| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

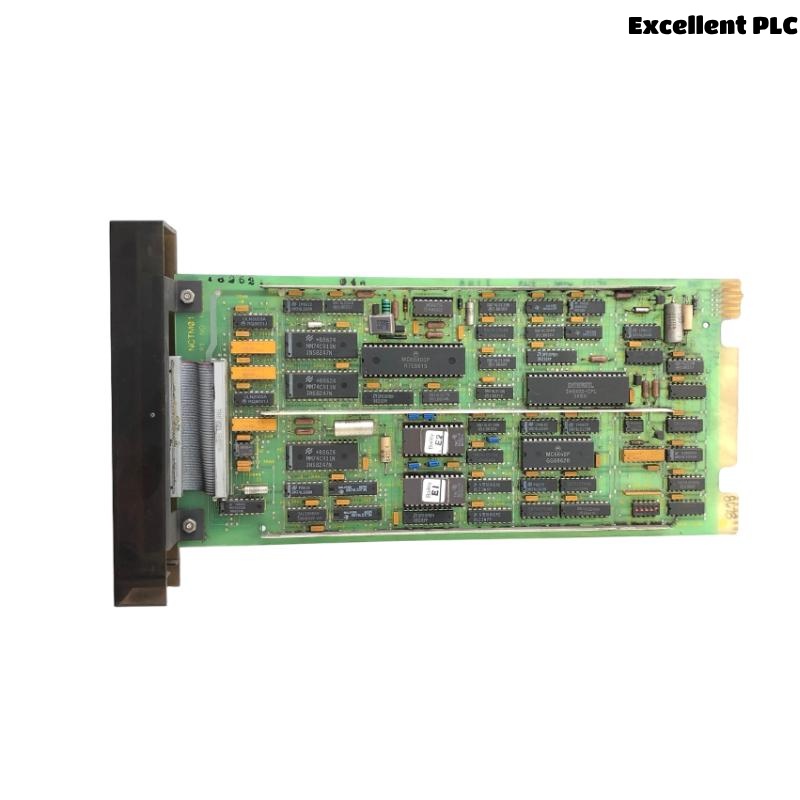

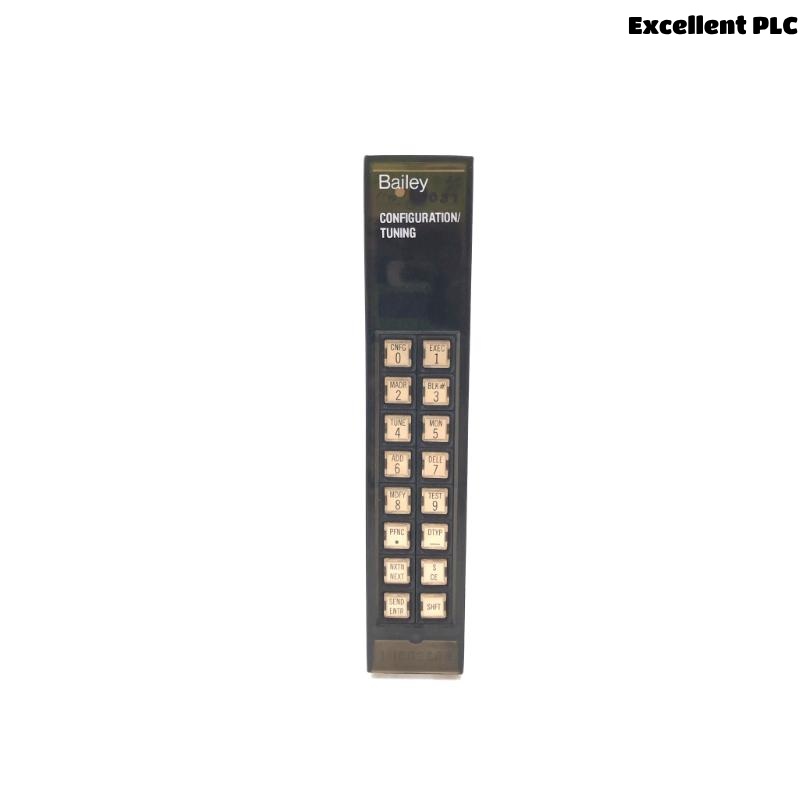

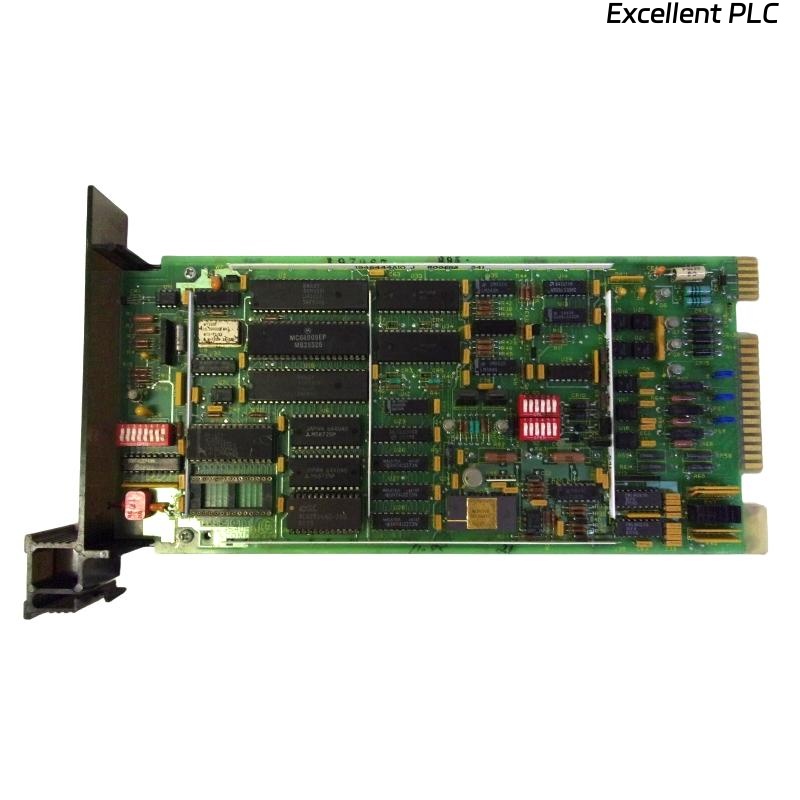

The ABB Bailey NCTM01 Configuration Tuning Module is a specialized tuning and configuration module designed for use within the INFI 90 Distributed Control System (DCS) architecture. This module plays a vital role in setting parameters, fine-tuning process variables, and performing system calibrations directly within the control environment. Its robust design enables plant operators and control engineers to implement process changes and validate configurations without disrupting live operations.

Developed by ABB under the Bailey legacy brand, the NCTM01 is a critical tool in maintaining optimal performance of process control loops and field devices. It interfaces seamlessly with control processors and communication modules in the INFI 90 and Symphony systems, ensuring consistent integration with ABB’s DCS solutions.

Product Specifications

| Parameter | Description |

|---|---|

| Product Name | Configuration Tuning Module |

| Model Number | NCTM01 |

| Manufacturer | ABB Bailey |

| System Compatibility | INFI 90, Symphony DCS |

| Module Type | Configuration & Tuning Module |

| Function | Parameter tuning, diagnostics, and configuration |

| Communication Protocol | INFI-NET via system backplane |

| Mounting Type | Rack-mounted (standard Bailey chassis) |

