| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

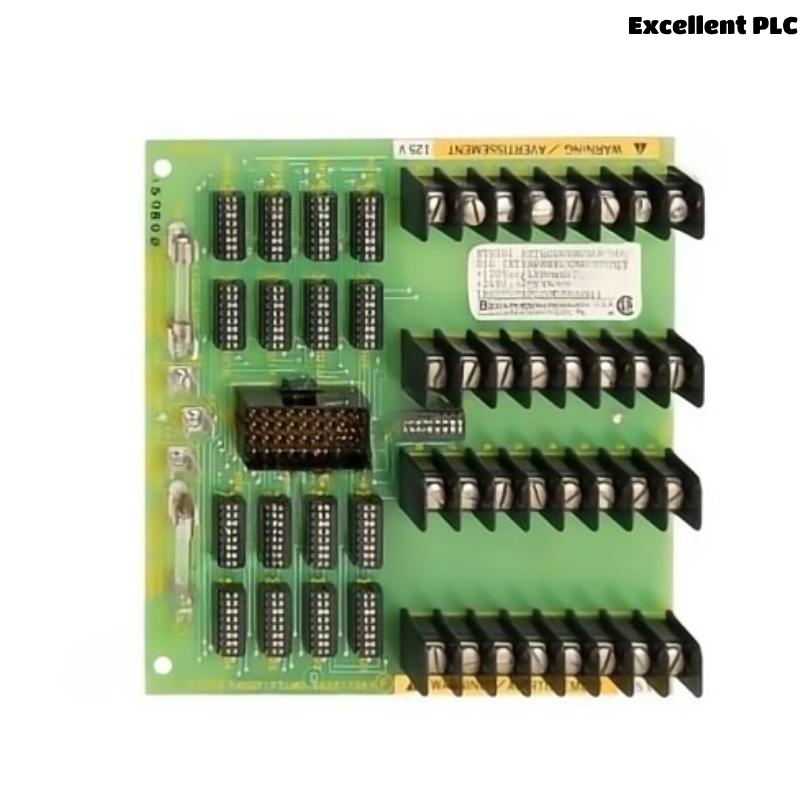

The ABB Bailey NTU-715 SM9-3055.051.00 is a Digital Input Termination Module (DITM) used in the Bailey INFI 90 Distributed Control System (DCS). It acts as a critical interface between field digital input devices and control processors, providing a secure and organized method to connect and manage multiple input signals. Designed to handle and route signals from switches, sensors, and push-buttons, this module ensures proper electrical termination and signal conditioning, crucial for accurate data acquisition in control systems.

The NTU-715 is commonly used with I/O modules like IMDSI or IMDSI02, where it facilitates safe and efficient signal transmission. By offering reliable screw-type terminal connections, insulation, and a layout that simplifies diagnostics and maintenance, the module enhances overall system reliability. Its passive design also ensures long-term performance without contributing to system power load.

As part of the Bailey legacy family, the NTU-715 helps facilities continue leveraging the robust and proven INFI 90 architecture while maintaining cost-effective operation and high availability in industrial automation settings.

Product Specification

| Parameter | Description |

|---|---|

| Model | NTU-715 |

| Part Number | SM9-3055.051.00 |

| Product Type | Digital Input Termination Module |

| System Compatibility | ABB Bailey INFI 90 / Net 90 Systems |

| Signal Type | Digital input (discrete ON/OFF signals) |

| Terminal Type | Screw terminal |

| Connection Capacity | 32 or more channels (depending on wiring configuration) |

| Wiring Type | Field wiring termination |

| Mounting | Rack or panel mount |

| Isolation Type | Optical or galvanic (handled by paired I/O processor) |

| Operating Voltage Range | Up to 125 VDC (field signal levels) |

| Power Supply Requirement | None (passive device) |

| Operating Temperature | 0°C to +60°C |

| Storage Temperature | -40°C to +85°C |

| Enclosure Rating | IP20 (when installed in cabinet) |

| Material | High-grade PCB with protective conformal coating |

| Dimensions (W x H x D) | 250 x 120 x 35 mm |

| Weight | 0.82 kg |

| Certifications | CE, UL, RoHS compliant |

Product Applications

The NTU-715 Digital Input Termination Module is widely applied in various industrial environments where reliable digital signal management is critical. It is typically found in:

-

Power Generation Plants – For status indication of circuit breakers, motor starters, and control relays.

