| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

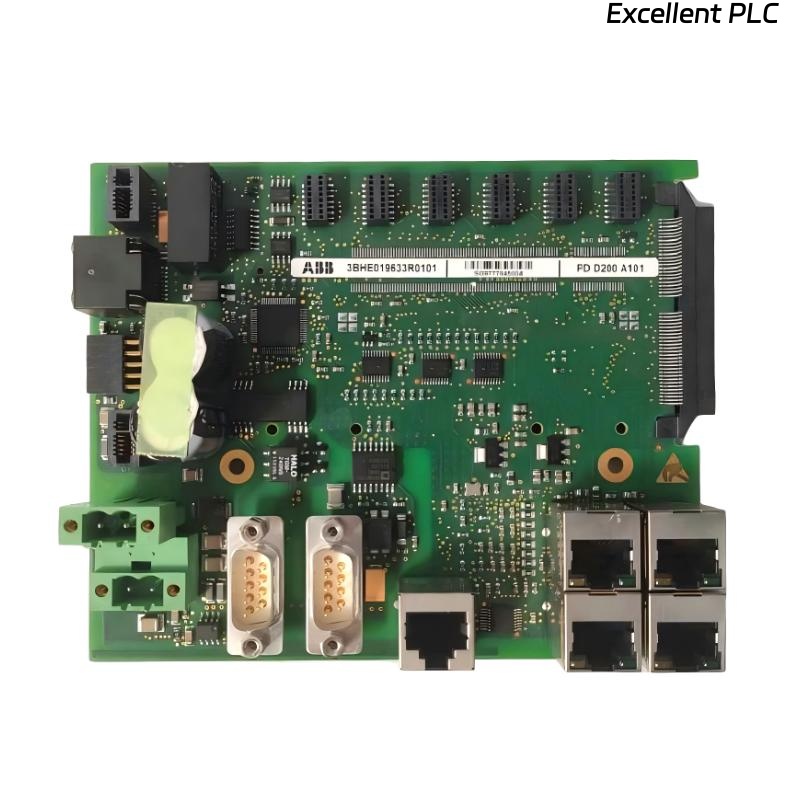

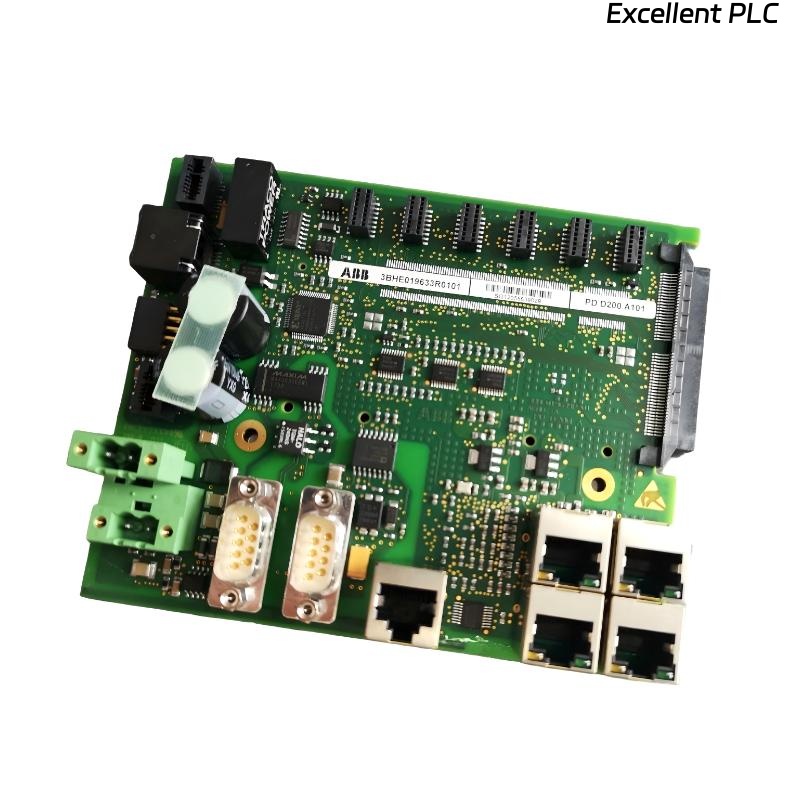

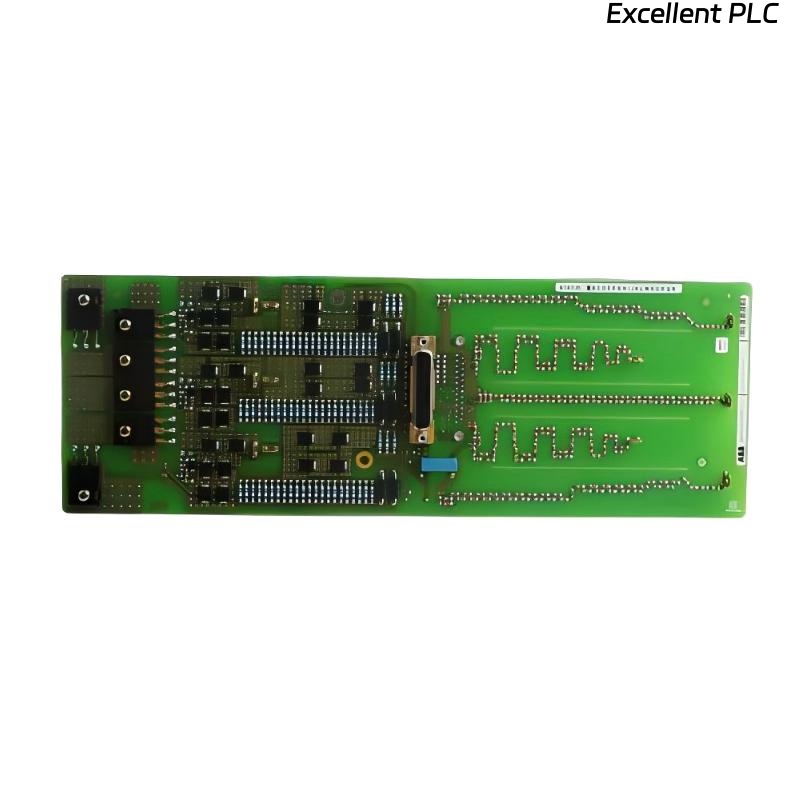

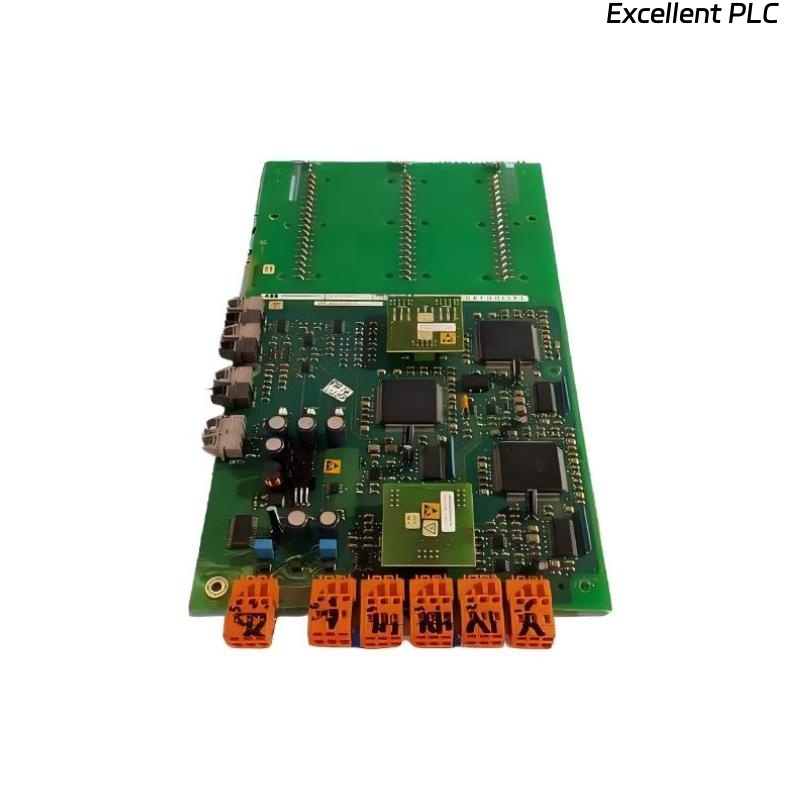

The ABB PD D200 A101 3BHE019633R0101 Control Board is a high-performance control module designed for use in ABB’s advanced automation and drive systems. It serves as a central processing and communication interface for real-time control, signal processing, and system coordination within ABB’s distributed control and power conversion platforms.

This board integrates microprocessor-based control logic, analog/digital signal conditioning, and robust communication protocols to ensure reliable system operation