| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Overview

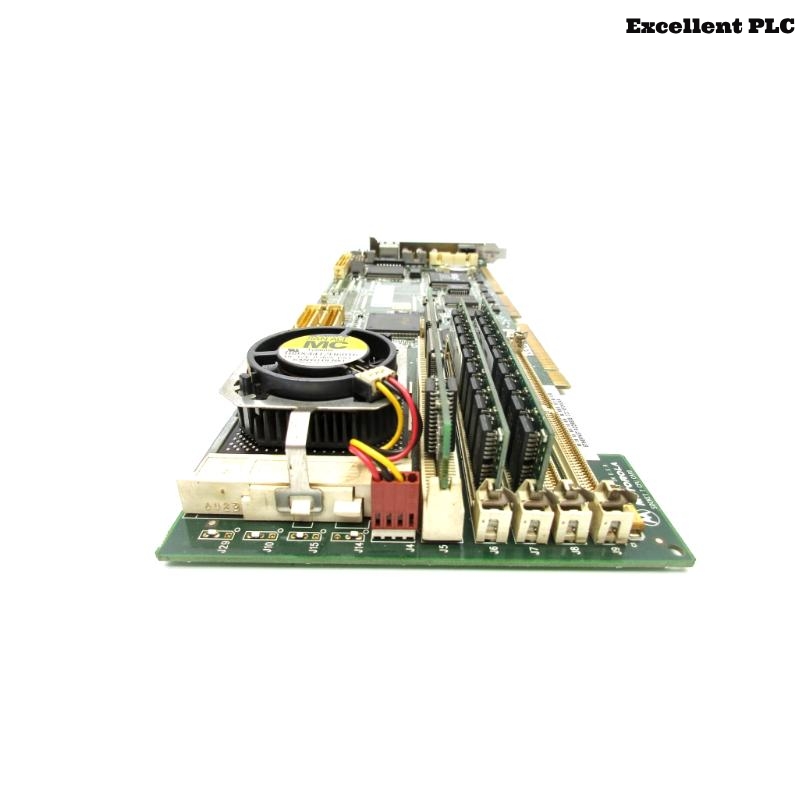

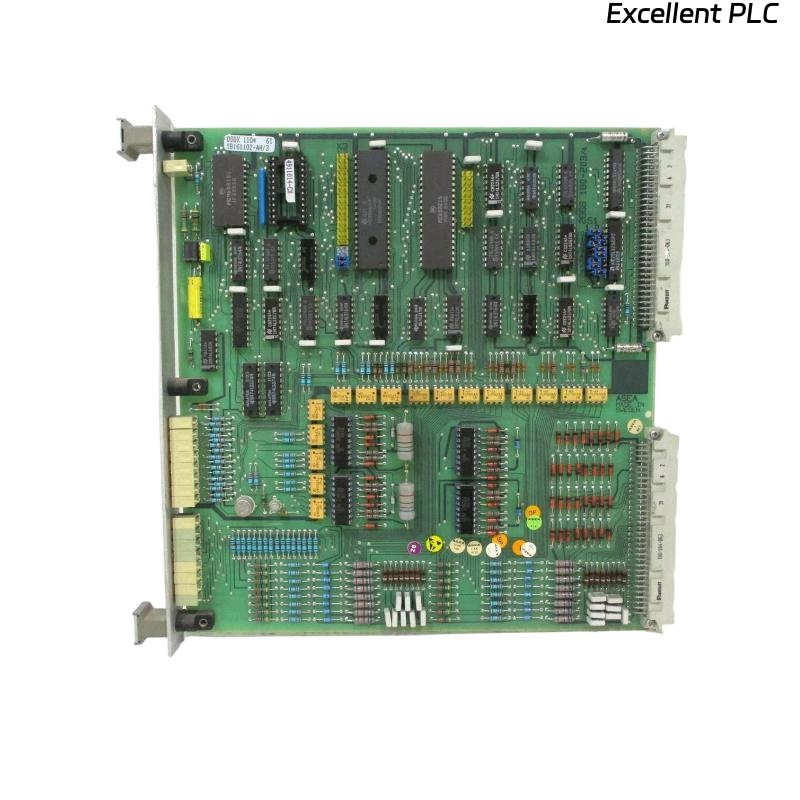

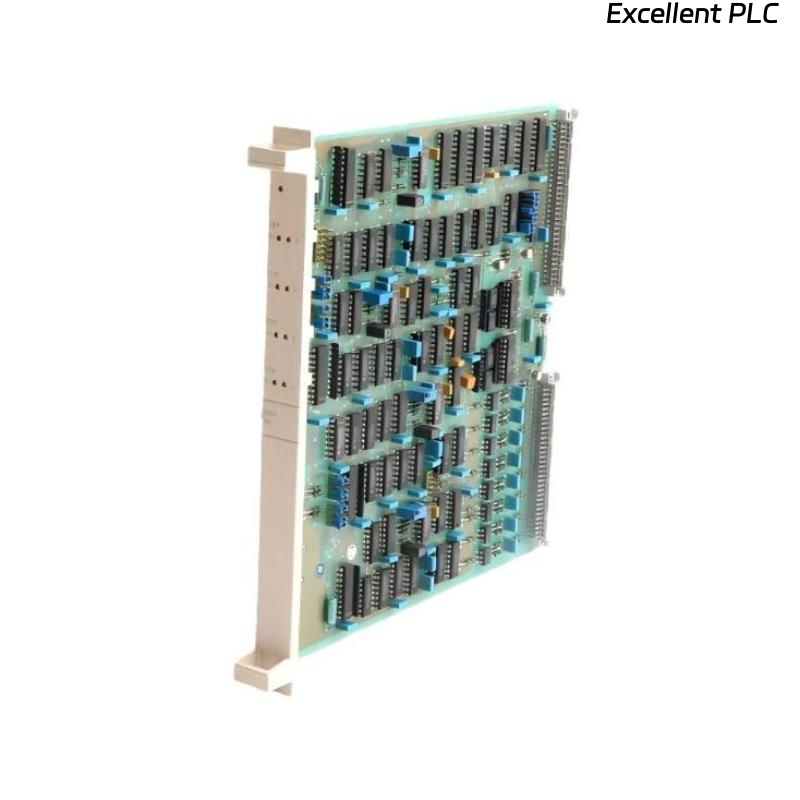

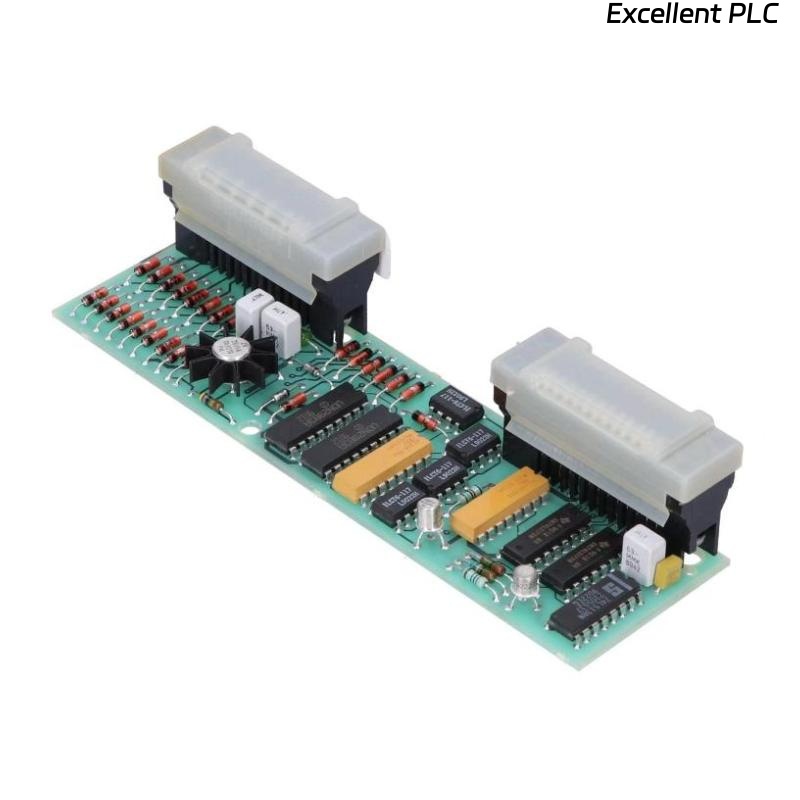

The DSQC 500 Main Computer Controller is designed to manage complex robotic tasks with precision and reliability. It processes real-time data, executes control algorithms, and communicates with other system components to facilitate coordinated movements and operations. Its robust architecture ensures consistent performance in demanding industrial environments.

