| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Overview

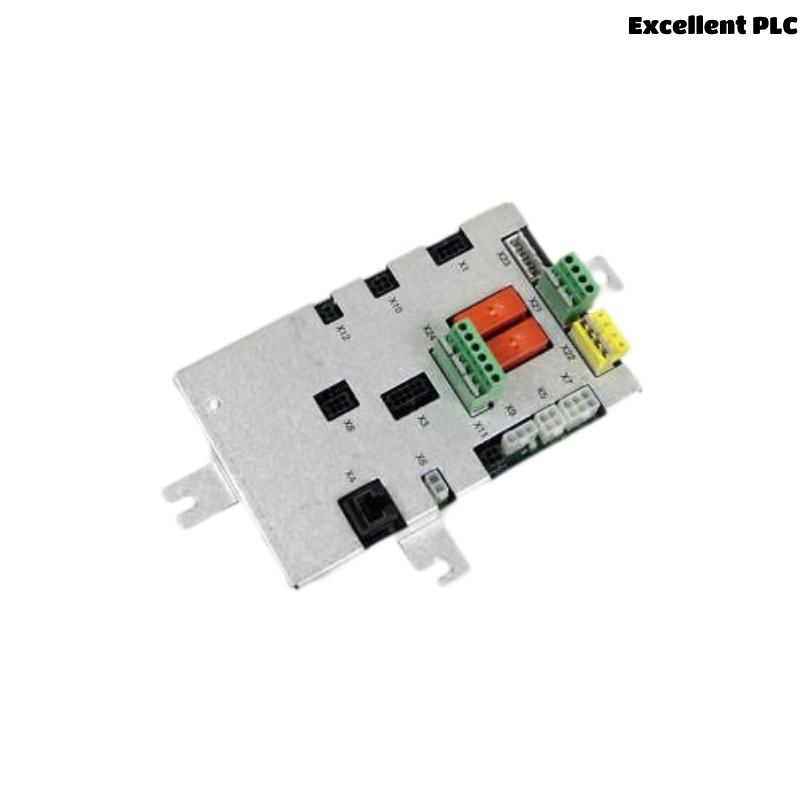

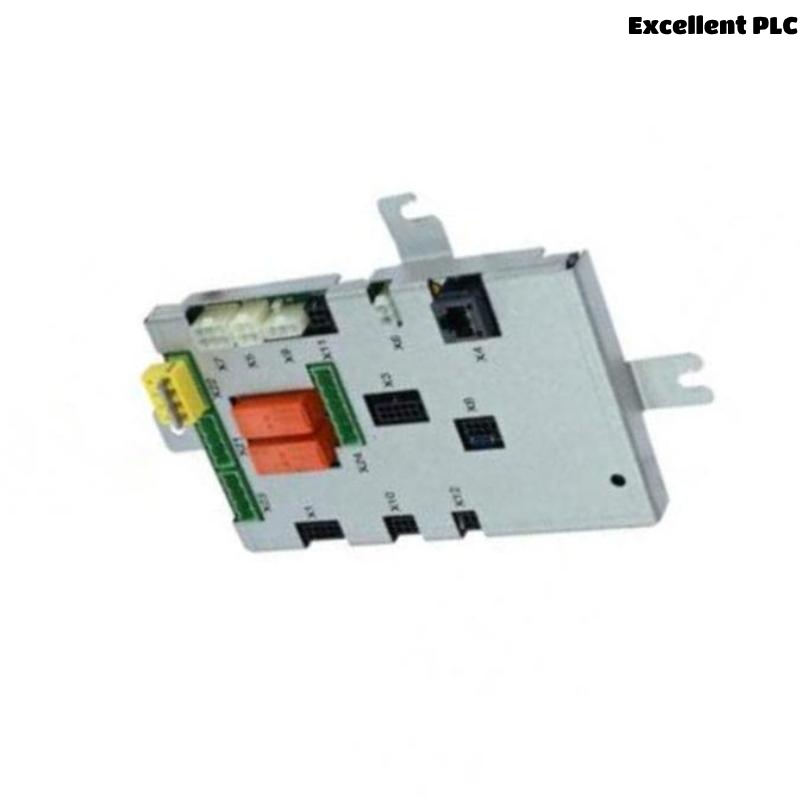

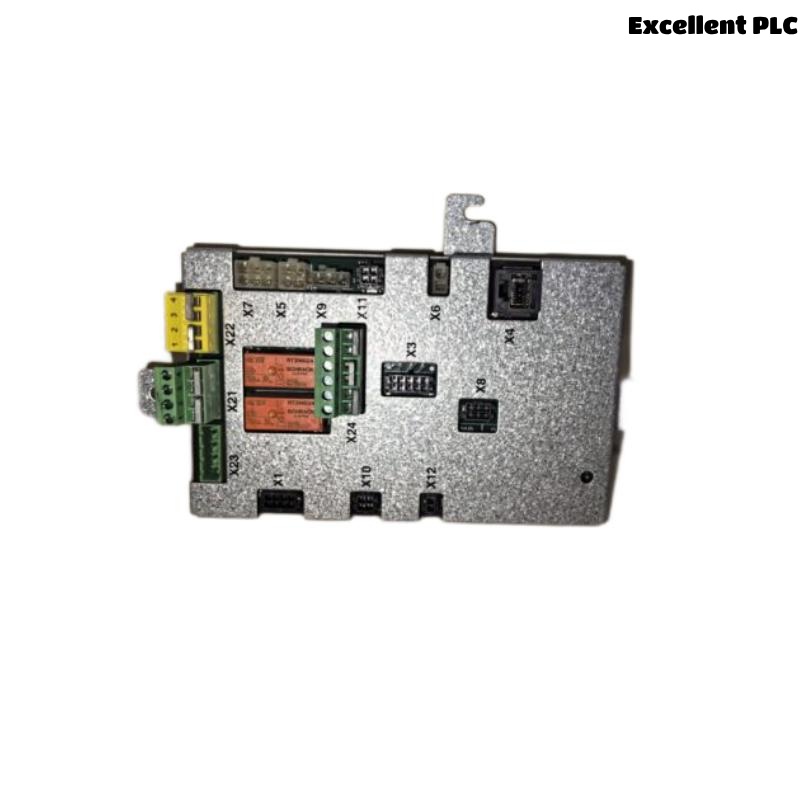

The ABB DSQC611 3HAC13389-2 is a contactor unit designed for integration with ABB robotic systems, particularly within the IRB series robots. It functions as a key electrical interface for power switching, safety circuit control, and interlocking mechanisms within robot control cabinets.

Engineered for industrial-grade reliability and performance, the DSQC611 provides high-speed contactor operations for main power line switching and safe power-off handling. It supports robotic applications that require frequent and rapid contactor operation, and integrates seamlessly with ABB robot controllers like IRC5, enabling precise coordination between logic control and power circuitry.

This unit ensures safe disconnection of power under fault conditions and serves as a critical element in robot safety chains.

Key Features

-

Robust electromechanical contactor for robotic power switching

-

Designed specifically for ABB industrial robot systems

-

Integrated with safety interlock circuits for fail-safe operation

-

Interfaces directly with IRC5 robot controllers

-

High mechanical and electrical endurance

-

Rapid switching with arc suppression for long lifecycle

-

DIN rail or panel mountable within the robot control cabinet

-

Includes terminals for status feedback and control signal wiring

-

Designed to meet industrial safety and electromagnetic compatibility standards

Technical Specifications

| Specification | Details |

|---|---|

| Product Type | Contactor Unit |

| Model Number | DSQC611 |

| Part Number | 3HAC13389-2 |

| Application | Power switching in ABB robot control systems |

| Rated Voltage | 24 VDC (control), 400/480 VAC (main contacts, typical) |

| Rated Current | Approx. 25 A – 40 A (depending on specific load configuration) |

