| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

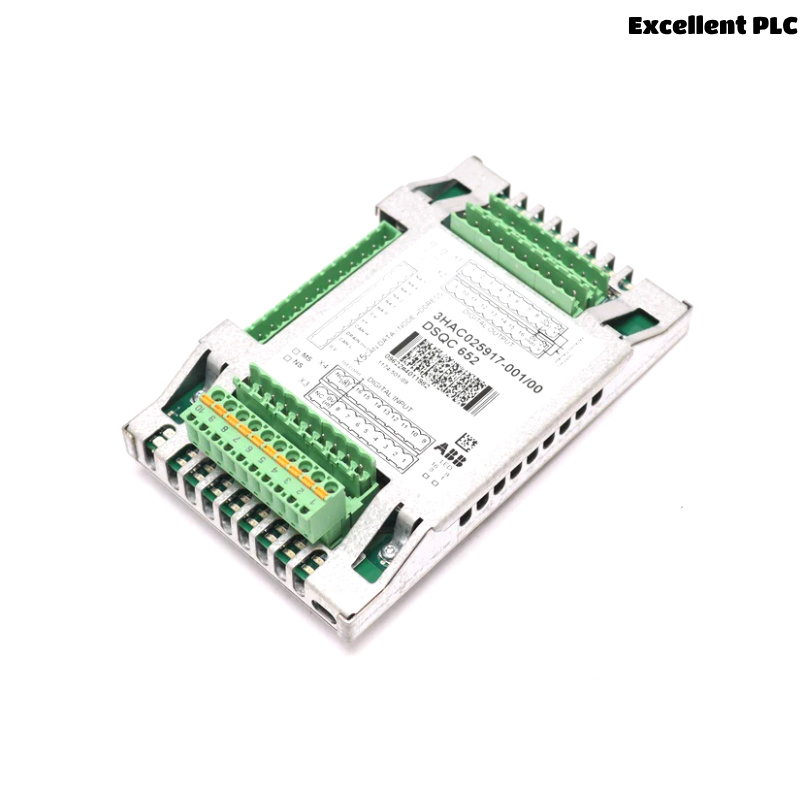

The ABB DSQC 652 3HAC025917-001 is a high-performance I/O module designed for industrial automation and robotic systems. It is part of ABB’s extensive range of control products, specifically engineered for seamless integration with ABB robots and other industrial equipment. This module ensures reliable signal processing, real-time communication, and robust performance in demanding environments.

Product Specifications

| Parameter | Details |

|---|---|

| Model Number | DSQC 652 3HAC025917-001 |

| Input Voltage | 24V DC (±10%) |

| Number of Inputs | 16 digital inputs |

| Number of Outputs | 16 digital outputs |

| Communication | DeviceNet protocol |

| Operating Temp. | 0°C to +55°C (32°F to 131°F) |

| Storage Temp. | -25°C to +70°C (-13°F to 158°F) |

| Humidity Range | 5% to 95% (non-condensing) |

| Dimensions | 155.5x 98.5x 41.3 mm |

| Weight | 0.38 kg |

| Protection Class | IP20 |

| Mounting | DIN rail or panel mounting |

| Certifications | CE, UL, RoHS compliant |

Product Applications

The DSQC 652 is widely used in industrial automation, particularly in robotic systems for:

-

Material Handling – Enables precise control of conveyors and grippers.

-

Assembly Lines – Facilitates synchronized operations in automotive and electronics manufacturing.

-

Welding & Painting – Ensures accurate signal transmission for robotic welding and spray applications.

-

Packaging Systems – Integrates with PLCs to manage sorting and packaging tasks.

-

Machine Tending – Supports automated loading/unloading of CNC machines.

Product Advantages

-

High Reliability – Built for 24/7 operation in harsh industrial environments.

-

Fast Response Time – Optimized for real-time control applications.

-

Easy Integration – Compatible with ABB robots and third-party systems via DeviceNet.

-

Compact Design – Space-saving form factor for flexible installation.

-

Durable Construction – Resistant to electrical noise and vibrations.

-

Plug-and-Play Setup – Simplifies installation and reduces downtime.

Frequently Asked Questions (FAQ)

Q1: What communication protocol does the DSQC 652 support?

A1: It uses DeviceNet, a widely adopted industrial network protocol.

Q2: Can this module be used with non-ABB robots?

A2: Yes, it is compatible with any DeviceNet-supported system.

Q3: What is the maximum input/output current?

A3: Each channel supports up to 500 mA for inputs and outputs.

Q4: Is the DSQC 652 hot-swappable?

A4: No, it requires power cycling for safe replacement.

Q5: What is the lifespan of this module?

A5: Designed for 100,000+ operational hours under normal conditions.

Q6: Does it support analog signals?

A6: No, it is a digital-only I/O module.

Q7: Can it operate in high-vibration environments?

A7: Yes, it is built to withstand industrial vibrations.

Q8: What is the warranty period?

A8: Typically 12 months, depending on the supplier.

Q9: Are there LED indicators for status monitoring?

A9: Yes, it includes diagnostic LEDs for power and I/O status.

Q10: How do I troubleshoot communication errors?

A10: Check DeviceNet cabling, node addressing, and termination resistors.

Recommended Related Models

| Model Number | Description |

|---|---|

| DSQC 651 | 8-input/8-output digital module |

| DSQC 653 | 32-input digital module |

| DSQC 654 | 16-input/16-output, Profibus version |

| DSQC 328A | Compact I/O module for IRC5 controllers |

| DSQC 1000 | Advanced Ethernet/IP communication module |

| DSQC 1030 | High-density I/O module for large systems |

Popular ABB Models in the Same Brand

| Model Number | Description |

|---|---|

| IRB 2600 | High-precision industrial robot |

| IRB 6700 | Heavy-duty robot for material handling |

| ACS880 | Industrial drive for motor control |

| PM864AK01 | Advanced process controller |

| CP635 | Panel-mounted HMI for automation |

| S800 I/O | Modular I/O system for process control |

Excellent PLC

Excellent PLC