| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

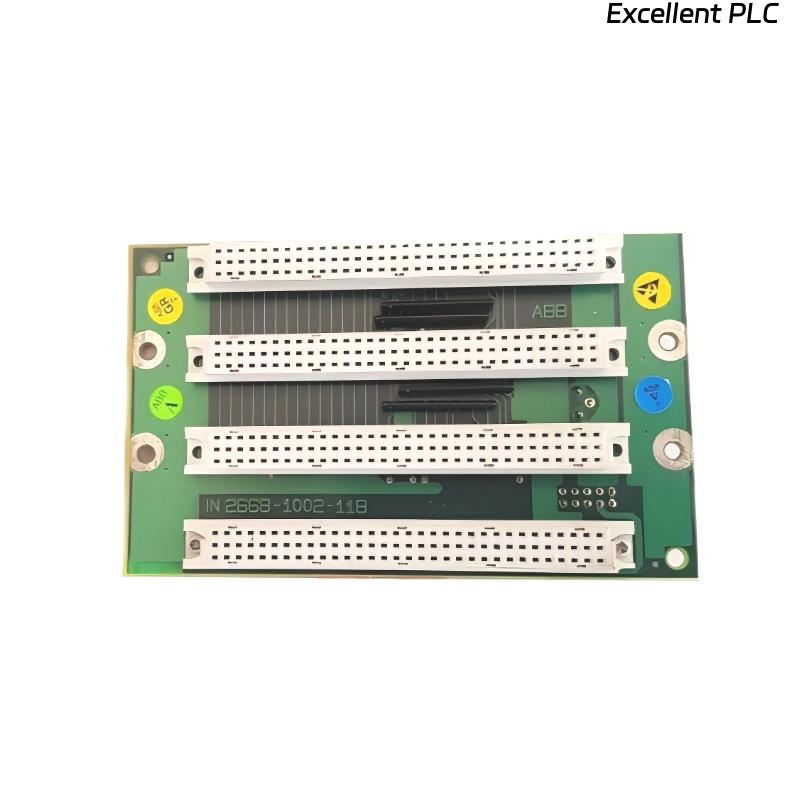

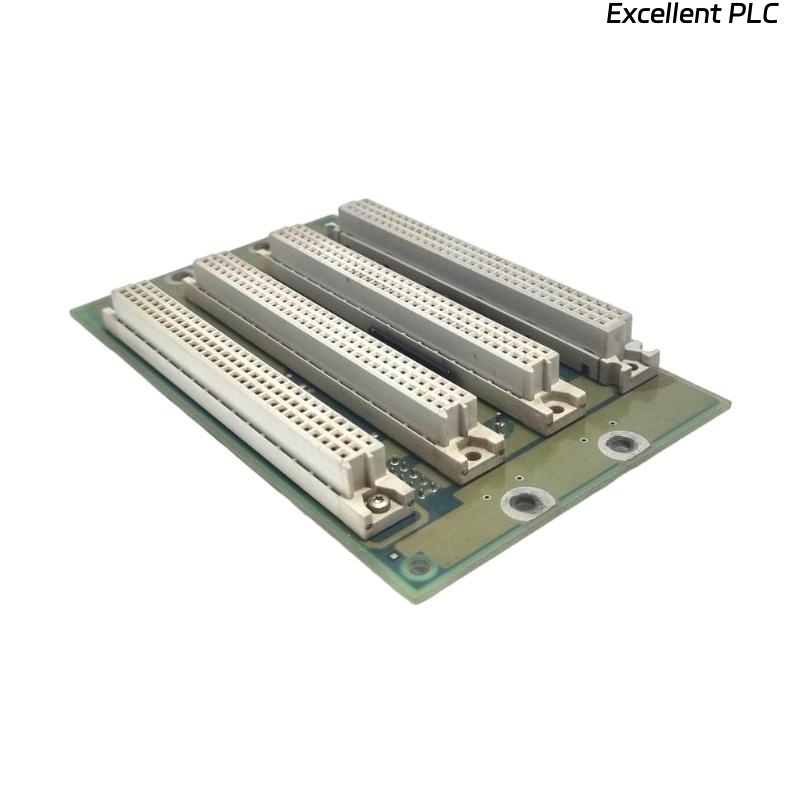

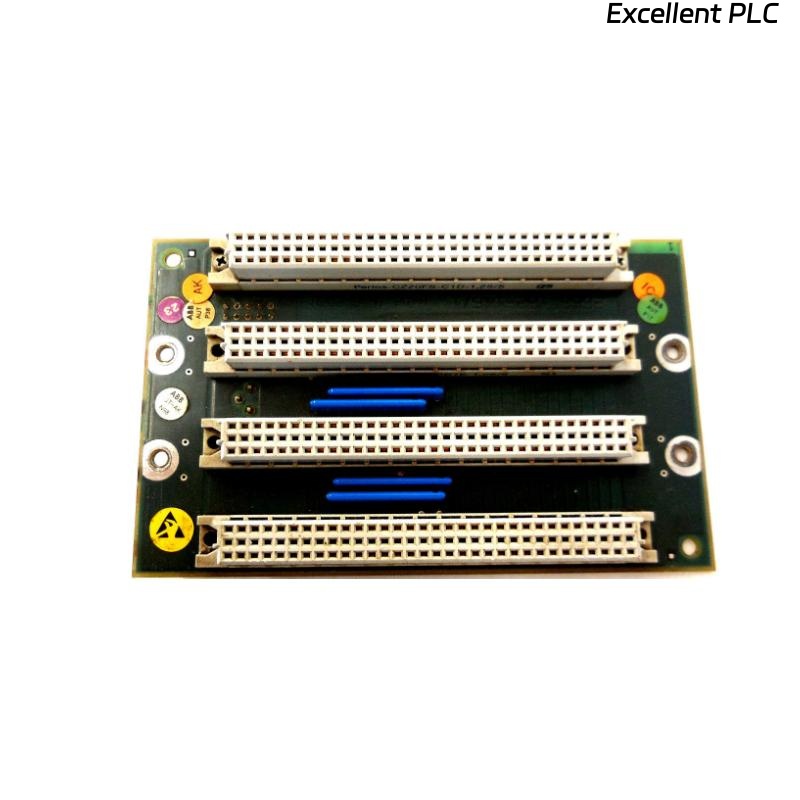

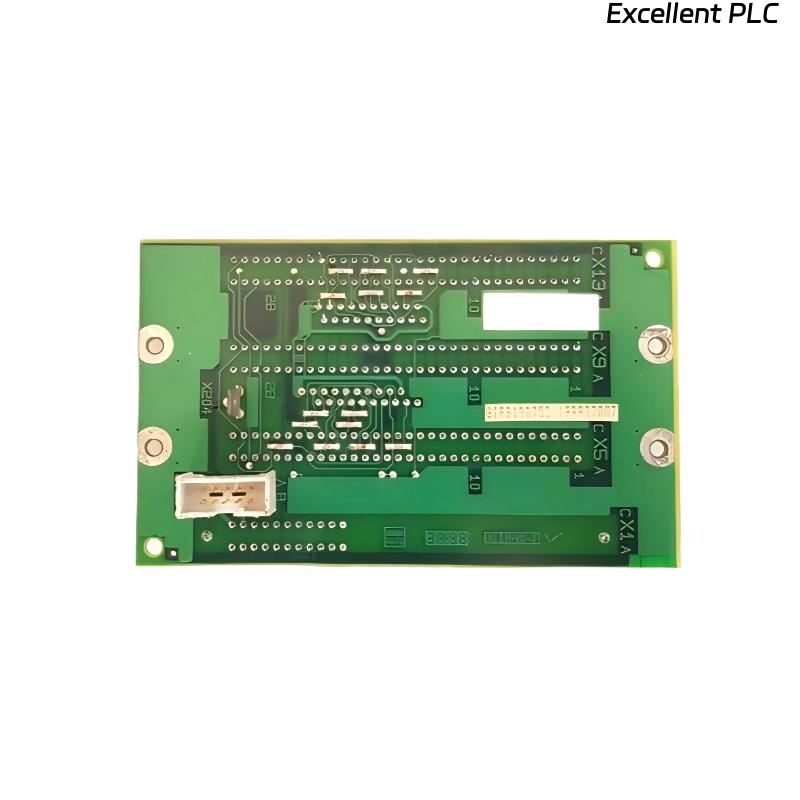

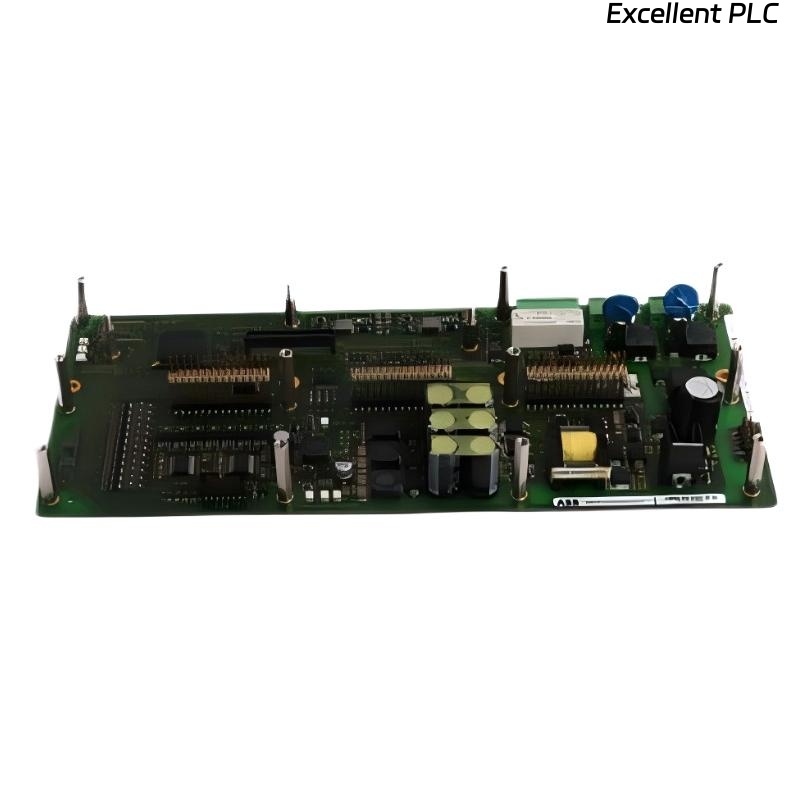

The ABB DSBB 175 57310256-CC backplane is a crucial component in ABB’s modular control systems, providing a stable communication interface between various input/output modules and control units. This backplane is designed to be integrated into distributed control systems (DCS), ensuring efficient data exchange and seamless connectivity across different system components.

Built to handle complex industrial environments, the DSBB 175 backplane is used in applications where reliability, data integrity, and