-

Oil and Gas Facilities – Interfaces with field sensors and binary status indicators.

-

Chemical and Petrochemical Processing – Connects local switches, alarms, and safety shutdown devices.

-

Water and Wastewater Plants – Captures digital inputs from flow switches, level alarms, and pump status.

-

Pulp and Paper Mills – Tracks signals from machine interlocks, limit switches, and production stages.

-

Industrial Manufacturing – Supports process automation with inputs from push-buttons and safety sensors.

Product Advantages

-

Efficient Signal Termination: Ensures clean and accurate signal routing from field to control modules.

-

Passive, Maintenance-Free Operation: Requires no power and adds no load to the control system.

-

Legacy System Support: Fully compatible with ABB Bailey INFI 90 and Net 90 DCS architectures.

-

Reliable Field Wiring Interface: Designed for secure, easy-to-access screw terminal connections.

-

Space-Efficient Design: Compact form factor supports dense wiring layouts without excessive space use.

-

Industrial Durability: Rugged PCB with industrial coating ensures long-lasting performance in harsh environments.

-

Simple Installation: Can be quickly rack-mounted or panel-installed using standard methods.

-

System Integrity: Reduces wiring errors and simplifies troubleshooting during commissioning or maintenance.

-

Flexible Channel Support: Capable of accommodating numerous digital inputs per module.

-

Backed by ABB Lifecycle Services: Ensures spare parts, support, and upgrade paths for long-term use.

Frequently Asked Questions (FAQ)

-

How does the NTU-715 contribute to signal clarity and integrity in control systems?

The NTU-715 ensures accurate transmission of digital input signals by providing low-resistance termination points and organized wiring paths, minimizing the risk of signal interference, cross-talk, or data loss in noisy industrial environments. -

What considerations should be made when selecting cable types for wiring to the NTU-715?

Use shielded twisted-pair cables for long runs or high-EMI areas. Always follow ABB’s wiring guidelines to ensure proper grounding, shielding, and terminal torque specifications for safe and effective connections. -

Can the NTU-715 be used in redundant system configurations?

Yes. When used with redundant IMDSI modules or duplicated input circuits, the NTU-715 serves as a reliable interface, helping ensure both signal paths are correctly terminated without introducing signal degradation. -

What diagnostics or inspection routines are recommended for the NTU-715?

Regular visual inspection of terminal tightness, corrosion, and wiring integrity is recommended. Periodic torque checks on screw terminals and signal continuity verification using a multimeter are standard practices in preventive maintenance. -

How does the NTU-715 support modularity in large control systems?

Its compact and channel-dense design allows it to be installed in modular control cabinets, enabling scalable I/O expansion while maintaining organized termination and clear signal traceability. -

Is the NTU-715 suitable for safety instrumented systems (SIS)?

While the NTU-715 itself is a passive termination unit, it can be part of a safety-related signal chain when used with SIL-rated processors and input modules. Always consult system-level safety requirements before deployment in SIS applications. -

Can input signal noise or transient voltages affect NTU-715 performance?

The module’s passive design offers mechanical isolation via terminal layout, but for transient or inductive environments, external protection such as surge arrestors or input filtering should be implemented upstream. -

What documentation or markings assist with field installation?

Each terminal point on the NTU-715 is clearly labeled, and ABB provides detailed wiring diagrams and terminal block layouts to simplify installation, reduce commissioning errors, and ensure proper loop mapping. -

How does the NTU-715 integrate with remote I/O installations?

