| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Overview

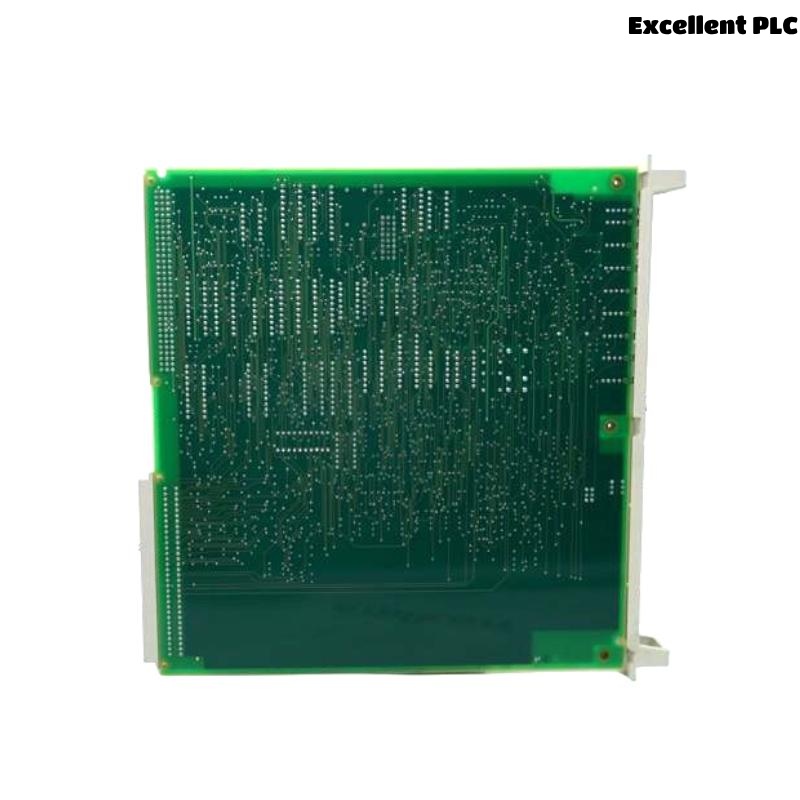

The ABB DSBC 176 (Part Number: 3BSE019216R1) is a bus extender board specifically designed to extend the communication interface within ABB’s Advant Controller 410 series and related industrial automation systems. This module serves as a critical component for expanding the backplane communication architecture, allowing the controller system to communicate seamlessly across extended or distributed racks.

In complex automation installations, where multiple controller boards and I/O modules are housed in separate physical enclosures or distant rack sections, the DSBC 176 acts as a bridge—preserving timing, data integrity, and synchronization. It ensures high-speed, reliable communication in mission-critical environments where downtime is not an option.

The DSBC 176 is part of ABB’s trusted Advant Master product line, which is known for long-term reliability, robustness, and seamless system integration.

Technical Specifications

| Parameter | Details |

|---|---|

| Model Number | DSBC 176 |

| Part Number | 3BSE019216R1 |

| Product Type | Bus Extender Board |

| System Compatibility | Advant Controller 410, Advant Master DCS |

| Functionality | Backplane bus extension between main controller and submodules |

| Bus Type | ABB proprietary system bus (High-Speed) |

| Communication Mode | Passive signal extension with galvanic isolation |

| Power Supply | Powered via system backplane |

| Status Indicators | Yes (LED indicators for communication status) |

| Mounting Method | Rack-mounted (standard controller slot) |

| Hot Swap Capability | No |

| Operating Temperature | 0°C to +55°C |

| Storage Temperature | -40°C to +70°C |

| Humidity Tolerance | 5% to 95% RH, non-condensing |

| EMC Compliance | Meets industrial EMC standards |

| Dimensions (H × W × D) | 324 x 22.5 x 234 mm |

| Weight | 0.4 kg |

| Certifications | CE, UL, RoHS |

| Manufacturer | ABB Ltd. |

Applications

The DSBC 176 is engineered for extending bus communication within distributed or modular automation systems. It is commonly used in:

-

Power Generation: To extend controller bus to turbine interface boards or generator I/Os

-

Petrochemical Plants: Where control cabinets are separated by hazardous zones or long distances

-

Water and Waste Treatment: Facilitating extended I/O for geographically spread stations

-

Steel and Metal Processing: Connecting heat zone controllers and remote field interfaces

-

Substations and Switchgear Control: Used to extend control logic over segmented switch cabinets

-

Process Control Systems: Where redundancy and scalability demand physical distribution of logic boards

Product Advantages

-

Reliable Bus Extension: Seamless signal continuity across distributed system racks.