high-speed communication are vital. It is particularly well-suited for industries such as manufacturing, energy management, process control, and automation, where precise control and monitoring are essential.

Product Specifications

| Parameter | Specification |

|---|---|

| Model | ABB DSBB 175 57310256-CC |

| Type | Backplane |

| Dimensions | 160 x 100 x 50 mm |

| Weight | 0.5 kg |

| Material | Metal Alloy |

| Power Supply | 24V DC ±20% |

| Signal Type | Digital and Analog |

| Supported Modules | Compatible with ABB I/O Modules |

| Communication Protocol | ABB Proprietary Protocols |

| Mounting Type | DIN Rail Mounting |

| Operating Temperature | -20°C to 60°C |

| Protection | Overvoltage, Overcurrent Protection |

Product Applications

The ABB DSBB 175 backplane is designed for a wide range of industrial and control applications where reliable, high-speed communication between modules is essential. Its key applications include:

-

Distributed Control Systems (DCS): The DSBB 175 serves as a central communication hub for connecting various control and I/O modules in DCS configurations, ensuring data integrity and real-time performance.

-

Manufacturing Automation: Used to connect and integrate sensors, actuators, and controllers, the DSBB 175 enables seamless communication across automated production lines.

-

Process Control Systems: In industries such as chemical, oil and gas, and pharmaceuticals, the DSBB 175 facilitates data transfer between field devices and control units, ensuring accurate and timely process control.

