| Company Information | ||||||||

| sales@xmjzjsgs.com | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

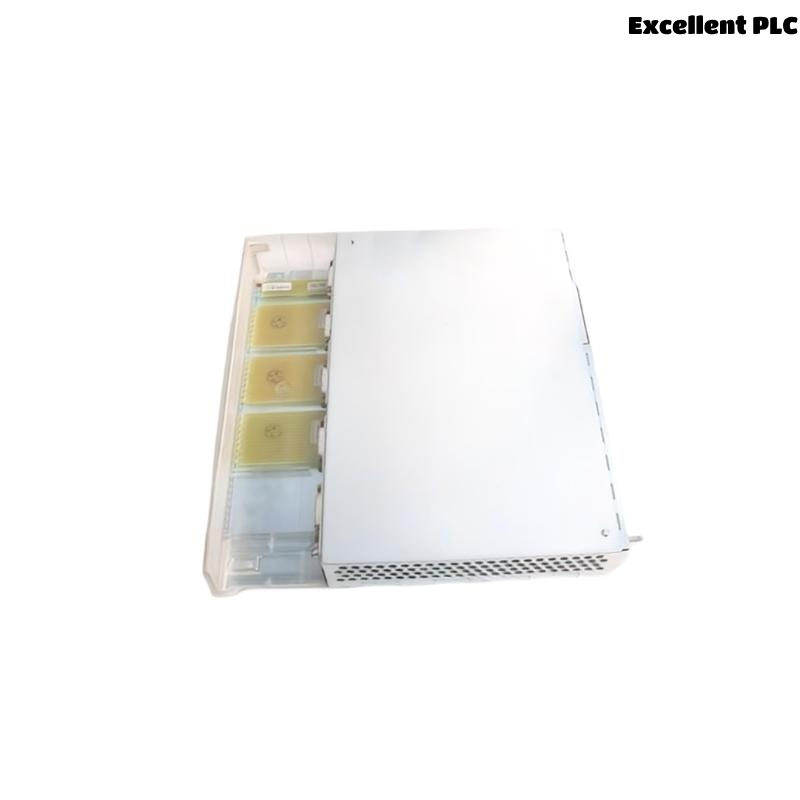

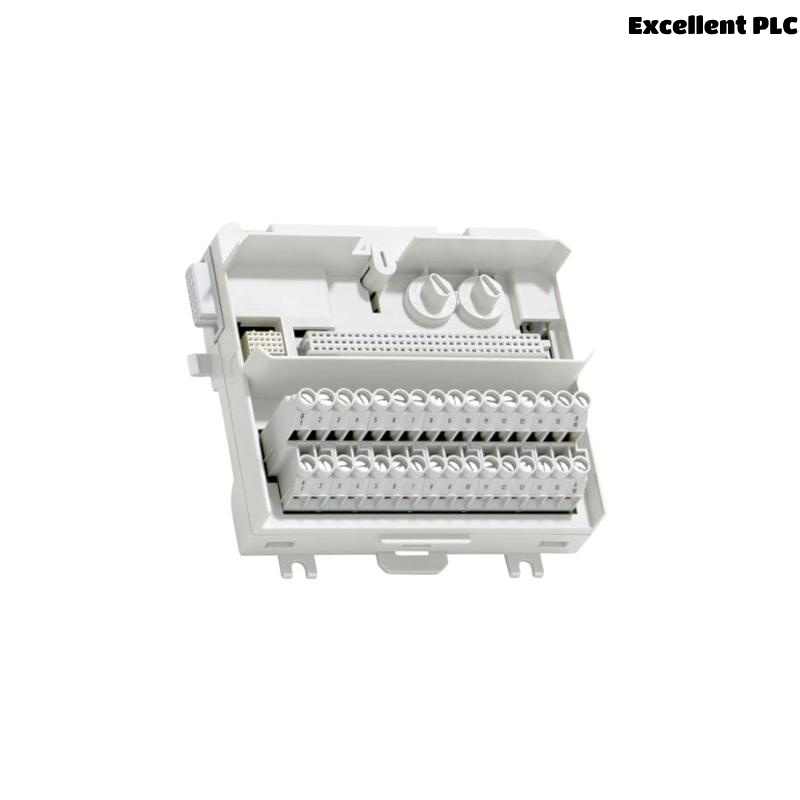

The ABB DP620 (3BHT30016R1) High Speed Counter module is designed to serve as a crucial part of ABB’s CI670 automation system. It is specifically engineered to count high-frequency pulses from various sensor types in real-time with great accuracy. This module excels in scenarios where rapid and reliable counting of events or pulses is essential for monitoring and controlling industrial processes.