| Control Signal Type | Digital (24 VDC control logic from controller) |

| Contact Configuration | Normally Open (NO) |

| Auxiliary Contacts | Yes (for status feedback) |

| Switching Frequency | High-cycle, robotic operation-ready |

| Mounting | DIN rail or panel mount |

| Protection Class | IP20 (as standard; higher when cabinet-installed) |

| Compliance | CE, UL, CSA, RoHS |

| Operating Temperature | 0°C to +55°C |

| Storage Temperature | -25°C to +70°C |

| Humidity | 5% to 95%, non-condensing |

| Dimensions | 160 x 10 x 27.1mm |

| Weight | 0.14 kg |

Industry Applications

The DSQC611 3HAC13389-2 is widely utilized in industrial robotics and factory automation, especially where precise power control is essential for robot safety and operation. Applications include:

-

Automotive Manufacturing – Robotic welding, assembly, and painting cells

-

Electronics and Semiconductors – Precision assembly and packaging lines

-

Food and Beverage – Robotic pick-and-place and packaging systems

-

Aerospace – Composite part handling and fastener automation

-

General Industrial Automation – CNC machine tending, material handling

Product Advantages

-

Factory-calibrated for ABB robots, ensuring perfect compatibility

-

High reliability with long mechanical and electrical lifespan

-

Facilitates safe, controlled power shutdowns for robotic systems

-

Reduces maintenance needs due to arc-resistant contact design

-

Integrated status feedback enables fault detection and diagnostics

-

Compact footprint simplifies control cabinet integration

-

Meets global safety standards, essential for automation compliance

-

Proven performance in high-cycle robotic environments

Frequently Asked Questions (FAQ)

1. What is the DSQC611 used for?

It is a contactor unit used to switch power on/off within ABB robot control cabinets, particularly in IRC5-based systems.

2. Is it compatible with all ABB robots?

It is designed for IRB series robots and IRC5 controllers, but specific compatibility should be verified with ABB documentation.

3. Does this unit include auxiliary contacts?

Yes, the DSQC611 includes auxiliary contacts for providing feedback to the control logic.

4. Can I replace this unit while the system is powered on?

No. Power must be disconnected before replacing or servicing the unit.

5. What kind of power does it switch?

It switches AC main power (e.g., 400–480 VAC) using 24 VDC control signals.

6. Is it part of the robot’s safety circuit?

Yes. It is integrated into safety chains, ensuring safe system behavior during faults.

7. What are its mechanical and electrical endurance ratings?

It is designed for high switching cycles, suitable for robotic applications with frequent power cycling.

8. Can it be used in third-party systems?

While possible, it is optimized for ABB systems, and its full functionality is guaranteed only in such contexts.

9. Is it easy to install?

Yes, it supports DIN rail or panel mounting and features labeled terminals for quick wiring.

10. Where is this unit located in the system?

It is typically installed inside the robot control cabinet, near the main power relay section.

Related ABB Robotic System Components

| Model | Description |

|---|---|

| DSQC679 | Safety Relay Board for robot controller |

| DSQC504 | Axis Computer Module for IRC5 |

| DSQC608 | Power Supply Board for robot system |

| DSQC652 | Servo Drive Unit for robotic axes |

| DSQC663 | I/O Communication Board |

| DSQC679B | Enhanced Safety Relay Unit for robots |

Popular ABB Robotics and Automation Modules

| Model | Description |

|---|---|

| IRC5 | ABB’s fifth-generation robot controller system |

| DSQC679 | Safety relay module for emergency stop functions |

| DSQC652 | High-performance servo drive unit |

| DSQC663 | I/O Communication Interface Module |

| DSQC504 | Axis computer/controller for robotic motion |

| DSQC636 | Power distribution module |

Excellent PLC

Excellent PLC