET and ensuring synchronization between control modules and I/O nodes.

2. Can the NCOM03 be used in systems with existing NCIS01 or NCIS02 modules?

Yes. The NCOM03 integrates seamlessly with NCIS-series slave modules, acting as the communication controller for these devices.

3. Does the NCOM03 support redundancy?

Yes. Redundant NCOM03 modules can be configured to ensure uninterrupted communication and failover capabilities in critical applications.

4. How is the NCOM03 configured during setup?

Configuration is handled through ABB engineering tools integrated within the Symphony or INFI 90 control software suite. Parameters are set via the host controller.

5. What kind of diagnostics are available on the module?

LED indicators display real-time module status, communication activity, and fault alerts, aiding in rapid maintenance and troubleshooting.

6. Can the NCOM03 be hot-swapped during operation?

No. The module must be powered down before insertion or removal to prevent potential system faults or data loss.

7. What’s the maximum operating temperature for the NCOM03?

The module supports up to +60°C in industrial environments, making it suitable for control rooms and cabinet installations.

8. Is the NCOM03 still supported by ABB?

Yes. The NCOM03 is covered under ABB’s legacy lifecycle services and is widely used in ongoing DCS systems.

9. Can the NCOM03 connect directly to SCADA systems?

While the NCOM03 itself does not connect directly to SCADA, it communicates with interface modules like INICT13A, which bridge control data to external systems.

10. What industries typically deploy the NCOM03?

Industries such as power generation, petrochemicals, water management, and heavy manufacturing routinely use the NCOM03 in their DCS architectures.

Related Models (Same Series or Compatible)

| Model | Description | Function | System Compatibility | Weight (g) |

|---|---|---|---|---|

| NCOM01 | Controller/Network Communication Module | INFI-NET Communication Controller | INFI 90 | 830 |

| NCOM02 | Controller Module | Enhanced I/O Network Communication | INFI 90, Symphony | 840 |

| NCIS01 | I/O Slave Communication Module | Slave interface for I/O subsystems | INFI 90 | 800 |

| NCIS02 | I/O Slave Communication Module | Improved version of NCIS01 | INFI 90 | 820 |

| IMMFP12 | Multifunction Processor | Main process control CPU | INFI 90 | 950 |

| INICT13A | Network Interface Module | Gateway for INFI-NET to external HMI | INFI 90, Symphony | 770 |

Popular ABB Models (Same Brand, Different Series)

| Model | Product Type | Functionality | Application | Weight (g) |

|---|---|---|---|---|

| PM864AK01 | AC 800M CPU Controller | High-speed logic controller | 800xA System | 500 |

| CI854AK01 | Communication Interface Module | PROFIBUS linking interface | Industrial automation | 310 |

| TU830V1 | Terminal Base Unit | S800 DIN-rail base unit | Modular I/O | 250 |

| AI810 | Analog Input Module | 8-channel analog input | S800 I/O | 280 |

| DO840 | Digital Output Module | 16-channel digital output | Industrial discrete control | 270 |

| AC500 PM592-ETH | Modular PLC Controller | Ethernet-enabled, IEC 61131 PLC | Factory automation | 700 |

Excellent PLC

Excellent PLC