-

High-Speed Signal Transmission: Maintains timing precision for critical operations.

-

Compact and Lightweight: Slim form factor minimizes rack footprint while maximizing functionality.

-

LED Status Indicators: Allows easy visual diagnostics of operational status.

-

No External Wiring Needed: Draws power directly from system backplane for ease of deployment.

-

Industrial Durability: Engineered to withstand harsh conditions common in process industries.

-

Easy Integration: Plugs directly into ABB Advant system architecture.

-

Supports Scalable Architecture: Ideal for modular, expandable system layouts.

Frequently Asked Questions (FAQ)

1. How does the DSBC 176 improve system architecture in large-scale control environments?

The DSBC 176 allows for the physical separation of control modules across racks or enclosures while maintaining synchronized communication, enabling modular, scalable system design in industrial automation.

2. What are the benefits of using a dedicated bus extender board instead of long I/O cabling?

Using a bus extender like the DSBC 176 reduces signal degradation, electromagnetic interference, and latency issues commonly associated with long cable runs, while also simplifying maintenance and system segmentation.

3. Is the DSBC 176 suitable for upgrading existing Advant Controller 410 systems?

Yes, it is ideal for legacy system expansion, especially in cases where additional I/O racks or controller boards need to be added without major reconfiguration.

4. Can the DSBC 176 be used in high-vibration or harsh industrial environments?

The module is engineered with robust components and conforms to industrial environmental standards, making it reliable in high-vibration, high-temperature, or EMI-prone environments.

5. Does the DSBC 176 require firmware updates or configuration software?

No firmware updates or configurations are needed. It operates as a passive extender board with plug-and-play compatibility within ABB’s control system framework.

6. How does the DSBC 176 handle communication integrity across long distances?

It uses ABB’s proprietary high-speed backplane protocol with galvanic isolation to maintain data fidelity and synchronization even when extending the bus over multiple rack segments.

7. Are any special installation procedures required for grounding or shielding?

Proper system grounding is essential. ABB recommends following standard shielding and grounding practices to avoid cross-talk and maintain EMC compliance during installation.

8. What type of status indicators are available for monitoring module performance?

The DSBC 176 includes onboard LED indicators that provide real-time information about communication health and link status between extended racks.

9. Can multiple DSBC 176 boards be installed in a single system to support multiple rack extensions?

Yes, multiple bus extender boards can be integrated in larger systems as long as ABB’s system topology and signal integrity guidelines are followed.

10. How does DSBC 176 contribute to system reliability in redundant or mission-critical applications?

By ensuring consistent, isolated communication across distributed system modules, the DSBC 176 minimizes single points of failure and supports robust, fault-tolerant control architectures essential for mission-critical industries.

Related Models in the Same Series or Function Group

| Model Number | Description | Function | System | Weight (kg) |

|---|---|---|---|---|

| DSBC 173A | Bus Extender Module | Bus extension | Advant/Symphony | 0.35 |

| DSCA 125 | Communication Adapter Module | Interface/adapter | Symphony DCS | 0.36 |

| DSAI 130 | Analog Input Module | Sensor input module | Advant Master | 0.50 |

| DSDI 130 | Digital Input Module | Binary input module | Symphony | 0.48 |

| DSDO 120 | Digital Output Module | Digital output switching | Symphony | 0.47 |

| DSBC 176A | Updated Bus Extension Module | Extended signal bus version | Advant | 0.37 |

Popular ABB Modules Across Automation Platforms

| Model Number | Description | Function | System | Weight (kg) |

|---|---|---|---|---|

| PM864A | High-performance CPU Module | Controller | AC 800M | 1.5 |

| CI854A | PROFIBUS Communication Interface | Network Interface | AC 800M | 0.35 |

| AI810 | Analog Input Module (8 channels) | Analog signal processing | S800 I/O | 0.65 |

| DO810 | Digital Output Module (16 channels) | Field control output | S800 I/O | 0.27 |

| TB840A | I/O Bus Terminator | Bus termination | S800 I/O | 0.05 |

| CP6415 | 15” Human-Machine Interface Panel | Operator interface | CP600 Series | 3.2 |

Excellent PLC

Excellent PLC