| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

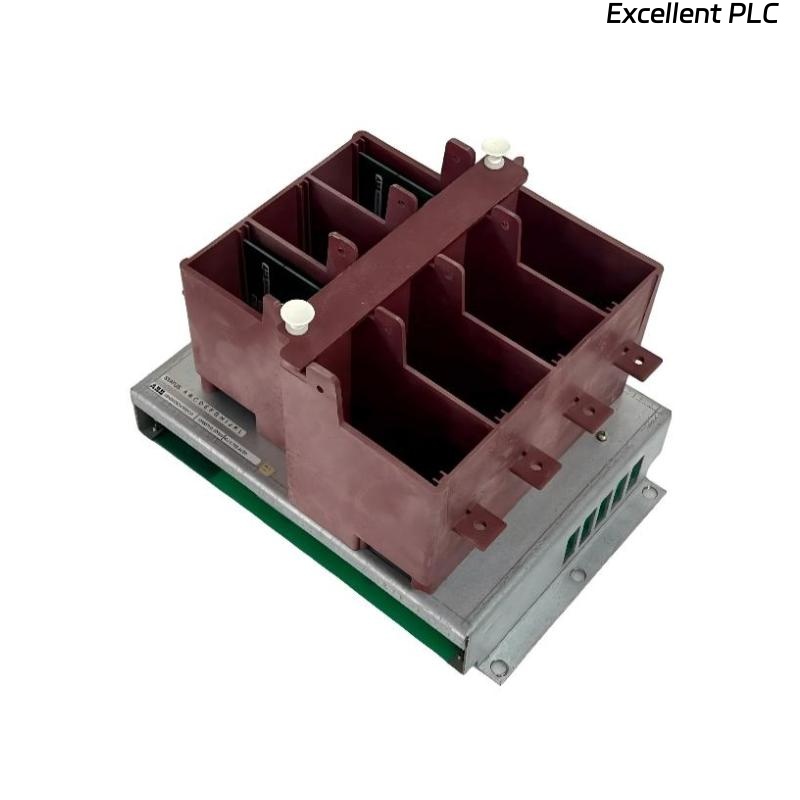

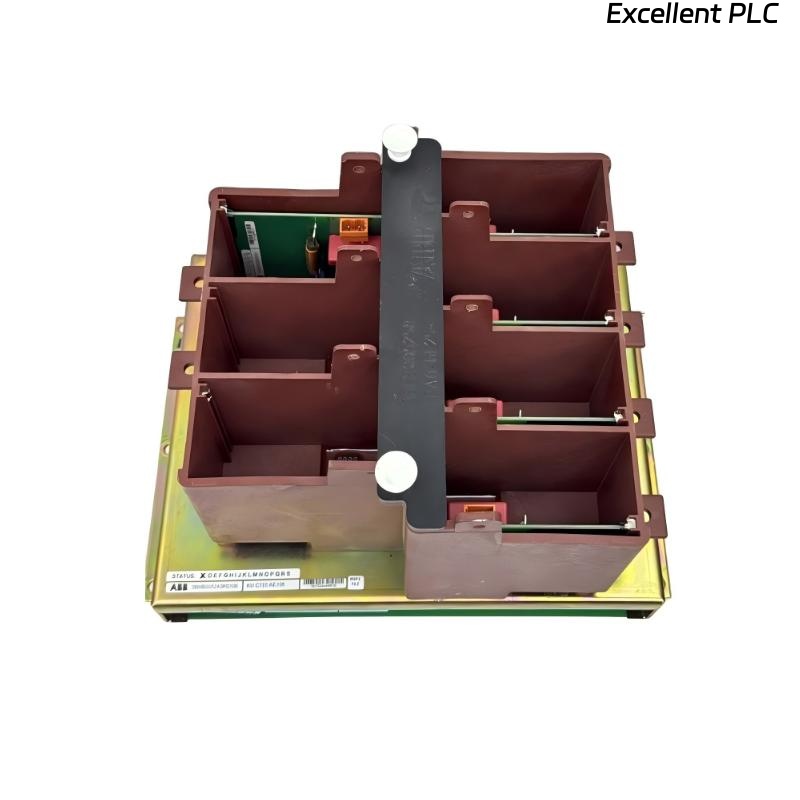

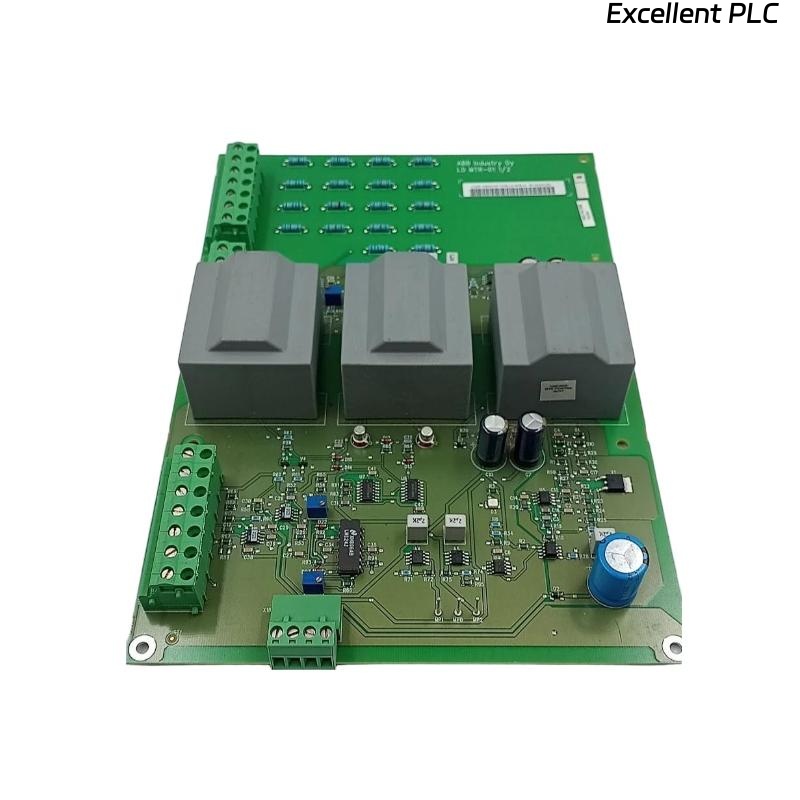

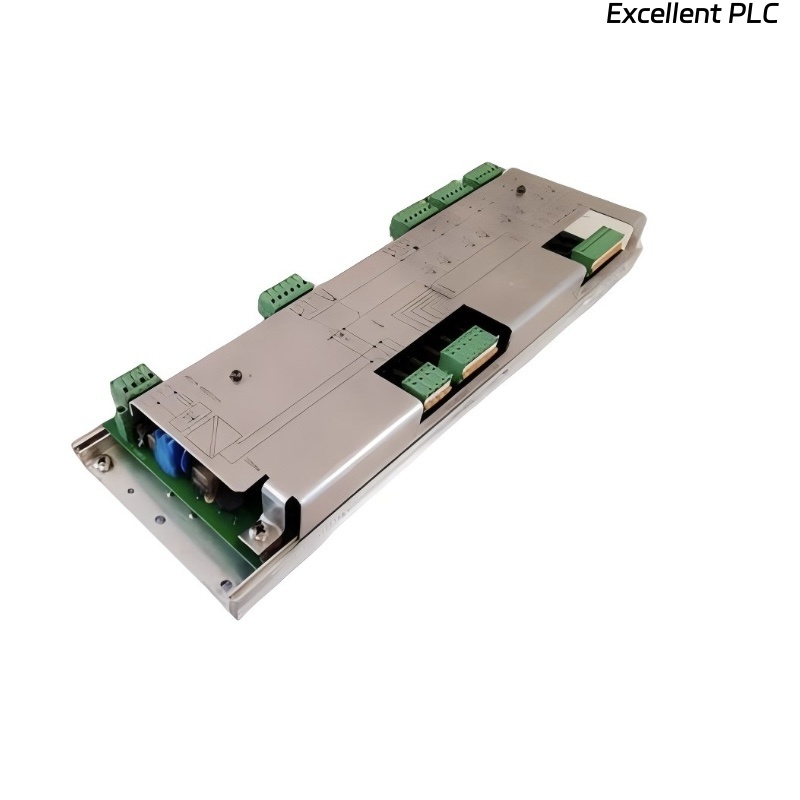

The ABB DSQC 406 (3HAC035301-001) is a high-performance drive unit developed by ABB for integration with its robotic systems, particularly within the IRB robot series. This drive unit plays a critical role in the precision control of motors, facilitating the accurate and synchronized movement required in industrial automation applications.

The DSQC 406 is recognized for its reliability, modular design, and integration efficiency, making it a staple component in many production environments. It operates as part of the motion control system in ABB robots, where it communicates with the robot controller to execute precise movements and speed adjustments for servo motors.