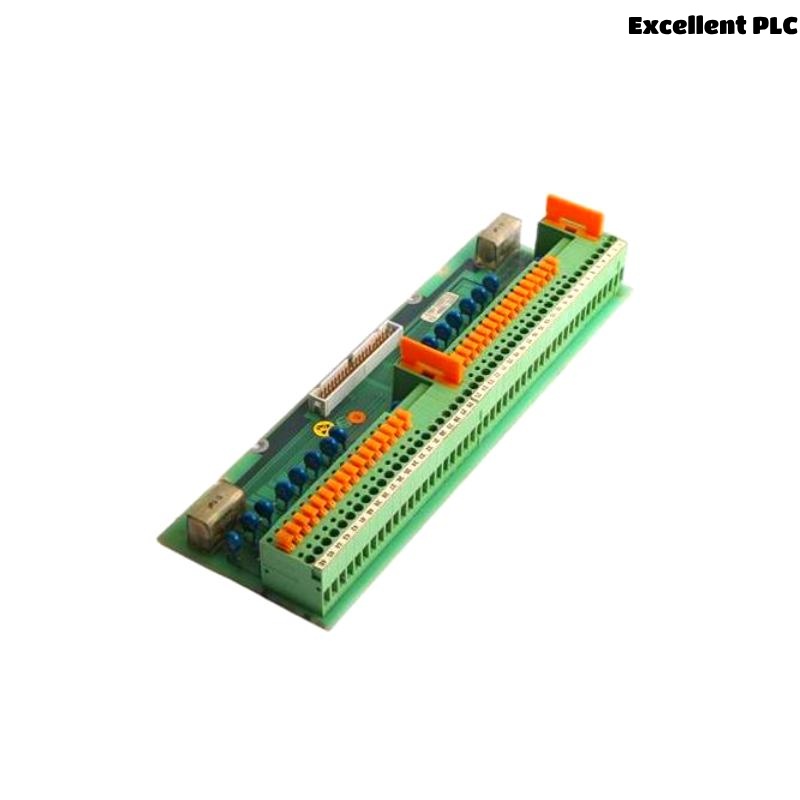

Equipped with multiple input channels, the DP620 can process signals with frequencies reaching up to 1 MHz. The design accommodates various industrial sensor standards including TTL, HTL, and NAMUR, making it highly versatile. Its robust build ensures stable performance even under harsh environmental conditions, which is critical for industrial automation applications.

The DP620 integrates seamlessly into complex control systems, providing essential data for process optimization, machinery synchronization, and productivity enhancement.

Product Specifications

| Parameter | Specification |

|---|---|

| Model Number | DP620 3BHT30016R1 |

| Product Type | High Speed Counter Module |

| Number of Input Channels | Up to 8 channels |

| Maximum Counting Frequency | Up to 1 MHz (depending on input type) |

| Supported Input Types | TTL, HTL, NAMUR compatible |

| Power Supply Voltage | 24 V DC |

| Power Consumption | Approximately 5 Watts |

| Operating Temperature | -20 °C to +70 °C |

| Storage Temperature | -40 °C to +85 °C |

| Relative Humidity | 5% to 95% (non-condensing) |

| Dimensions (W x H x D) | 252 x 273 x 40 mm |

| Weight | 1.635 kg |

| Mounting Method | DIN rail or panel mounting |

| Communication Interface | ABB proprietary CI bus |

| Certifications | CE, Industrial EMC standards |

Product Applications

The ABB DP620 High Speed Counter module finds its use across a wide range of industrial sectors where precision counting and fast signal processing are critical:

-

Manufacturing: Monitoring production line speeds, counting parts and cycles to maintain process consistency.

