| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

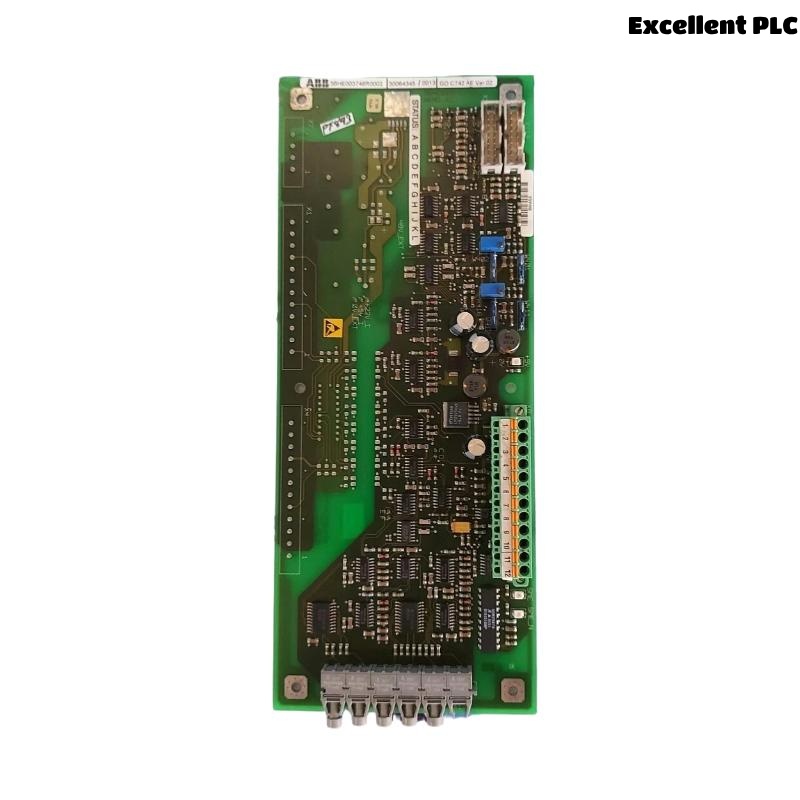

The ABB GD C742 AE 3BHE003748R0002 is an industrial-grade DC Governor Communication Board designed to manage data exchange between DC drive systems and external control environments. Specifically developed for use in ABB’s DCS400, DCS500, and DCS800 series drives, this communication board facilitates stable, high-speed transfer of digital signals and enhances the responsiveness of DC motor control applications.

Functioning as a communication bridge, the GD C742 AE supports command execution, speed feedback, diagnostics, and coordination of peripheral control modules. Its compact and robust design allows for deployment in demanding industrial settings such as steel processing plants, paper manufacturing lines, power generation units, and marine equipment automation.

ABB’s high-quality manufacturing standards ensure the board performs reliably under continuous operation, extreme environmental stress, and electrical noise. The component’s conformal coating and precise engineering also help it achieve long service life with minimal maintenance.

Product Specifications

| Parameter | Details |

|---|---|

| Product Name | GD C742 AE DC Governor Communication Board |

| Part Number | 3BHE003748R0002 |

| Manufacturer | ABB |

| Product Category | Drive Communication Interface |

| System Compatibility | ABB DCS400 / DCS500 / DCS800 |

| Functionality | Signal Transmission, Drive Communication |

| Signal Type | Digital (High-speed Industrial Interface) |

| Interface | ABB Proprietary Serial / Parallel Bus |

| Power Supply | 5 VDC |

| Cooling Type | Passive Cooling |

| PCB Coating | Conformal Coated for Industrial Protection |

| Mounting Style | Rack Mount (Module Slot Insertion) |

| Operating Temperature Range | 0°C to +60°C |

| Storage Temperature Range | -25°C to +85°C |

| Humidity Range | 5% – 95% (non-condensing) |

| Certifications | CE, UL, RoHS, ISO 9001 |

| Dimensions (W × H × D) | 235 × 125 × 20 mm |

| Weight | 0.2 kg |

Product Applications

-

Steel and Rolling Mills

Facilitates precise coordination of DC motor drives for rolling lines and cutting mechanisms. -

Paper and Pulp Production

Maintains synchronization between multiple DC-driven rollers, dryers, and slitters. -

Power Generation Facilities

Integrated in turbine control panels for exciter regulation and system balancing. -

Marine and Offshore Platforms

Supports propulsion and winch control where DC drives are preferred for torque stability. -

Mining and Material Handling

Enables reliable operation of hoists, conveyors, and crushers using DC drive systems. -

Industrial Cranes

Enhances response time and position control in crane automation systems.

