| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

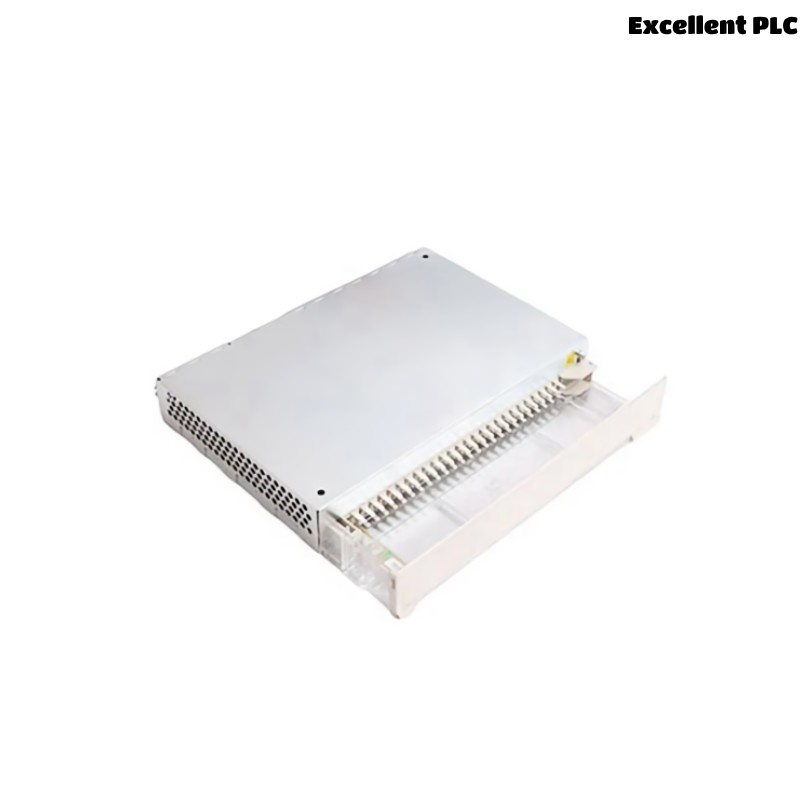

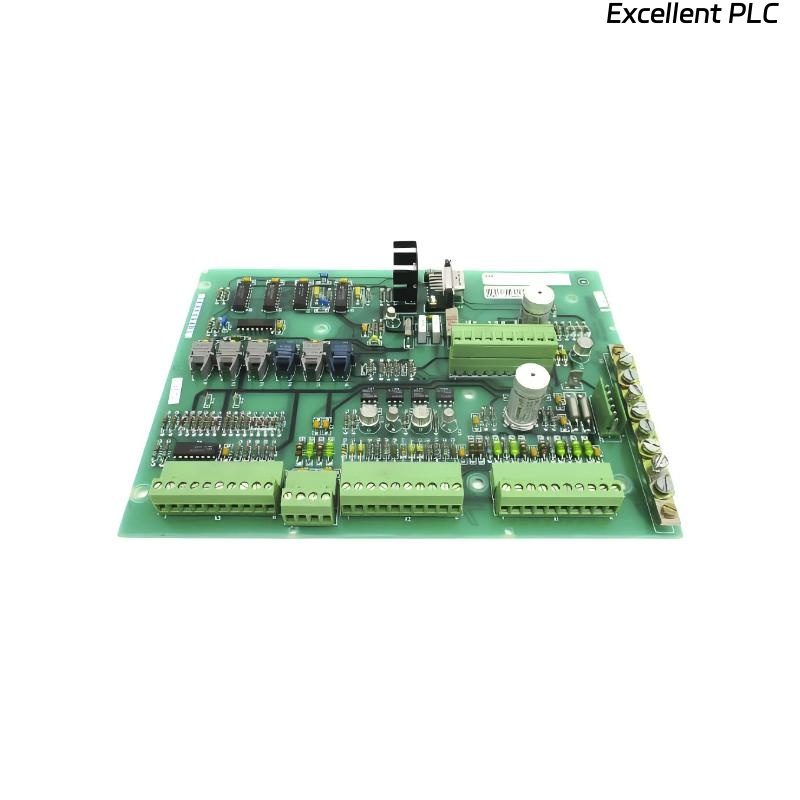

The ABB CI610 (part number: 3BHT300003R1) is an I/O Bus Extender Module used in conjunction with ABB’s Advant Controller 31 and other automation systems within the ABB industrial control ecosystem. Its primary function is to extend the input/output bus from the basic control unit to allow additional I/O modules to be connected beyond the default configuration limits.

As industrial automation systems grow in complexity and scale, the need for modular expansion becomes essential. The CI610 acts as a bridge module, maintaining high-speed data transmission and signal integrity across the extended I/O network. Its design ensures minimal signal loss and latency, which is vital for high-performance real-time industrial control applications.