Technical Specifications

| Parameter | Specification |

|---|---|

| Model Number | DSQC 500 (3HAC3616-1) |

| Dimensions (L×W×H) | 400 x 200 x 100 mm |

| Weight | 0.97 kg |

| Processor | Embedded Industrial CPU |

| Memory | 64 MB RAM |

| Storage | 128 MB Flash Memory |

| Communication Ports | Ethernet, RS-232, CAN |

| Operating Temperature | 0°C to +55°C |

| Storage Temperature | -25°C to +70°C |

| Humidity Range | 5% to 95% (non-condensing) |

| Power Supply | 24 V DC |

| Compliance | CE, UL, RoHS |

Applications

The DSQC 500 is utilized across various industries, including:

-

Automotive Manufacturing: For tasks such as welding, painting, and assembly.

-

Electronics: Precision handling and assembly of components.

-

Pharmaceuticals: Handling delicate processes requiring high precision.

-

Food and Beverage: Packaging and palletizing operations.

-

Metal Fabrication: Cutting, welding, and material handling.

Advantages

-

High Reliability: Engineered for continuous operation in industrial settings.

-

Scalability: Compatible with various ABB robotic systems, allowing for flexible integration.

-

Ease of Maintenance: Modular design facilitates quick replacements and upgrades.

-

Robust Communication: Multiple ports ensure seamless connectivity with peripherals.

-

Energy Efficiency: Optimized power consumption for sustainable operations.

Frequently Asked Questions (FAQ)

1.Is the DSQC 500 suitable for retrofitting older ABB robotic systems?

– Yes, it’s particularly effective for upgrading legacy S4C and S4C+ systems, maintaining compatibility without needing a full system overhaul.

2.What kind of real-time tasks can the DSQC 500 handle?

– It processes trajectory planning, motion control, I/O coordination, and safety monitoring in real time, ensuring smooth and accurate robotic movements.

3.What happens if the DSQC 500 fails during operation?

– In case of failure, ABB’s system architecture allows for quick fault diagnosis and rapid replacement, minimizing production downtime.

4.Can the DSQC 500 be used in a multi-robot setup?

– Absolutely. It supports synchronization and coordination across multiple robots when configured properly with ABB’s controller network.

5.How is this controller typically maintained in a production environment?

– Maintenance involves regular diagnostics checks via ABB tools, inspection of communication integrity, and environmental condition monitoring.

6.Does the DSQC 500 support integration with modern SCADA systems?

– Yes, it can communicate with SCADA and MES systems via standard industrial protocols like Ethernet/IP and Modbus TCP.

7.Are there any known compatibility limitations with newer ABB control interfaces?

– While optimized for S4C and S4C+, it may require interface adapters or firmware tuning to work with newer generations of ABB controllers.

8.What are common signs that the DSQC 500 may need replacement?

– Frequent communication errors, random restarts, and failure to initialize robot axes are typical signs indicating potential hardware degradation.

9.Is software licensing required to configure or operate the DSQC 500?

– Configuration tools like RobotStudio may require a license, but basic diagnostics and updates can often be performed without additional costs.

10.How long is the average service life of a DSQC 500 in normal industrial use?

– Under standard operating conditions, the DSQC 500 typically offers 8–12 years of stable performance before major servicing is needed.

Related Models

| Model Number | Description |

|---|---|

| DSQC 501 | Enhanced version with additional ports |

| DSQC 502 | Compact variant for smaller systems |

| DSQC 503 | High-speed processing capabilities |

| DSQC 504 | Integrated with advanced diagnostics |

| DSQC 505 | Extended memory capacity |

| DSQC 506 | Designed for harsh environmental conditions |

Popular ABB Models

| Model Number | Description |

|---|---|

| AC 800M | Modular process controller for complex applications |

| PM 864A | High-performance CPU module |

| PM 891 | Advanced controller with extended features |

| AC 500 | Scalable PLC for diverse automation needs |

| PM 865 | Safety-certified controller for critical operations |

| PM 866 | Redundant CPU module for high availability |

Excellent PLC

Excellent PLC