-

Packaging: Accurate counting of packaged units and synchronization with conveyor belts to avoid product loss.

-

Material Handling: Tracking quantities of items moved on conveyors or automated systems for inventory accuracy.

-

Textile Industry: Counting rotations and cycles for machinery operation monitoring and quality control.

-

Printing Industry: Counting sheet feeds or print cycles to ensure operational efficiency.

-

Energy Sector: Monitoring rotational speed of turbines and generators to optimize performance and detect faults.

Product Advantages

-

High-Frequency Counting Capability: Can handle input frequencies up to 1 MHz, suitable for very fast process signals.

-

Multiple Input Channels: Supports up to eight inputs simultaneously, allowing flexible and complex counting tasks.

-

Robust Industrial Design: Built to withstand harsh industrial conditions with a wide operating temperature range and humidity tolerance.

-

Broad Input Compatibility: Supports TTL, HTL, and NAMUR signals, enabling integration with various sensor types.

-

Compact and Space-Efficient: Standardized dimensions for DIN rail and panel mounting, saving valuable control cabinet space.

-

Reliable and Accurate: Ensures precise counting for critical process control and data acquisition.

-

Diagnostic Features: Equipped with LED indicators and fault detection for easier maintenance and troubleshooting.

-

Energy Efficient: Low power consumption supports sustainable industrial operations.

-

Seamless Integration: Fully compatible with ABB CI670 series, allowing smooth system-wide automation solutions.

Frequently Asked Questions (FAQ)

-

What is the maximum frequency the DP620 can reliably count?

It supports counting frequencies up to 1 MHz depending on signal type and environmental conditions. -

How many channels does the DP620 support?

The module supports up to 8 input channels, which can be individually configured. -

Which signal types can the DP620 accept?

It accepts TTL, HTL, and NAMUR signals, making it adaptable to different sensor technologies. -

What are the power requirements for the DP620?

The module operates on a 24 V DC power supply, commonly provided within ABB automation systems. -

Is the DP620 suitable for use in extreme temperatures?

Yes, it operates reliably between -20 °C and +70 °C, making it fit for most industrial environments. -

How is the DP620 mounted within a control cabinet?

It can be mounted on DIN rails or panels according to installation preferences. -

Does the DP620 provide diagnostics for faults or errors?

Yes, it includes LED indicators for status monitoring and fault detection to aid maintenance. -

Can the DP620 integrate with other ABB CI670 modules?

Yes, it is designed to work seamlessly within the CI670 automation platform. -

What kind of communication interface does the DP620 use?

The module uses ABB’s proprietary CI bus for communication with the control system. -

How heavy is the DP620 module?

The unit weighs 1.635 kg, making it easy to handle during installation.

Recommended Related Models (Same Series / Related ABB CI670 Modules)

| Model Number | Description | Key Feature |

|---|---|---|

| CI670 3BHT300017R1 | Bus Interface Module | High-speed communication bus |

| DP620 3BHT30016R1 | High Speed Counter Module | Fast pulse counting |

| CI670 3BHT300019R1 | I/O Interface Module | Digital and analog I/O support |

| CI670 3BHT300020R1 | Processor Module | Central processing unit |

| CI670 3BHT300022R1 | Power Supply Module | 24 V DC power supply |

| CI670 3BHT300023R1 | Diagnostic Interface Module | System diagnostics and status |

Popular ABB Models (Other ABB Control & Automation Products)

| Model Number | Product Type | Application |

|---|---|---|

| AC500 | Programmable Logic Controller | Industrial automation |

| Freelance DCS | Distributed Control System | Process control |

| ABB Ability System 800xA | Integrated Control System | Plant-wide automation |

| PM800 | Power Meter | Energy monitoring |

| ABB ACS880 | Variable Frequency Drive | Motor speed and torque control |

| RTU560 | Remote Terminal Unit | Remote monitoring and control |

Excellent PLC

Excellent PLC