| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

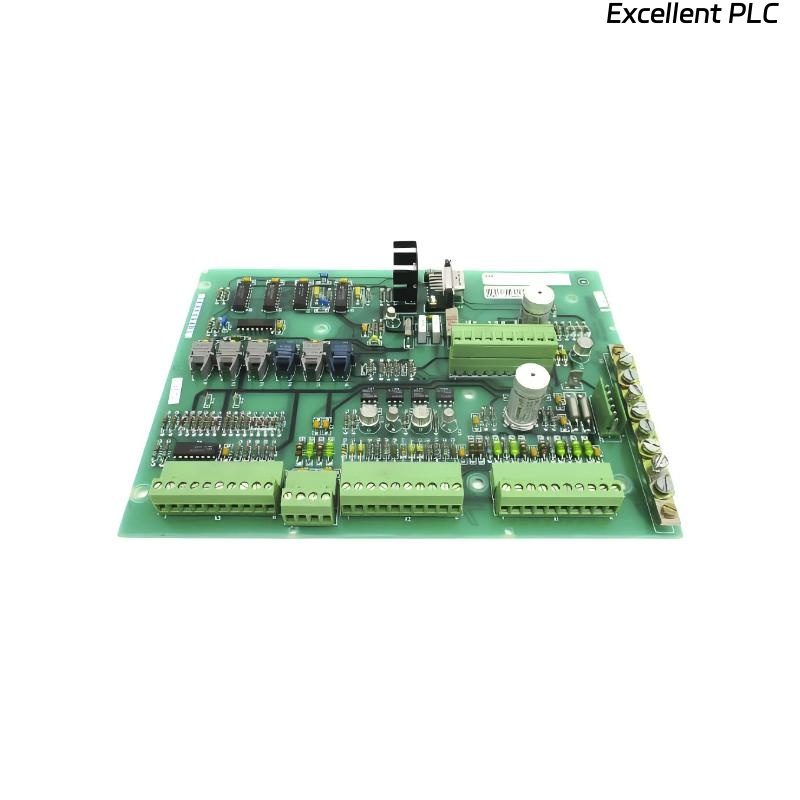

Product Overview

The ABB NBIO-21C (Part Number: 3BSE017427R1) is a compact, high-performance digital input/output (I/O) module designed for demanding industrial environments. This unit is a part of ABB’s renowned S800 I/O series, known for its modularity, flexibility, and robust field performance. The NBIO-21C is engineered for seamless integration into ABB control systems such as the AC 800M controller and other process automation platforms.

This basic I/O module handles both input and output digital signals, enabling communication between field devices (like sensors, switches, and actuators) and control systems. Its DIN rail mounting, rugged build, and wide operating temperature range make it a reliable choice for continuous industrial operations in fields such as power generation, chemical processing, water treatment, and more.

Technical Specifications

| Parameter | Details |

|---|---|

| Model Number | NBIO-21C |

| Part Number | 3BSE017427R1 |

| Series | S800 I/O |

| Input Channels | 8 Digital Inputs |

| Output Channels | 8 Digital Outputs |

| Input Voltage Range | 18–30 V DC |

| Input Current | Approx. 5 mA per channel |

| Output Type | Digital Output (Sourcing) |

| Output Voltage | 24 V DC (nominal) |

| Output Current Capacity | Max. 0.5 A per channel |

| Communication Interface | With I/O bus (proprietary ABB I/O communication) |

| Diagnostics | Channel diagnostics for fault detection |

| Operating Temperature | -25°C to +70°C |

| Storage Temperature | -40°C to +85°C |

| Humidity Tolerance | 5% to 95%, non-condensing |

| Mounting Type | DIN rail mounting |

| Protection Class | IP20 |

| Dimensions (H x W x D) | 100 x 140 x 70 mm |

| Weight | 0.5 kg |

| Compliance | CE, RoHS, UL, IEC 61131-2, ISO 9001 |

Applications

-

Power Generation Plants

Used for monitoring and controlling field equipment such as pumps, circuit breakers, and cooling systems. -

Oil and Gas Facilities

Provides reliable signal interfacing for emergency shutdown systems, compressors, and valves. -

Chemical and Petrochemical Plants

Manages complex batch processes and integrates with hazardous area equipment. -

Water and Wastewater Management

Controls pumps, filters, and gates in treatment plants, ensuring regulatory compliance and operational efficiency. -

Discrete Manufacturing

Enables real-time control and monitoring of assembly lines, robotic arms, and inspection stations.

Product Advantages

-

Compact and Modular

The NBIO-21C fits easily into existing systems and allows modular expansion without extensive rewiring. -

High Signal Integrity

Engineered with noise immunity and fault diagnostics, ensuring accurate data acquisition even in EMI-prone environments. -

Seamless Integration with ABB Systems

Fully compatible with AC 800M, Freelance, and other ABB DCS/PLC environments for unified automation. -

Field-Tested Reliability

Extensively tested for durability under extreme conditions and continuous operation cycles. -

Reduced Downtime

Integrated diagnostic functions enable faster troubleshooting, reducing maintenance intervals and downtime. -

Global Compliance

Meets international certifications and standards, suitable for use in global industrial markets.

Frequently Asked Questions (FAQ)

-

Is the NBIO-21C compatible with all ABB control systems?

The NBIO-21C is primarily designed for use with ABB’s AC 800M controller and S800 I/O system, but it may also integrate with other ABB platforms that support its I/O bus. -

Can the NBIO-21C be used in outdoor environments?

While the module itself is not weatherproof, it can be used outdoors when mounted within a protective enclosure that meets environmental protection standards. -

How are the I/O signals protected?

Each channel features short-circuit and overload protection, enhancing device longevity and field safety. -

Does the NBIO-21C support hot swapping?

Yes, the module supports hot swapping, allowing replacement without shutting down the entire system. -

What kind of diagnostics are available?

The module provides channel-level diagnostics, reporting faults such as open wire, short circuit, and overload. -

Is software configuration required?

Yes, the module must be configured using ABB’s Control Builder or other compatible ABB engineering tools. -

What is the power consumption of the unit?

The module typically consumes about 1.5 W, but this may vary depending on load conditions. -

Are there any limitations in signal response time?

The NBIO-21C is optimized for fast response times suitable for real-time control applications. -

Can it be used in SIL-rated systems?

For SIL applications, ABB offers specialized versions or modules certified for functional safety. -

What is the maintenance cycle of this module?

Maintenance is minimal, with periodic checks recommended every 12 months or per site conditions.

Related Models (Same Series)

| Model Number | Description |

|---|---|

| NBIO-22C | Basic I/O unit with expanded diagnostics |

| NBIO-23C | High-speed I/O variant for time-critical applications |

| AI820 | Analog input module for 4-20 mA signals |

| DO810 | Digital output module (16 channels) |

| DI810 | Digital input module (16 channels) |

| TU810 | Base unit for S800 I/O modules |

Popular ABB Models (Same Brand)

| Model Number | Description |

|---|---|

| AC 800M | High-performance process automation controller |

| ACS880 | Universal industrial drive for motor control |

| DCS880 | DC drive for flexible control in industrial settings |

| S800 I/O | Modular distributed I/O system |

| Freelance 2019 | Compact DCS solution for small-to-medium installations |

| 800xA | Integrated process automation system |

Excellent PLC

Excellent PLC