| LED Indicators | Status, Fault, Communication |

| Power Supply | 5 VDC supplied through INFI 90 backplane |

| Operating Temperature Range | 0°C to +60°C |

| Storage Temperature Range | -40°C to +85°C |

| Humidity Tolerance | 5% to 95% non-condensing |

| EMI/EMC Compliance | Industrial-grade compliance, shielded |

| Diagnostic Capabilities | Built-in fault detection, self-check routines |

| Configuration Interface | INFI 90 Engineering Workstation |

| Dimensions (W × H × D) | 178 x 51 x 330 mm |

| Weight | 0.4 kg |

Product Applications

The NCTM01 is used across a wide range of industrial environments that rely on high-availability distributed control systems:

-

Process Plant Optimization: Enables real-time parameter tuning and process variable adjustments for optimized control.

-

Commissioning and Startup: Used during initial system deployment to set up functional control loops and calibrate inputs.

-

Routine Maintenance and Diagnostics: Assists in identifying tuning issues or configuration drift in existing control loops.

-

Change Management: Facilitates structured updates to control strategies with minimal system disruption.

-

Industrial Automation Systems: Integrates with other Bailey modules to form a robust automation backbone in manufacturing or energy plants.

-

SCADA-Linked Infrastructure: Plays a key role in ensuring field tuning aligns with supervisory SCADA data requirements.

