| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

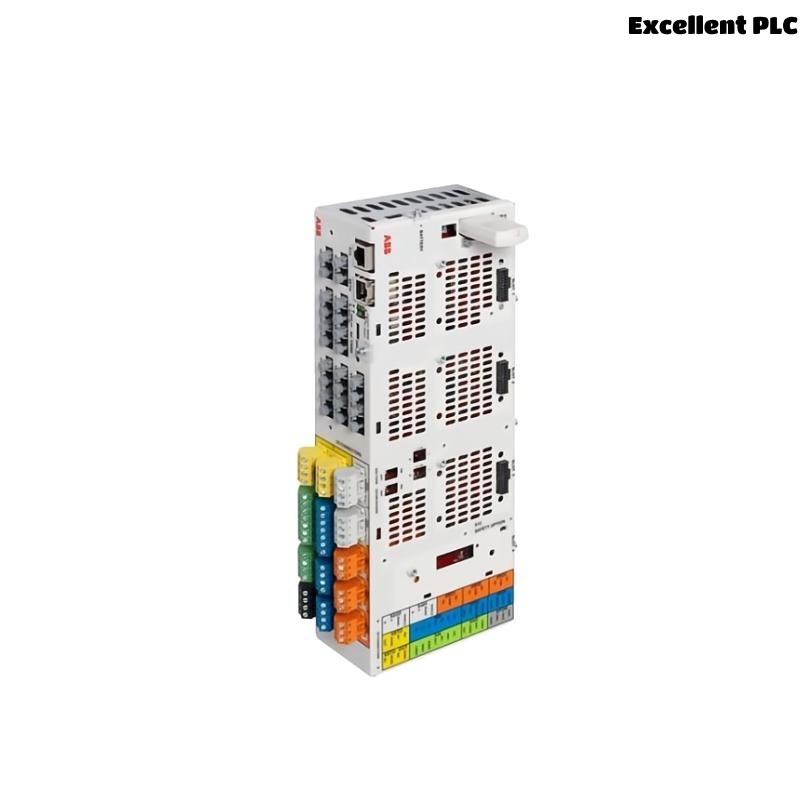

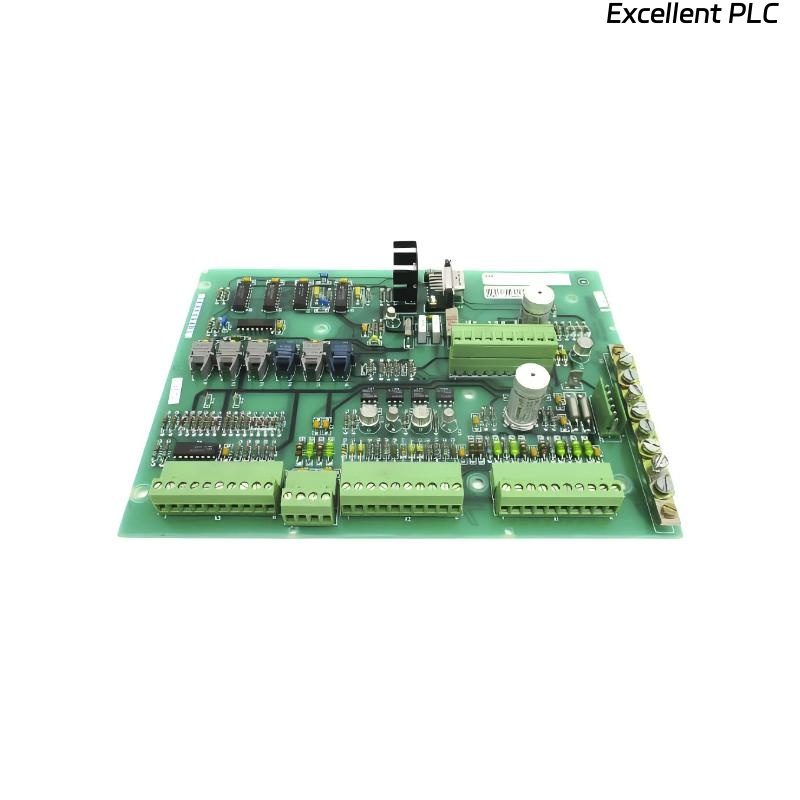

The ABB BCU-02 3AUA0000110429 Control Unit is a critical component within ABB’s industrial automation and control systems. This unit serves as a central processing module in medium-voltage drive systems, especially within the ACS6000 and similar series of drive solutions. It manages the real-time control algorithms necessary for optimal motor operation, safety monitoring, and communication with other control entities in the automation hierarchy.

Engineered with robustness and reliability in mind, the BCU-02 leverages ABB’s decades of expertise in industrial electronics to deliver high-performance processing capabilities, integrated communication functions, and seamless compatibility with ABB’s drive and control ecosystem.