It can be mounted locally near field instruments or in remote junction boxes, allowing termination of digital signals before routing to centralized or distributed control processors through signal conditioning modules. -

What’s the proper decommissioning process for replacing an NTU-715?

Safely isolate power to the associated I/O circuits, label all wiring for traceability, remove field connections systematically, and replace the module following reverse steps, ensuring terminal torque is re-applied to manufacturer specs.

Related or Same-Series Models

| Model | Description | System Compatibility | Weight |

|---|---|---|---|

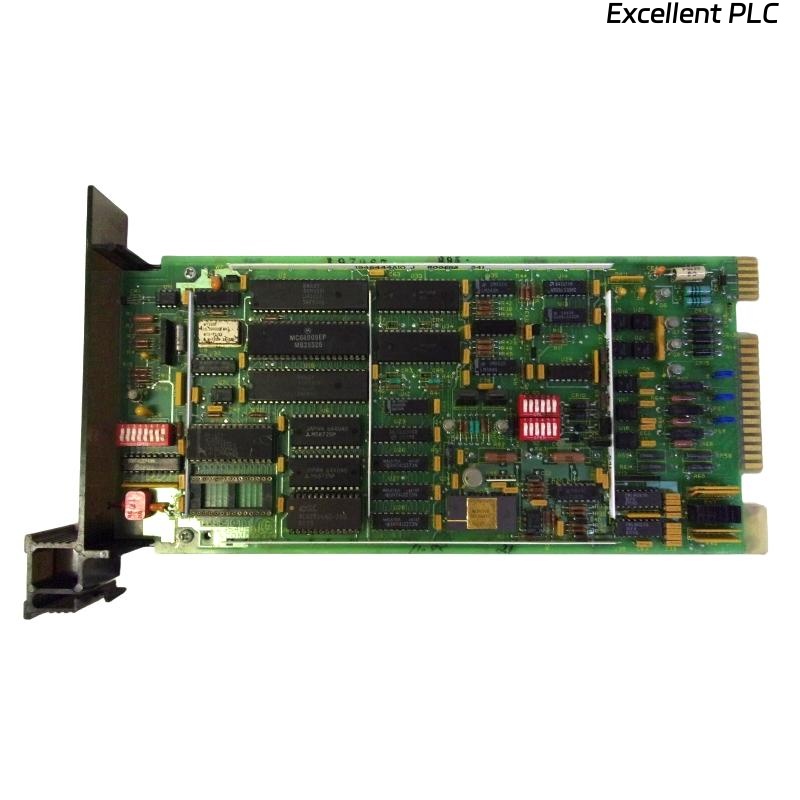

| IMDSI12 | Digital input module (with conditioning) | Bailey INFI 90 | 0.85 kg |

| NTU-816 | Digital output termination unit | Bailey INFI 90 | 0.48 kg |

| IMDSI02 | 32-point digital input processor module | Bailey INFI 90 / Net 90 | 0.90 kg |

| NIS02 | Network Interface Server Module | INFI 90 DCS | 0.80 kg |

| NTU-715S | Shielded version of NTU-715 | INFI 90 DCS | 0.52 kg |

| NTAI05 | Analog input termination unit | Bailey INFI 90 | 0.46 kg |

Popular ABB Models from the Same Brand

| Model | Description | Application Area | Weight |

|---|---|---|---|

| PM866-2 | High-performance CPU for AC 800M | Process automation | 0.75 kg |

| CI854AK01 | PROFIBUS-DP interface module for field communication | Fieldbus connectivity | 0.40 kg |

| TU830V1 | Terminal unit for S800 I/O modules | Signal interface unit | 0.25 kg |

| AC 800F | Modular controller for batch/hybrid systems | Hybrid and continuous control | 1.10 kg |

| CP635 | Touch HMI panel for operator interface | SCADA/HMI visualization | 1.20 kg |

| 07KT98 | Advant controller for legacy systems | Industrial control | 0.58 kg |

Excellent PLC

Excellent PLC