under industrial conditions. Its design reflects ABB’s commitment to precision engineering and long-term reliability.

Built on a multilayer FR4 epoxy PCB, the PD D200 A101 provides excellent electrical isolation, minimal signal interference, and superior mechanical stability. It is conformal coated to protect against dust, humidity, and chemical exposure, making it suitable for deployment in harsh industrial environments such as power generation, oil & gas, and heavy manufacturing facilities.

The PD D200 A101 functions as a key component in controlling and coordinating process equipment, ensuring synchronization between different control subsystems, and maintaining system integrity even under dynamic load and environmental conditions.

Technical Specifications

| Parameter | Description |

|---|---|

| Manufacturer | ABB |

| Model Number | PD D200 A101 3BHE019633R0101 |

| Product Type | Control Board |

| System Compatibility | ABB drive systems, excitation control systems, and process automation |

| Functional Role | Control logic processing, signal conditioning, communication coordination |

| Processor Type | 32-bit microcontroller with integrated signal processing unit |

| Clock Frequency | 40 MHz |

| Memory Capacity | 512 KB flash, 64 KB RAM |

| Input Voltage | +5 VDC and ±15 VDC (via system backplane) |

| Power Consumption | Approx. 10 W |

| Communication Interface | High-speed serial link / ABB proprietary control bus |

