| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

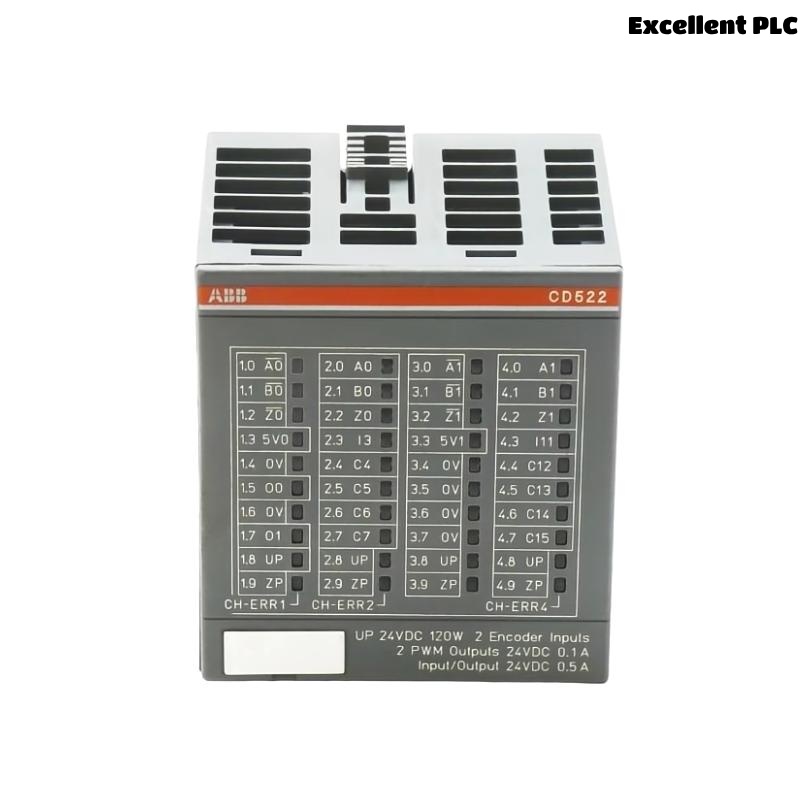

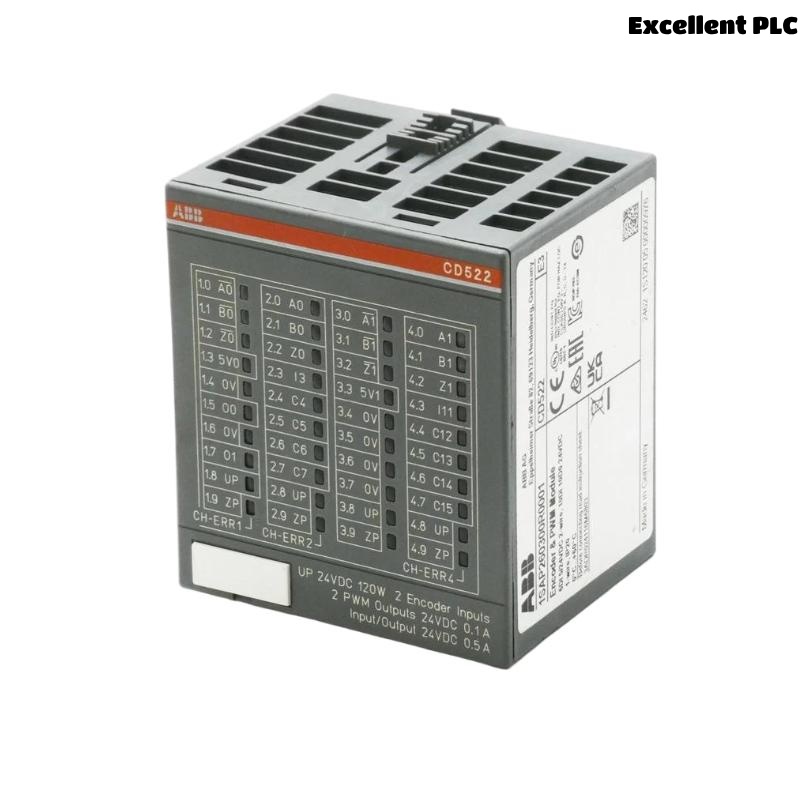

The ABB CD522 (1SAP260300R0001) Encoder Module is a high-performance module engineered to interface rotary or linear encoders with ABB’s AC500 PLC family. Designed to provide accurate, real-time position, speed, and direction feedback, the CD522 enables motion control in automation systems requiring precision and reliability.

The CD522 is equipped to handle differential encoder signals (RS-422) and incremental encoders, making it highly suitable for applications such as robotics, packaging, machine tools, material handling, and process automation. With integrated diagnostics, high input frequency, and robust build quality, this module ensures reliable operation even under industrial stress conditions.