Product Specifications

| Parameter | Description |

|---|---|

| Model | BCU-02 |

| Part Number | 3AUA0000110429 |

| Function | Control unit for medium-voltage drives |

| Application | ACS6000 series and compatible ABB drive systems |

| Processor Type | Embedded high-speed microcontroller |

| Memory | Integrated SRAM and Flash memory |

| Communication Interfaces | Fiber optic ports, RS485, CAN |

| Supported Protocols | MODBUS, ABB proprietary control protocols |

| Operating Voltage | 24V DC |

| Power Consumption | <15W |

| Operating Temperature | -10°C to +55°C |

| Storage Temperature | -40°C to +70°C |

| Humidity Range | 5% to 95% non-condensing |

| Mounting | DIN rail or panel mounting |

| Protection Class | IP20 |

| Dimensions (W x H x D) | 314 x 139 x 115 mm |

| Weight | 0.6 kg |

| Certifications | CE, RoHS, UL compliant |

| Software Tools | ABB DriveComposer, DriveWindow |

Applications

The ABB BCU-02 is widely used across several industries where medium-voltage motor control and process automation are critical. Key application sectors include:

-

Oil and Gas: Drives compressors and pumps under variable speed control.

-

Power Generation: Controls auxiliary motors and turbine systems.

-

Mining: Regulates conveyor belts, hoists, and crushers.

-

Pulp and Paper: Manages speed and torque control for rollers and cutters.

-

Water and Wastewater: Ensures energy-efficient pump and blower control.

Its reliable performance in harsh industrial environments makes it an ideal choice for mission-critical control systems.

Product Advantages

-

High Reliability: Engineered for continuous operation in demanding industrial settings.

-

Integrated Communications: Multiple interface options including fiber optics and serial buses for seamless integration.

-

Advanced Diagnostics: Built-in diagnostics allow predictive maintenance and reduce downtime.

-

Optimized for ABB Systems: Full compatibility with ACS6000 and similar ABB drives.

-

Compact Design: Efficient layout reduces panel space requirements.

-

Long Lifecycle Support: ABB offers long-term service, updates, and spare parts.

Frequently Asked Questions (FAQ)

-

Can the BCU-02 control unit be integrated with non-ABB drives?

Generally, it’s designed for ABB ACS6000 series, so integration with other brands is limited and may require custom configuration. -

What happens if the BCU-02 loses communication with the motor?

The unit will trigger fault conditions and safely stop the motor to avoid damage, following configured safety protocols. -

Is it possible to upgrade the firmware on the BCU-02 in the field?

Yes, firmware can be updated using ABB’s DriveComposer software without removing the unit from the panel. -

How often should the BCU-02 be inspected or maintained?

Routine inspection every 12 months is recommended, focusing on connectors, cooling, and firmware status. -

What diagnostic information can the BCU-02 provide during a fault?

It records fault codes, operating conditions, and status messages to help troubleshoot the cause quickly. -

Does the BCU-02 support redundant communication paths?

Yes, it can be configured with dual fiber optic connections to enhance system reliability. -

Can the BCU-02 operate in ambient temperatures above 55°C?

Continuous operation above 55°C is not recommended; for higher temperatures, additional cooling or alternative units should be considered. -

What safety features are built into the BCU-02?

It includes overcurrent protection, motor stall detection, and emergency stop integration to ensure operator and equipment safety. -

How does the BCU-02 handle power interruptions?

It supports controlled shutdown and restart sequences to protect connected motors and processes during power glitches. -

How is the BCU-02 mounted?

It can be mounted on a DIN rail or directly onto a panel.

Related ABB Models (Same Series/Category)

| Model | Part Number | Description |

|---|---|---|

| BCU-01 | 3AUA0000066464 | Previous generation control unit |

| BCU-03 | 3AUA0000110430 | Enhanced variant with extended protocol support |

| CI858A | 3BSE018135R1 | Communication interface for ControlBuilder |

| ACS6000 Drive | 3AUA0000094421 | Complete drive system compatible with BCU-02 |

| RET670 | 1MRK002791-AAB | Protection and control relay for MV systems |

| UNL12300-BCU | UNL12300-BCU | Universal Network Link controller for ABB drives |

Popular ABB Models

| Model | Part Number | Function |

|---|---|---|

| PM866 | 3BSE050198R1 | CPU module for AC 800M controller |

| CI854AK01 | 3BSE030220R2 | Profibus DP-V1 communication interface |

| TU830V1 | 3BSE013252R1 | Extended termination unit for AC800M |

| AI810 | 3BSE008516R1 | Analog input module, 8 channels |

| DO810 | 3BSE008510R1 | Digital output module, 16 channels |

| SD833 | 3BSE013234R1 | Optical module for redundancy applications |

Excellent PLC

Excellent PLC