| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

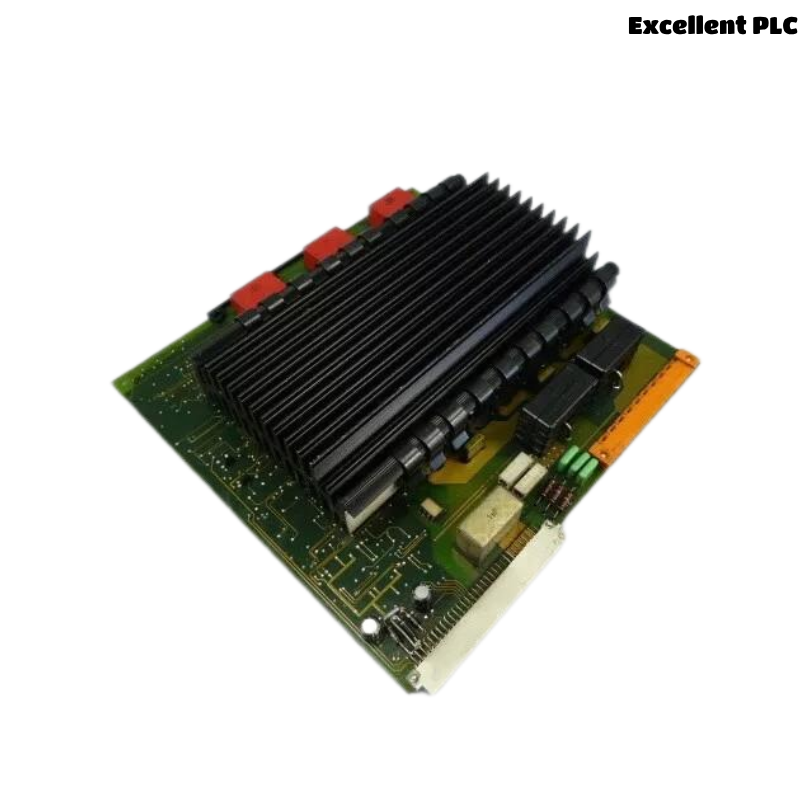

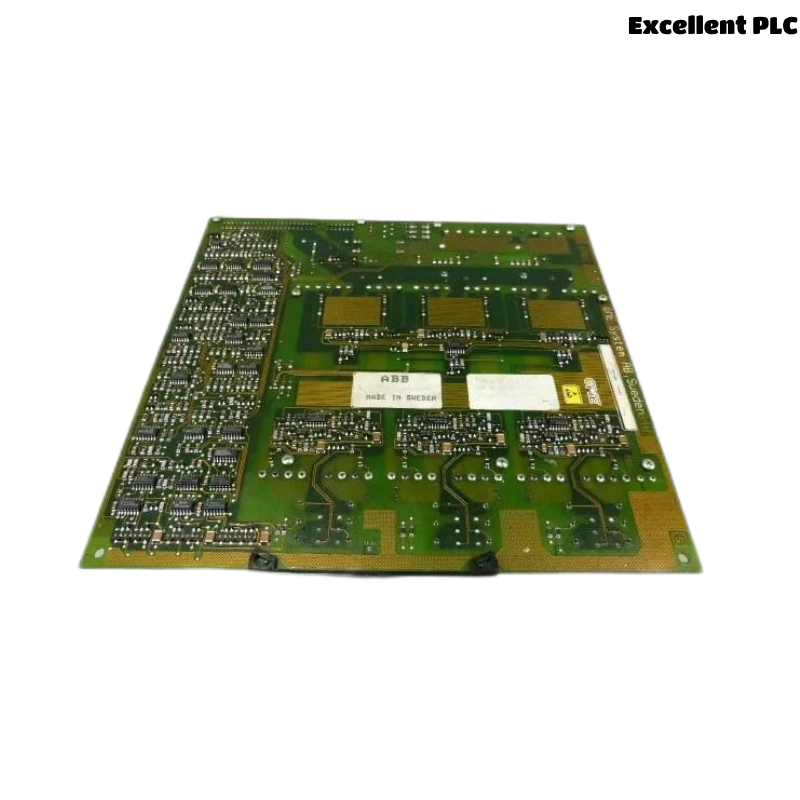

Product Overview

The ABB DSQC236T (YB560103-CE) is a high-performance Servo Drive Control Board designed to provide precise control and coordination of servo motors within ABB’s industrial automation and robotics systems. This control board is a critical component in the servo drive architecture, responsible for executing complex motion control algorithms, managing motor feedback, and ensuring smooth and accurate positioning for robotic arms and automated machinery.