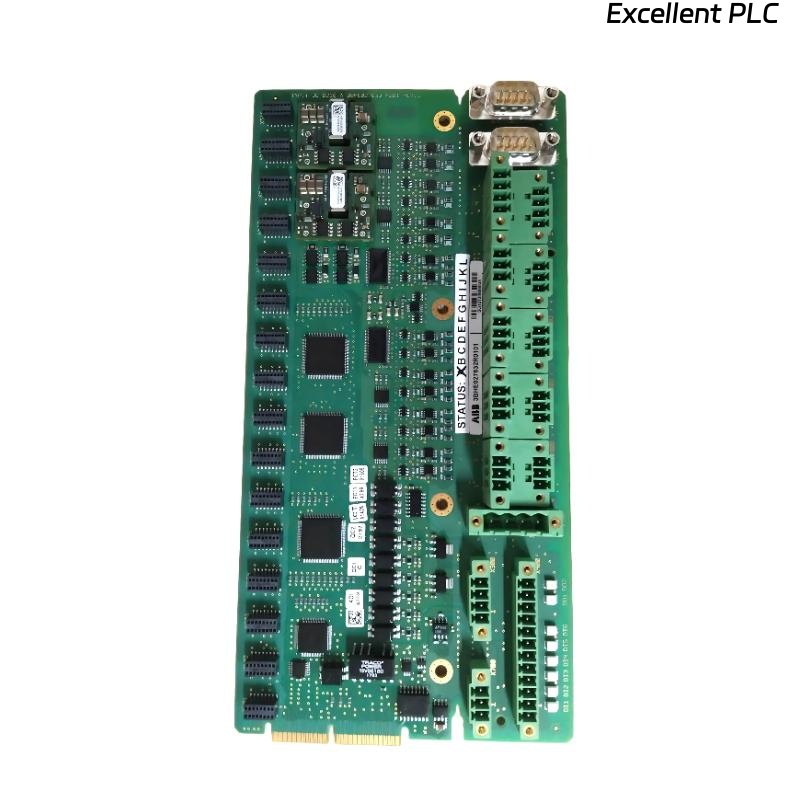

| Analog Inputs | Up to 16 configurable channels |

| Analog Outputs | 8 channels with 12-bit resolution |

| Digital I/O | 24 logic-level channels (isolated) |

| Isolation Voltage | 1500 VDC between field and logic circuits |

| Protection Features | Overvoltage, ESD, reverse polarity, and surge suppression |

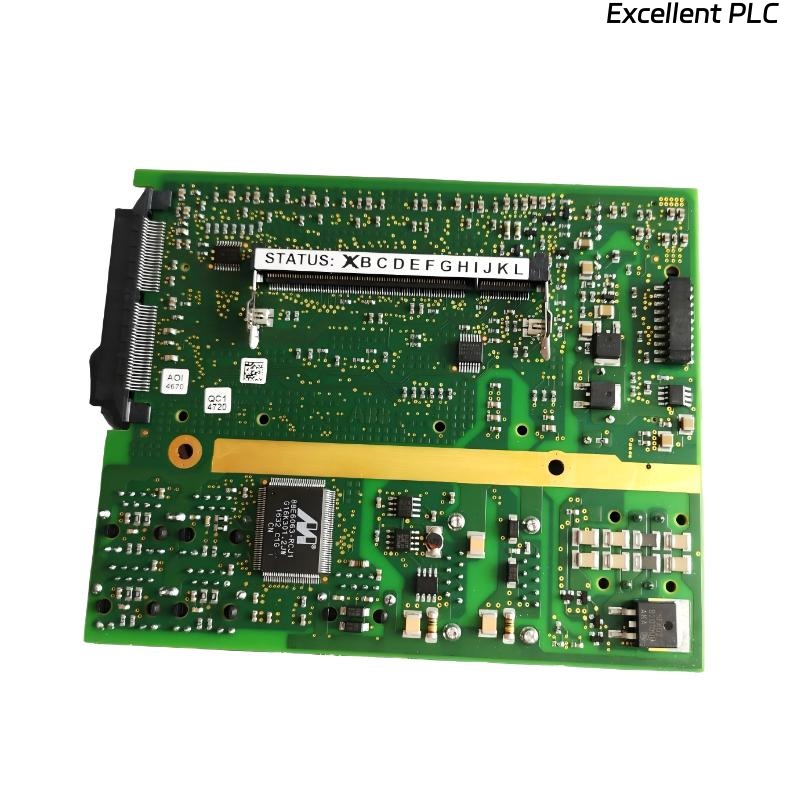

| Diagnostics | Onboard LEDs for status and fault indication |

| Operating Temperature | -25°C to +70°C |

| Storage Temperature | -40°C to +85°C |

| Humidity Range | 5%–95% non-condensing |

| Vibration Resistance | 2 g (10–500 Hz) |

| Shock Resistance | 15 g (11 ms half-sine) |

| PCB Material | Multilayer FR4 epoxy resin, conformal coated |

| Compliance | CE, UL, RoHS, ISO 9001 certified |

| Mounting Type | Rack-mounted plug-in board |

| Dimensions | 150 × 130 × 25 mm |

| Weight | 0.5 kg |

Product Applications

The ABB PD D200 A101 3BHE019633R0101 Control Board is a vital part of ABB’s automation control infrastructure, offering superior performance and dependable functionality across a wide range of industrial systems.

Typical application fields include:

-

Power Generation Systems: Used for turbine, generator, and excitation control where precise signal coordination is required.

-

Drive Control Systems: Manages real-time motor speed regulation, torque control, and drive synchronization.

-

Process Automation: Interfaces with ABB DCS systems for closed-loop process control and equipment communication.

-

Oil and Gas Applications: Provides stable control under harsh conditions with excellent resistance to vibration and contaminants.