Technical Specifications

| Parameter | Specification |

|---|---|

| Model Number | DSQC 406 |

| Part Number | 3HAC035301-001 |

| Brand | ABB |

| Function | Drive Unit for servo control |

| Compatible Systems | IRB industrial robots |

| Voltage Input | 24V DC (control), 3-phase AC (power) |

| Communication Interface | RS-232 / CAN / proprietary ABB bus |

| Cooling Method | Forced air / passive, depending on installation |

| Dimensions (L × W × H) | 335 x 288 x 169.5 mm |

| Weight | 7.82 kg |

| Mounting Type | Panel-mounted |

| Enclosure Rating | IP20 (depending on integration) |

| Operating Temperature | 0°C to +45°C |

| Storage Temperature | -25°C to +70°C |

| Relative Humidity | 5% to 95% (non-condensing) |

| Compliance Standards | CE, RoHS, ISO9001 |

Applications

The DSQC 406 Drive Unit is widely used across multiple industrial domains due to its versatility and performance. Key applications include:

-

Automotive Manufacturing: Ensures accurate welding, painting, and part assembly using robotic arms.

-

Electronics Assembly: Controls robotic systems that handle precise placement of components.

-

Food and Beverage Automation: Supports hygienic, high-speed packaging and sorting operations.

-

Material Handling: Controls robotic pick-and-place operations and conveyor systems.

-

Metal Fabrication: Drives robotic tools for cutting, welding, and forming metal components.

Product Advantages

-

High Precision Motor Control: Delivers consistent and accurate motor operation, ensuring optimal robot movement.

-

Robust and Durable Design: Engineered to perform under continuous industrial conditions.

-

Seamless Integration: Designed to integrate effortlessly with ABB robotic controllers and feedback systems.

-

Low Maintenance: With fewer moving parts and self-diagnostic features, operational downtime is minimized.

-

Energy Efficient: Optimized power usage contributes to reduced operational costs.

-

Proven Reliability: Extensively tested and proven in real-world industrial environments for long-term reliability.

Frequently Asked Questions (FAQ)

-

How does the DSQC 406 drive unit contribute to robot performance?

The DSQC 406 ensures smooth and accurate control of servo motors, which directly translates into precise robot movement and higher task repeatability in automation applications. -

Can this drive unit be replaced in the field without special tools?

Yes, the DSQC 406 is designed for easy swap-out in industrial environments. It uses standard mounting and connection interfaces, so most maintenance teams can handle the replacement with minimal downtime. -

Is the DSQC 406 only suitable for ABB robots, or can it be used in custom systems?

While optimized for ABB IRB robots, some integrators may incorporate it into custom systems. However, using it outside ABB’s ecosystem may require significant configuration and is not typically supported. -

How does the DSQC 406 handle overload or power surges?

It includes built-in protection features that monitor voltage, current, and thermal conditions. In case of abnormal power events, it safely shuts down to prevent component damage. -

What’s the expected operational lifespan of this unit?

With proper installation and usage within rated conditions, the DSQC 406 can operate reliably for over 10 years. Many units in the field have exceeded this under routine preventive maintenance. -

Can the DSQC 406 be configured for multiple motor types?

It supports a range of ABB-approved motors. Configuration is handled via the main robot controller, which communicates the necessary parameters to the drive unit. -

What kind of diagnostics does this unit provide?

It features status LEDs and transmits error codes to the robot controller. These diagnostics assist technicians in quickly identifying wiring faults, overloads, or internal errors. -

How does the unit dissipate heat during operation?

It relies on passive heat sinking and forced-air ventilation, depending on system setup. Ensuring adequate airflow around the unit helps maintain safe operating temperatures. -

Are software or firmware updates required for this drive?

Typically, the DSQC 406 does not require frequent firmware updates. If updates are released by ABB, they are usually applied via the central control system during routine service. -

What certifications does this drive meet for global industrial use?

It conforms to CE and RoHS standards and is manufactured under ISO 9001-certified processes, ensuring compliance with international safety and environmental regulations.

Related Models (Same Series or Functionality)

| Model | Function | Key Specs |

|---|---|---|

| DSQC 452 | Servo drive interface | Multi-axis, CAN bus |

| DSQC 663 | Servo drive module | For advanced robotic applications |

| DSQC 679 | Drive Control Unit | Modular, high current output |

| DSQC 663 3HAC14551-2 | Advanced Motion Control Unit | For newer ABB IRB robots |

| DSQC 604 | Motor control board | Simplified interface for motor output |

| DSQC 500 | General Drive Interface | Robust, reliable control module |

Popular ABB Industrial Models

| Model | Product Type | Application |

|---|---|---|

| IRC5 | Robot Controller | All-purpose robot control system |

| ACS880 | Variable Frequency Drive | Industrial motor control |

| DSQC 652 | IO Expansion Module | Digital input/output signal control |

| PM864AK01 | CPU Module (AC 800M) | Process automation systems |

| CP600 Series HMI | Human-Machine Interface | Industrial visualization and control |

| S800 I/O | Modular IO system | Distributed process control |

Excellent PLC

Excellent PLC