The DSQC236T is engineered for robust operation under demanding industrial conditions, supporting ABB’s motion control requirements with high reliability, flexibility, and scalability. It plays an integral role in optimizing productivity and precision in applications such as robotic welding, assembly, and material handling.

Key Features

-

Advanced servo drive control for ABB robotics and automation systems

-

Supports closed-loop feedback control with high precision

-

Real-time processing capability for smooth and accurate motor movements

-

Compact PCB design suitable for integration within servo drive enclosures

-

High tolerance to electrical noise and industrial interference

-

Compatibility with ABB’s range of servo motors and drives

-

Diagnostic and fault detection functions for enhanced system reliability

-

Firmware upgradeable for future feature enhancements

-

Designed to meet industrial standards for robustness and safety

Technical Specifications

| Specification | Details |

|---|---|

| Product Name | Servo Drive Control Board |

| Model Number | DSQC236T (YB560103-CE) |

| Function | Control of servo motor drives |

| Supported Motors | ABB servo motors (various models) |

| Control Method | Closed-loop position, velocity, and torque control |

| Processor Type | High-speed embedded microcontroller |

| Communication Interfaces | Fieldbus, Ethernet, and proprietary interfaces (depending on system) |

| Input Voltage | Typically 24 V DC (logic/control power) |

| Operating Temperature | 0°C to 55°C |

| Storage Temperature | -40°C to 70°C |

| Dimensions | 120 x 80 x 40mm |

| Weight | 0.5 kg |

| Mounting | PCB board mount inside servo drive enclosure |

| Diagnostic Features | Fault detection, error logging, status LEDs |

| Certifications | CE, UL, RoHS compliant |

| Firmware | Upgradeable via dedicated programming tools |

Industry Applications

The DSQC236T Servo Drive Control Board is used in a wide range of ABB servo motor-driven applications including:

-

Industrial Robotics: Precise joint and axis control in robotic arms

-

Automotive Manufacturing: Robotic welding, painting, and assembly operations

-

Packaging: High-speed and accurate servo motion for packing lines

-

Material Handling: Conveyors, pick-and-place systems, and automated storage

-

Textile Machinery: Fine control of servo motors in weaving and knitting equipment

-

Machine Tools: CNC machining centers requiring precise axis control

Product Advantages

-

High precision servo control enables smooth and accurate motor operation

-

Robust design ensures long-term reliability in harsh industrial environments

-

Compact size facilitates integration into existing servo drive systems

-

Comprehensive diagnostics allow for quick fault identification and system troubleshooting

-

Firmware upgrade capability supports evolving automation requirements

-

Compatibility with a broad range of ABB servo motors and controllers

-

Improved noise immunity enhances signal integrity and control stability

-

Optimized for industrial safety and compliance standards

Frequently Asked Questions (FAQ)

1. What is the function of the DSQC236T control board?

It manages servo motor control, including position, velocity, and torque in ABB servo drive systems.

2. Which servo motors are compatible with this board?

It supports various ABB servo motors designed for industrial automation.

3. Can the firmware be upgraded?

Yes, the firmware is upgradeable using ABB’s dedicated programming tools.

4. What operating temperature range does it support?

It operates between 0°C and 55°C.

5. Does the board include diagnostic features?

Yes, it has fault detection, error logging, and status indicator LEDs.

6. How is the board mounted?

It is mounted inside the servo drive enclosure as a printed circuit board (PCB).

7. What communication interfaces does it support?

It supports Fieldbus, Ethernet, and proprietary ABB communication protocols depending on system design.

8. Is it compliant with industry safety standards?

Yes, it meets CE, UL, and RoHS compliance requirements.

9. What is the power supply requirement?

The board typically uses 24 V DC for logic and control power.

10. Can it be used in harsh industrial environments?

Yes, it is designed for robust operation with high noise immunity and industrial-grade components.

Related ABB Servo Drive and Control Boards

| Model | Description |

|---|---|

| DSQC236 | Earlier version of servo drive control board |

| DSQC247 | Advanced servo control board with extended features |

| DSQC238 | Motion control board for ABB servo drives |

| DSQC502 | High-performance servo controller module |

| DSQC247A | Enhanced version of DSQC247 with improved diagnostics |

| DSQC385 | Interface board for servo drive communication |

Popular ABB Automation Components

| Model | Description |

|---|---|

| ACS880 | ABB’s modular variable frequency drive (VFD) |

| IRC5 | ABB robot controller platform |

| IRB 2600 | Medium-payload industrial robot |

| DSQC305 | Robot power supply module |

| PM563 | ABB PLC with motion control capabilities |

| AC500 | ABB’s automation controller series |

Excellent PLC

Excellent PLC