Product Specifications

| Parameter | Specification |

|---|---|

| Model Number | CD522 |

| Product Code | 1SAP260300R0001 |

| Module Type | Encoder Interface Module |

| Signal Type Supported | Incremental encoder (RS-422 differential) |

| Number of Channels | 1 channel |

| Input Frequency | Up to 1 MHz |

| Power Supply | Supplied via backplane from AC500 CPU |

| Diagnostic Features | Encoder fault detection, signal loss indication |

| Encoder Voltage | 5 V DC (supplied to encoder) |

| Backplane Communication | ABB AC500 S500 system bus |

| Mounting Type | DIN Rail |

| Operating Temperature | -25°C to +60°C |

| Storage Temperature | -40°C to +85°C |

| Relative Humidity | 5–95%, non-condensing |

| Protection Class | IP20 |

| Certifications | CE, UL, cULus, RoHS compliant |

| Dimensions (W x H x D) | 62 × 76 × 67.5 mm |

| Weight | 0.124 kg |

Product Applications

The ABB CD522 Encoder Module is widely applied across industries that demand high-precision movement and tracking capabilities. Some common use cases include:

-

Industrial Robotics: Provides feedback for servo positioning and joint articulation.

-

Packaging Machinery: Tracks product position for accurate cutting, labeling, or sealing.

-

Conveyor Systems: Monitors position and speed of belts or rollers for automated sorting.

-

CNC Machines: Integrates with machine tools to control axis position and detect backlash.

-

Textile Machines: Ensures synchronization between rollers and cutting mechanisms.

-

Printing Industry: Enables precise control of print head or paper alignment systems.

Product Advantages

-

High-Speed Input Support: Handles encoder inputs up to 1 MHz, suitable for fast-moving machinery.

-

Diagnostic Transparency: Built-in fault detection helps maintain system uptime.

-

AC500 System Compatibility: Seamless integration with ABB’s AC500 PLC platform.

-

Compact & Modular: Small form factor saves space in control cabinets while maintaining expandability.

-

Reliable Power Supply: Receives power through the system bus, eliminating separate wiring for module operation.

-

Industrial Grade Durability: Designed to function under vibration, temperature fluctuations, and harsh environments.

-

Precise Positioning: Enables tight motion control loops when used in conjunction with AC500 CPUs and drive systems.

-

Reduced Wiring Complexity: Uses differential inputs, reducing noise and improving signal integrity in industrial environments.

Frequently Asked Questions (FAQ)

-

Q: What encoder types are supported by the CD522 module?

A: It supports incremental encoders with RS-422 differential output signals. -

Q: Can I connect multiple encoders to one CD522 module?

A: No, the CD522 supports one encoder per module. -

Q: What is the maximum pulse frequency the module can process?

A: It can handle signals up to 1 MHz, suitable for high-speed applications. -

Q: How is the encoder powered in this configuration?

A: The module provides a regulated 5 V DC supply for powering the encoder. -

Q: Does the CD522 require a separate power supply?

A: No, it is powered through the backplane from the AC500 PLC. -

Q: Can I monitor encoder signal status in the software?

A: Yes, the module provides diagnostic flags accessible via the ABB programming environment. -

Q: Is the CD522 hot-swappable?

A: No, modules should be installed or removed only when the system is powered down. -

Q: Which PLC series is the CD522 compatible with?

A: It is designed for use with ABB’s AC500 PLC series. -

Q: Can I use this module for absolute encoders?

A: No, CD522 is specifically for incremental encoders. For absolute encoders, other modules may be required. -

Q: What happens if the encoder cable is damaged or disconnected?

A: The module detects signal loss and generates a diagnostic alert to notify the user.

Related Models in the Same Series

| Model Number | Description | Key Features |

|---|---|---|

| CD521 (1SAP260200R0001) | Encoder module for SSI encoders | Supports absolute SSI encoders |

| DC541-CM | AC500 digital counter module | For counting applications up to 1 MHz |

| DI524 | Digital input module for fast response | 16 inputs, 24 VDC, fast pulse detection |

| DC541-C | Counter module with frequency inputs | 4 counter channels, 24 VDC |

| AX521 | Analog input module | 8-channel analog signal acquisition |

| TB511-ETH | Ethernet communication module for AC500 | Adds additional Ethernet ports |

Popular ABB Modules and Devices

| Model Number | Description | Application Area |

|---|---|---|

| AC500 PM583-ETH | High-performance AC500 CPU with Ethernet | Central control in industrial automation |

| CM579-RS | Communication module for serial ports | RS-232/485 expansion for AC500 |

| CP600 HMI Series | Human-Machine Interface for AC500 systems | Touch panel displays for control & monitoring |

| AI523 | 8-channel analog input module | Measurement of process signals (0–10V, 4–20mA) |

| DO524 | 16-channel digital output module | Relay or transistor output control |

| CI854A | PROFIBUS communication module | For connecting AC500 to PROFIBUS networks |

Excellent PLC

Excellent PLC