Technical Specifications

| Parameter | Description |

|---|---|

| Product Name | I/O Bus Extender Module for Basic Unit |

| Model Number | CI610 |

| Part Number | 3BHT300003R1 |

| System Compatibility | Advant Controller 31, ABB Automation I/O systems |

| Function | Bus extension between base units and I/O modules |

| Bus Interface Type | ABB proprietary high-speed bus |

| Transmission Speed | High-speed digital backplane communication |

| Mounting Type | DIN rail mountable |

| Power Supply Voltage | Supplied via system bus |

| Current Consumption | Approx. 50 mA from system bus |

| Operating Temperature Range | 0°C to +60°C |

| Storage Temperature | -25°C to +70°C |

| Humidity | 5% to 95% RH, non-condensing |

| Protection Rating | IP20 |

| Shock/Vibration Resistance | Compliant with IEC 60068-2-6/27 |

| Cooling Method | Natural convection |

| Material | Industrial-grade thermoplastic (housing) |

| Color | Light grey (ABB standard) |

| Dimensions (H × W × D) | 252 x 273 x 40 mm |

| Weight | 1.195 kg |

Applications

The ABB CI610 is typically deployed in a wide variety of industrial automation setups where system scalability and modular design are necessary. Some typical application areas include:

-

Discrete and batch process automation

-

Advanced packaging systems

-

Food and beverage manufacturing

-

Pharmaceutical production

-

Water and wastewater treatment facilities

-

Power generation and distribution

-

Automotive assembly lines

-

Material handling systems

By using the CI610, engineers can expand control systems without redesigning the entire rack architecture, making it especially valuable in retrofit, upgrade, or custom expansion scenarios.

Product Advantages

-

Efficient System Expansion: Enables smooth integration of additional I/O modules without performance degradation.

-

High Reliability: Designed for continuous industrial operation under harsh environmental conditions.

-

Compact Form Factor: Slim and lightweight, saving valuable panel space in dense installations.

-

DIN Rail Mounting: Simplifies installation and ensures strong mechanical integrity.

-

Integrated Power Handling: Draws power directly from the bus, eliminating the need for external supply.

-

Stable Communication: Maintains data integrity across extended module chains.

-

Low Maintenance: Robust construction reduces the need for frequent servicing or part replacement.

-

Seamless Compatibility: Designed for ABB’s Advant Controller systems, ensuring plug-and-play functionality.

Frequently Asked Questions (FAQ)

1. What is the main function of the CI610 I/O Bus Extender?

It allows for the extension of I/O modules beyond the limitations of the basic control unit.

2. Is the CI610 compatible with all ABB controllers?

It is specifically designed for the Advant Controller 31 and related systems within ABB’s automation suite.

3. Does the CI610 require an external power source?

No, it is powered directly from the system bus.

4. How many I/O modules can I add using CI610?

This depends on the overall system architecture and power budget; typically several additional I/O modules can be added.

5. Can the CI610 be hot-swapped during operation?

No, the system should be powered down before installing or removing the CI610.

6. What is the maximum cable length for bus extension?

This is governed by ABB’s system design rules; usually, cable length should not exceed recommended bus distances (consult system manual).

7. Is the CI610 firmware-upgradable?

No, this module functions passively as a hardware bridge with no firmware or software interface.

8. How do I mount the CI610 in a control cabinet?

It is DIN rail mountable, with standard latching for quick installation.

9. Can the CI610 be used in redundant systems?

Yes, when configured properly, CI610 can be part of a redundant I/O architecture.

10. What maintenance does the CI610 require?

Minimal—just occasional visual inspections for dust accumulation or connection wear.

Related Models (Same Series or Functional Equivalents)

| Model Number | Description | Compatibility | Function |

|---|---|---|---|

| CI626 | Serial Communication Module | Advant Controller 31 | Serial data interface |

| CI631 | Fieldbus Communication Module (Profibus) | Advant Controller 31 | Fieldbus communication |

| CI532V02 | Ethernet Module | AC 800M | Network interface |

| DO620 | Digital Output Module (16 channels) | AC 800M I/O | Binary signal output |

| DI620 | Digital Input Module (16 channels) | AC 800M I/O | Binary signal input |

| TU810 | Base Terminal Unit | AC 800M I/O | I/O terminal wiring |

Popular ABB Industrial Automation Models

| Model Number | Description | Type | Application |

|---|---|---|---|

| PM864AK01 | AC 800M Controller CPU Module | Processor | Central process control |

| CI854AK01 | Profibus DP Interface Module | Communication Module | Field device communication |

| AI810 | Analog Input Module (8 channels) | Analog Input | Sensor signal acquisition |

| DI810 | Digital Input Module (16 channels) | Digital Input | Binary input control |

| DO810 | Digital Output Module (16 channels) | Digital Output | Actuator control |

| TU830V1 | Extended Base Terminal Unit | Terminal Base | Multi-channel I/O connections |

Excellent PLC

Excellent PLC