| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

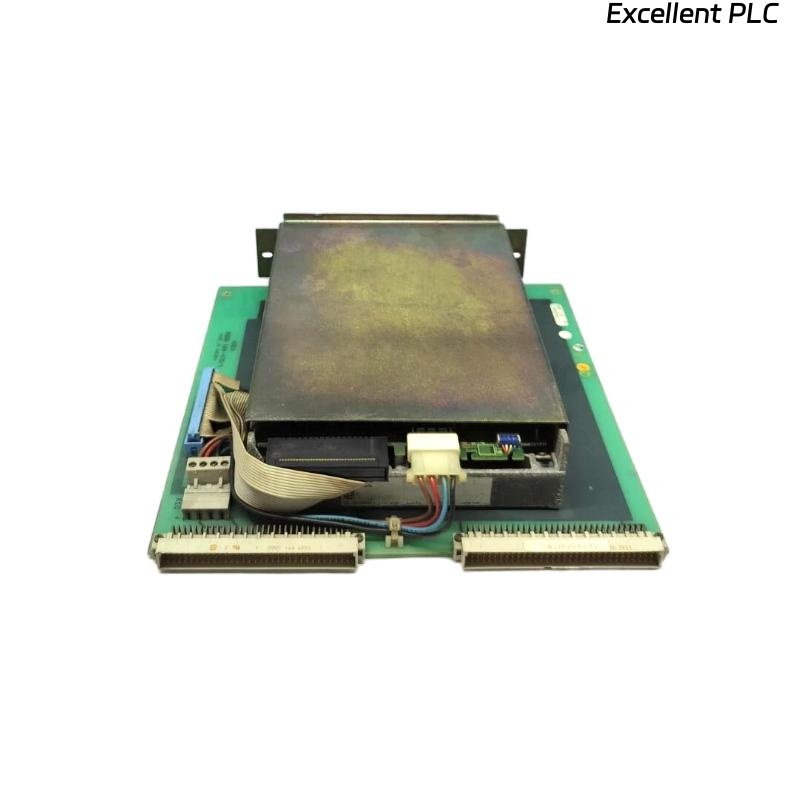

The ABB PCD230B101 3BHE022291R0101 Controller Module is a high-performance control unit used in ABB’s industrial automation and drive systems. Designed for precise and reliable process control, it serves as a central component in coordinating inputs, outputs, and communication within complex control architectures. With robust processing power and advanced communication protocols, the PCD230B101 supports a wide range of industrial applications where real-time performance and operational safety are critical.

This controller module is commonly integrated into ABB’s Symphony and drive control platforms, ensuring seamless interaction with other system components. It is built to handle harsh industrial environments while delivering consistent control, diagnostics, and communication capabilities.

Product Specifications

| Parameter | Description |

|---|---|

| Model Number | PCD230B101 |

| Part Number | 3BHE022291R0101 |

| Manufacturer | ABB |

| Series | Symphony / Industrial Drive Control |

| Function | Controller Module |

| Processor Type | High-speed industrial-grade processor |

| Memory Capacity | Integrated program and data memory (exact values vary per firmware) |

| Communication Interfaces | Ethernet, serial, and fieldbus compatible |

| I/O Compatibility | Supports multiple digital and analog I/O modules |

| Redundancy Support | Hot-swappable with redundancy options |

| Operating Voltage | 24V DC nominal |

| Power Consumption | <15W typical |

| Operating Temperature | 0°C to +60°C |

| Storage Temperature | -40°C to +85°C |

| Humidity Range | 5% to 95% non-condensing |

| Mounting Type | Rack or cabinet mounted |

| Compliance | CE, UL, RoHS |

| Dimensions (H×W×D) | 142 x 373 x 73.5 mm |

| Weight | 1.53 kg |

Product Applications

-

Industrial Automation: Acts as the central controller for process plants and manufacturing systems.

-

Drive and Motor Control: Coordinates high-performance motor drives in demanding industrial operations.

-

Power Generation: Used for turbine, generator, and auxiliary control in power plants.

-

Oil & Gas: Provides reliable control for drilling, refining, and pipeline systems.

-

Chemical Processing: Ensures safe and precise operation of chemical reactors and processing units.

-

Water and Wastewater Treatment: Maintains automated control of pumping and filtration systems.

Product Advantages

-

High Processing Power: Handles complex control algorithms and high-speed data exchange.

-

Advanced Communication: Supports Ethernet and fieldbus protocols for seamless integration.

-

Robust Design: Built for harsh industrial environments with strong electrical and thermal resilience.

-

Modular Integration: Easily connects to ABB I/O and expansion modules for flexible system design.

-

Redundancy Options: Supports hot-swappable redundant configurations to minimize downtime.

-

Accurate Diagnostics: Provides comprehensive system and module status monitoring for predictive maintenance.

FAQ

-

What control platforms are compatible with the PCD230B101 module?

The module is compatible with ABB Symphony series and industrial drive control systems, ensuring smooth integration with ABB architectures. -

What types of I/O modules can be connected to this controller?

It supports a wide range of ABB digital and analog I/O modules, enabling flexible configuration for various industrial applications. -

Does the PCD230B101 support redundant operation?

Yes, it supports hot-swappable redundancy configurations, allowing uninterrupted operation during maintenance or module replacement. -

Which communication interfaces are available on the controller?

The module provides Ethernet, serial, and fieldbus interfaces for reliable data communication across networks. -

How does the module handle real-time control tasks?

It uses a high-speed industrial processor and optimized firmware to execute real-time process control with minimal latency. -

What diagnostic functions are integrated into the module?

It offers system health monitoring, communication status checks, and self-diagnostic routines to ensure reliable operation. -

Can the PCD230B101 be integrated into safety-critical systems?

Yes, when configured with certified safety components, it can be used in SIL-rated applications depending on the overall system design. -

What power supply is required for the controller module?

The module operates with a 24V DC nominal power supply and consumes less than 15W under normal load. -

Is the module firmware upgradeable?

Yes, the firmware can be updated to support new features and maintain compatibility with evolving ABB systems. -

How does the module ensure signal integrity in noisy environments?

It employs galvanic isolation and noise suppression techniques, providing stable operation in electrically harsh industrial settings.

Related Models (Same Series)

| Model Number | Description |

|---|---|

| PCD231B101 | Advanced Controller Module |

| PCD232A101 | Process Control Module |

| PCD235B101 | Drive Interface Controller |

| PCD240A101 | Redundant Controller Unit |

| PCD245B101 | High-Speed Logic Controller |

| PCD250A101 | Communication Gateway Controller |

Popular ABB Models (Same Brand)

| Model Number | Description |

|---|---|

| 07KT98C GJR5253100R3260 | Controller Module |

| 07AC91 GJR5252300R0101 | I/O Module |

| DSAI130 57120001-AT | Analog Input Module |

| DSDI110A 57160001-AAA | Digital Input Module |

| DSRF180 57310255-AL | Relay Output Module |

| CI854AK01 3BSE030220R1 | Communication Interface Module |

Excellent PLC

Excellent PLC