Product Advantages

-

Seamless Integration: Fully compatible with ABB’s INFI 90 and Symphony series, no complex interface modifications required.

-

Real-time Tuning: Allows on-the-fly parameter changes during system operation, without needing a shutdown.

-

Modular Design: Can be installed or removed independently from the control processor for flexible configuration.

-

Diagnostics Support: Built-in status and fault indicators provide immediate operational feedback.

-

Enhanced Maintainability: Simplifies loop tuning and calibration processes, reducing overall maintenance time.

-

Rugged Construction: Built to endure industrial conditions with superior temperature and EMI tolerance.

-

Centralized Control: Works directly with ABB configuration software for centralized system tuning and reporting.

-

Legacy Support: Maintained under ABB’s extended lifecycle program, ensuring availability and service continuity.

Frequently Asked Questions (FAQ)

1. How is the NCTM01 module physically installed within the INFI 90 system?

The NCTM01 is inserted into a standard Bailey rack-mounted chassis. It connects directly to the backplane, requiring proper alignment to engage power and communication paths.

2. What precautions should be taken before removing the NCTM01 from the rack?

Before removal, the power to the rack must be turned off to avoid potential damage to the backplane connectors or the module itself. Also, ensure configuration changes are saved externally.

3. Does the NCTM01 store any configuration data locally?

No, the NCTM01 acts as a configuration and tuning interface. All control and logic data remain in the control processor or central configuration workstation.

4. What kind of status feedback does the NCTM01 provide during operation?

It has onboard LED indicators for operational status, fault conditions, and communication activity. These provide immediate visual diagnostics without needing external tools.

5. Is the NCTM01 capable of monitoring control loop performance in real-time?

Yes, it allows live tuning and parameter adjustments, enabling engineers to assess loop behavior and make incremental modifications during plant operation.

6. How does the NCTM01 interact with engineering workstations like Composer?

It serves as a communication bridge to relay parameter changes from Composer or other configuration tools to the field control modules through the INFI-NET network.

7. Can the NCTM01 adjust field instrument calibration settings?

It does not directly calibrate instruments but facilitates parameter setting and loop tuning that may indirectly affect sensor interpretation or control setpoints.

8. What type of faults can the module detect and report?

The module can identify issues such as communication loss, improper configuration data, and internal hardware malfunctions, which are indicated by specific LED fault codes.

9. Are there compatibility limitations when using NCTM01 with newer ABB Symphony Plus systems?

While designed for legacy INFI 90 systems, NCTM01 remains compatible with many hybrid Symphony Plus configurations, especially those retaining INFI-NET backplane infrastructure.

10. What is the recommended maintenance interval or checkup procedure for NCTM01?

Recommends visual inspection during routine plant maintenance (typically every 12–18 months). Check LED indicators, confirm secure seating in the rack, and verify communication with the engineering workstation.

Related Models (Same Series or Functionally Compatible)

| Model | Description | Function | System Compatibility | Weight (g) |

|---|---|---|---|---|

| IMMFP12 | Multifunction Processor | Executes control logic | INFI 90 | 950 |

| INICT13A | Network Interface Module | External communications interface | INFI 90, Symphony | 770 |

| INNIS21 | Network Interface Slave | INFI-NET slave communication | INFI 90 | 780 |

| NCOM03 | Enhanced Communication Controller | Network sync and data exchange | INFI 90 | 850 |

| NCIS02 | I/O Slave Module | Communication with I/O subsystems | INFI 90 | 820 |

| INNPM22 | Power Module | Backplane power and diagnostics | INFI 90 | 600 |

Popular ABB Models (Same Brand, Other Platforms)

| Model | Product Type | Functionality | Application | Weight (g) |

|---|---|---|---|---|

| PM864AK01 | AC 800M CPU Controller | High-performance logic controller | ABB 800xA System | 500 |

| CI840A | Communication Interface Module | PROFIBUS DP interface | Field Device Communication | 310 |

| TU850V1 | Terminal Base Unit | Mounting base for S800 I/O modules | Modular I/O | 250 |

| AI830 | Analog Input Module | 8-channel analog input | ABB 800xA | 270 |

| DO820 | Digital Output Module | 16-channel DO, 24 VDC | Factory Automation | 290 |

| AC500 PM592-ETH | Modular PLC Controller | Ethernet-based controller | General Automation | 700 |

Excellent PLC

Excellent PLC