-

Energy Management Systems: Used to connect power monitoring systems, the DSBB 175 ensures reliable communication between devices that track and control energy consumption and distribution.

-

Power Generation: In power plants, the DSBB 175 helps link control equipment and monitoring systems to optimize the generation, distribution, and management of electricity.

-

Building Automation Systems (BMS): The backplane integrates control devices and systems used to manage building operations, such as lighting, HVAC, and security systems.

Product Advantages

-

Efficient Data Transmission: The DSBB 175 backplane is designed to handle high-speed data communication between control modules and I/O devices, ensuring minimal latency and optimal system performance.

-

Flexible Integration: Compatible with a wide range of ABB’s I/O modules, this backplane allows easy expansion and flexibility in system design.

-

Compact and Robust Design: With compact dimensions (160 x 100 x 50 mm) and a solid build, the DSBB 175 offers durability and space-saving advantages in industrial control panels.

-

DIN Rail Mounting: The backplane is designed for DIN rail installation, making it easy to mount in standard control panels, simplifying the setup and integration process.

-

High Protection Standards: Built with overvoltage and overcurrent protection, the DSBB 175 safeguards against electrical surges, enhancing the safety and longevity of the entire system.

-

Temperature Tolerance: The backplane operates effectively in a wide temperature range of -20°C to 60°C, making it ideal for use in both standard and harsh industrial environments.

-

Modular and Scalable: As part of ABB’s modular control system, the DSBB 175 backplane can be easily integrated into large-scale systems, allowing for future expansion as the application demands increase.

FAQ

1. What is the primary function of the DSBB 175 backplane?

The DSBB 175 serves as the central communication interface between various I/O modules and control units in a distributed control system, enabling efficient data exchange and system connectivity.

2. How many channels does the DSBB 175 backplane support?

The DSBB 175 is designed to support multiple digital and analog channels, depending on the connected modules. It is compatible with a wide variety of ABB I/O modules.

3. What is the power supply requirement for the DSBB 175?

The DSBB 175 operates on a 24V DC power supply with a ±20% tolerance, making it suitable for most industrial control systems.

4. What types of signals are supported by the DSBB 175?

The DSBB 175 supports both digital and analog signals, making it adaptable for a wide range of industrial applications.

5. What communication protocols does the DSBB 175 use?

The DSBB 175 utilizes ABB’s proprietary communication protocols to ensure seamless integration and reliable communication with other ABB control systems and modules.

6. How is the DSBB 175 mounted?

The DSBB 175 is designed for DIN rail mounting, providing ease of installation in control panels and other system enclosures.

7. What type of protection is included with the DSBB 175?

The DSBB 175 features overvoltage and overcurrent protection, ensuring the safety and durability of the system under varying electrical conditions.

8. What is the operating temperature range of the DSBB 175?

The DSBB 175 operates within a temperature range of -20°C to 60°C, making it suitable for use in various industrial environments.

9. Can the DSBB 175 be used in outdoor environments?

While the DSBB 175 is designed for industrial control systems, it should be installed in enclosed environments to protect it from direct exposure to harsh weather conditions.

10. How does the DSBB 175 improve system scalability?

The DSBB 175 supports multiple I/O modules and can be easily expanded, allowing the system to scale and accommodate additional modules as needed.

Recommended Models

| Model Number | Description |

|---|---|

| DSBB 110 | Compact Backplane for Modular Systems |

| DSBB 120 | High-Speed Backplane for Large Systems |

| DSBB 130 | Dual Bus Backplane for Redundant Systems |

| DSBB 140 | Backplane for Energy Management Systems |

| DSBB 150 | Advanced Backplane with Extended Capacity |

| DSBB 160 | Modular Backplane for Industrial Automation |

Popular ABB Models

| Model Number | Description |

|---|---|

| DSAI 301 | DS Analog Input Module |

| DSAO 120 | DS Analog Output Module |

| DSAI 302 | High-Speed Analog Input Module |

| DSAO 130 | Precision Analog Output Module |

| DSAI 100 | Digital Input & Output Module |

| DSAV 100 | Video Output Module |

Excellent PLC

Excellent PLC