| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

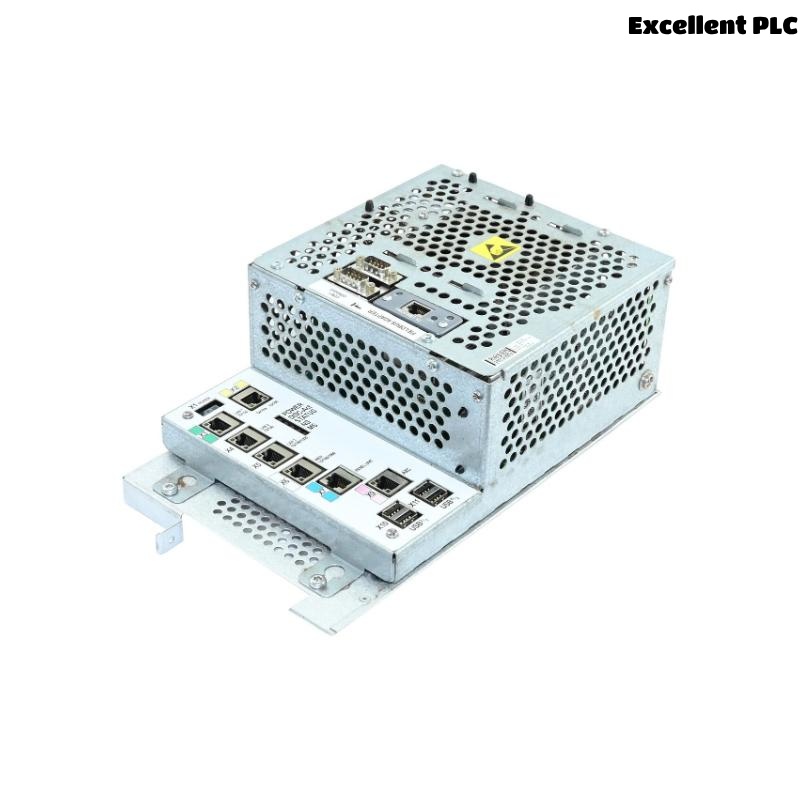

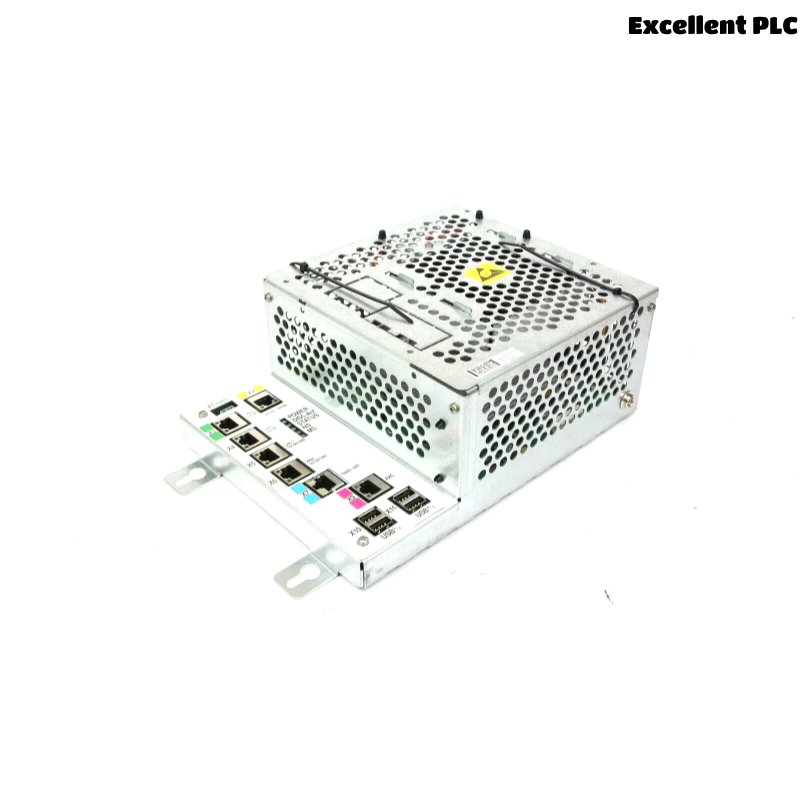

The ABB DSQC 1000 (3HAC042766-001) is a high-performance industrial I/O module designed for seamless integration with ABB’s robotic and automation systems. It serves as a reliable communication interface, enabling efficient signal processing and control in demanding industrial environments. This module is widely used in automotive, manufacturing, and logistics sectors due to its robustness, flexibility, and compatibility with ABB’s robotic controllers.