-

Industrial Manufacturing: Supports complex process sequencing and real-time data communication in production environments.

-

Marine and Offshore Systems: Used in propulsion and auxiliary power systems for reliable operational control under marine conditions.

This board ensures stable signal transmission, real-time control synchronization, and robust system integrity, making it an essential component for high-reliability automation environments.

Product Advantages

-

High Computational Performance: Equipped with a 32-bit microcontroller for fast control processing.

-

Reliable Communication: Uses ABB’s proprietary high-speed bus system to maintain synchronization between modules.

-

Superior Electrical Protection: Integrated circuits protect against surges, ESD, and overvoltage events.

-

Enhanced Signal Integrity: Multilayer PCB minimizes crosstalk and provides excellent EMI/EMC immunity.

-

Industrial-Grade Durability: Conformal coating ensures long-term operation in dusty or humid environments.

-

Easy Maintenance: Onboard diagnostic LEDs simplify system monitoring and troubleshooting.

-

Flexible Configuration: Supports a wide range of analog and digital I/O functions.

-

Temperature Stability: Performs reliably across a wide temperature range.

-

Interchangeability: Fully compatible with other ABB PD D-series control modules.

-

Proven ABB Quality: Designed and manufactured under ABB’s rigorous quality control standards.

FAQ

-

What is the main function of the ABB PD D200 A101 board?

It provides control logic processing, signal conditioning, and communication management in ABB’s drive and control systems. -

Which ABB systems can the PD D200 A101 be used with?

It is compatible with ABB drive control systems, excitation systems, and process automation platforms. -

What type of processor is integrated in this control board?

The board uses a 32-bit microcontroller optimized for real-time industrial control tasks. -

Does the board support analog and digital signals simultaneously?

Yes, it includes both analog and digital I/O channels for mixed-signal applications. -

How does the board communicate with other ABB modules?

It uses a high-speed serial communication bus designed for ABB control systems. -

What kind of protective measures are built into the board?

It features overvoltage, surge, ESD, and reverse polarity protection circuits. -

Is the board conformal coated for environmental protection?

Yes, it is coated to resist humidity, corrosion, and dust intrusion. -

How is system diagnostics performed?

The board includes onboard status LEDs that indicate power, fault, and operational conditions. -

Can this board be configured for custom control logic?

Yes, it supports configurable parameters and can be programmed for specific control applications. -

Is the PD D200 A101 backward compatible with earlier ABB PD D-series modules?

Yes, it is backward compatible with earlier versions, maintaining electrical and mechanical interchangeability.

Related or Equivalent Models (Same Series)

| Model Number | Description | Key Feature |

|---|---|---|

| PD D200 A102 3BHE019633R0102 | Control Board | Updated firmware with extended diagnostics |

| PD D201 A01 3BHE020000R0101 | Signal Processing Board | Enhanced analog filtering capability |

| PD D202 A01 3BHE020100R0101 | Logic Control Board | Improved digital I/O handling |

| PD D203 A01 3BHE020200R0101 | Communication Interface Board | Supports dual-channel communication |

| PD D204 A01 3BHE020300R0101 | Process Control Module | Optimized for turbine and generator control |

| PD D205 A01 3BHE020400R0101 | Feedback Interface Board | High precision analog feedback conversion |

Popular ABB Models (Same Brand)

| Model Number | Product Type | Main Function |

|---|---|---|

| PM864AK01 3BSE018161R1 | CPU Controller Module | Central processor for ABB AC800M systems |

| AO810V2 3BSE038415R1 | Analog Output Module | Provides current and voltage analog outputs |

| DO810 3BSE008510R1 | Digital Output Module | Controls external actuators and relays |

| DI810 3BSE008508R1 | Digital Input Module | Receives digital signals from field devices |

| CI854AK01 3BSE030220R1 | Communication Interface | PROFIBUS DP communication adapter |

| SDCS-PIN-51 3BSE004939R1 | Control Interface Board | Interfaces with ABB drive control modules |

Excellent PLC

Excellent PLC