Product Advantages

-

Reliable Communication Backbone

Ensures seamless and uninterrupted data transfer between drive controllers and supervisory systems. -

Optimized for ABB DC Drive Series

Full compatibility with DCS400, DCS500, and DCS800 systems provides integration flexibility. -

Built for Harsh Environments

Features conformal coating, EMI shielding, and temperature resilience for harsh industrial conditions. -

Compact and Lightweight

Small footprint and lightweight construction simplify rack installation and system expansion. -

Low Energy Consumption

Operates with only 5V DC supply, making it highly energy-efficient. -

Easy Maintenance and Diagnostics

Integrated status LEDs and test points allow for rapid troubleshooting. -

Passive Cooling Design

Avoids the need for fans or active thermal management, reducing potential points of failure. -

Industrial-Grade Longevity

Designed for 24/7 operation with MTBF (Mean Time Between Failures) far exceeding 100,000 hours. -

Minimal Signal Loss

Incorporates galvanic isolation to ensure signal integrity and fault protection. -

Global Certification

Complies with international standards for electrical safety and environmental performance.

Frequently Asked Questions (FAQ)

1. What is the function of the GD C742 AE communication board?

The board serves as a dedicated communication interface between ABB DC drive systems (such as the DCS800 series) and control networks. It facilitates high-speed, reliable data exchange, crucial for process control and monitoring.

2. Is the board compatible with all DCS800 models?

Yes, the GD C742 AE is designed to be compatible with most DCS800 drive variants. However, firmware version compatibility should be confirmed before installation to ensure seamless communication.

3. Does the board require special configuration after installation?

Typically, minimal configuration is required. In most cases, the board is plug-and-play within ABB systems. For advanced settings, ABB DriveWindow or similar commissioning tools can be used.

4. Can this board be replaced without powering down the system?

No, the board is not hot-swappable. Powering down the drive unit is mandatory before inserting or removing the GD C742 AE to prevent electrical damage and ensure safety.

5. How can I verify that the board is functioning correctly?

The board includes built-in status LEDs to indicate communication activity and fault states. Additionally, drive interface software can be used to monitor board status in real-time.

6. What kind of communication protocol does the board support?

The board uses ABB’s proprietary high-speed serial communication designed specifically for real-time industrial control. It is not intended for open protocols like Modbus or Profibus.

7. What is the typical lifespan of this board?

When operated in standard industrial environments with proper cabinet ventilation and grounding, the board has a mean time between failures (MTBF) of over 100,000 hours, translating to more than 10 years of stable use.

8. Are there any known environmental limitations for the board?

Yes, the recommended operating temperature is 0°C to +55°C. It should be installed in a dust-free, dry, and vibration-minimized control panel for optimal reliability.

9. Can the board be repaired if damaged?

ABB typically recommends replacing the board rather than repairing, as certified service centers may not support component-level repairs due to internal PCB design complexity and safety compliance.

10. Is this board suitable for synchronization between multiple drives?

The board supports communication with controllers that can manage multi-drive systems, but synchronization logic must be implemented at the system level (e.g., PLC or DCS). The board itself does not handle drive-to-drive synchronization independently.

Related Models from the Same or Compatible Series

| Model | Description | Drive Compatibility | Dimensions (mm) | Weight |

|---|---|---|---|---|

| GDC742AE Var.01 | Earlier revision of the communication board | DCS500 | 235 × 125 × 20 | 505 g |

| GDC740BE | Communication board with diagnostic features | DCS400 / DCS500 | 230 × 120 × 20 | 495 g |

| GDC743AE | Advanced I/O communication interface | DCS800 | 235 × 125 × 20 | 520 g |

| RDCO-01 | Option board for fieldbus communication | DCS800 | 100 × 150 × 30 | 300 g |

| GDC741AE | Signal interface and communication module | DCS500 | 235 × 125 × 20 | 510 g |

| RDCU-02C | Control unit with embedded communication | DCS800 | 210 × 180 × 50 | 1.2 kg |

Popular ABB Models from Similar Product Lines

| Model | Description | Application | Dimensions (mm) | Weight |

|---|---|---|---|---|

| PM864AK01 | High-performance controller for AC 800M | DCS process automation | 66 × 186 × 129 | 600 g |

| CI854AK01 | PROFIBUS interface module for 800xA | Fieldbus communication | 45 × 140 × 120 | 390 g |

| AI835 | Analog input module (HART-enabled) | Analog signal acquisition | 119 × 45 × 117 | 300 g |

| DO880 | 16-channel digital output module | Discrete actuator control | 119 × 45 × 117 | 310 g |

| TU810V1 | Terminal unit for I/O signal wiring | I/O signal distribution | 124 × 119 × 45 | 250 g |

| CI840A | Communication interface for ModuleBus systems | Distributed I/O communication | 119 × 45 × 117 | 280 g |

Excellent PLC

Excellent PLC