Product Parameters

| Parameter | Specification |

|---|---|

| Model Number | DSQC 1000 (3HAC042766-001) |

| Input Voltage | 24V DC (±10%) |

| Number of I/O | 16 Digital Inputs / 16 Digital Outputs |

| Communication | DeviceNet, Profibus (configurable) |

| Operating Temperature | 0°C to +55°C |

| Storage Temperature | -25°C to +70°C |

| Protection Rating | IP20 |

| Dimensions | 250 × 180 × 70mm |

| Weight | 1.86 kg |

| Mounting | DIN Rail or Panel Mount |

| Certifications | CE, UL, RoHS Compliant |

Product Applications

The ABB DSQC 1000 is widely used in industrial automation and robotics, including:

-

Automotive Manufacturing – Controls robotic arms for welding, painting, and assembly.

-

Material Handling – Manages conveyor systems and automated storage solutions.

-

Packaging Industry – Ensures precise control in filling, sealing, and labeling machines.

-

Electronics Assembly – Facilitates high-speed pick-and-place operations.

-

Metal & Machining – Integrates with CNC machines for automated part handling.

Product Advantages

-

High Reliability – Built for harsh industrial environments with strong resistance to electrical noise.

-

Easy Integration – Compatible with ABB robots and major fieldbus protocols (DeviceNet, Profibus).

-

Modular Design – Allows flexible expansion with additional I/O modules.

-

Fast Response Time – Ensures real-time signal processing for high-speed automation.

-

Durable Construction – Robust housing protects against dust and vibrations.

-

Simplified Maintenance – Hot-swappable design reduces downtime during replacements.

Frequently Asked Questions (FAQ)

-

What communication protocols does the DSQC 1000 support?

-

It supports DeviceNet and Profibus by default, with optional configurations for other protocols.

-

-

Can this module be used with non-ABB controllers?

-

Yes, but optimal performance is guaranteed with ABB robotic controllers.

-

-

What is the maximum cable length for signal connections?

-

Recommended max length is 30m for DeviceNet and 100m for Profibus (with proper shielding).

-

-

Is the DSQC 1000 waterproof?

-

No, it has an IP20 rating, meaning it is not waterproof and should be installed in a controlled environment.

-

-

How do I troubleshoot a faulty I/O channel?

-

Check the LED indicators on the module and verify wiring connections. Replace if diagnostics indicate hardware failure.

-

-

Can I expand the number of I/O points?

-

Yes, additional I/O modules can be daisy-chained via the communication bus.

-

-

What is the expected lifespan of this module?

-

Under normal conditions, it can operate reliably for 5+ years.

-

-

Does it require a separate power supply?

-

Yes, it operates on 24V DC, which must be supplied separately from the control system.

-

-

Is firmware upgradeable?

-

No, the DSQC 1000 operates on fixed firmware without upgrade options.

-

-

How long is the warranty period?

-

The standard warranty is 1 years, subject to proper usage and conditions.

Recommended Related & Popular Models

6 Related/Series Models

| Model Number | Description |

|---|---|

| DSQC 1001 | Enhanced I/O module with 32 digital channels |

| DSQC 1002 | Analog I/O module for precision control |

| DSQC 1003 | High-speed counter module for encoders |

| DSQC 1004 | Mixed I/O module (digital + analog) |

| DSQC 1005 | Safety-rated I/O module for robot cells |

| DSQC 1006 | Ethernet/IP communication module |

6 Popular ABB Models

| Model Number | Description |

|---|---|

| IRB 6700 | High-payload industrial robot series |

| IRB 2600 | Compact robot for precision tasks |

| ACS880 | Industrial drive for motor control |

| CP635 | HMI panel for automation control |

| S800 I/O | Modular I/O system for process automation |

| Yumi IRB 14000 | Collaborative dual-arm robot |

Excellent PLC

Excellent PLC