| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

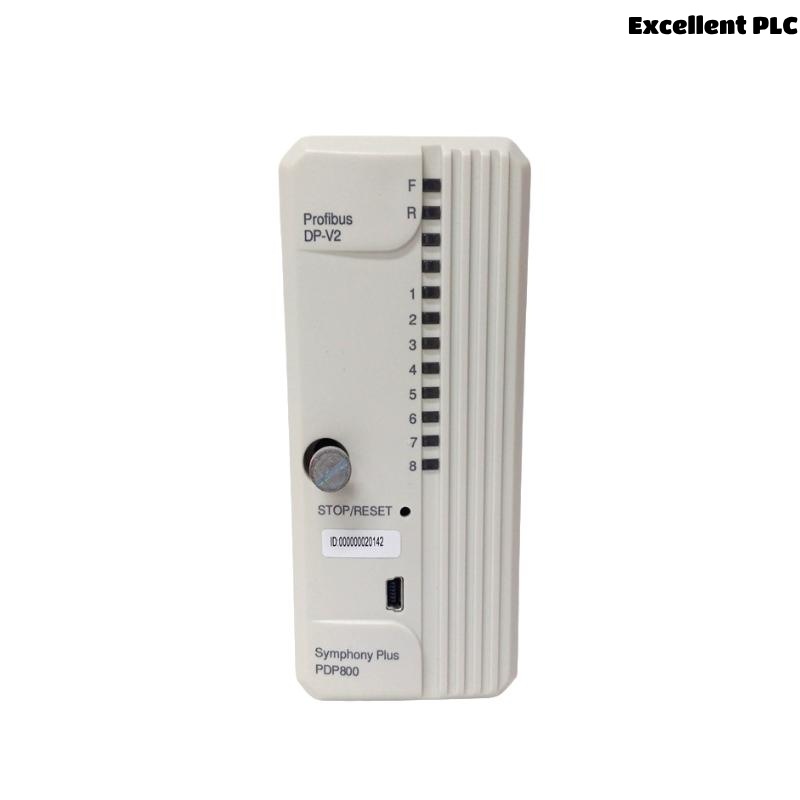

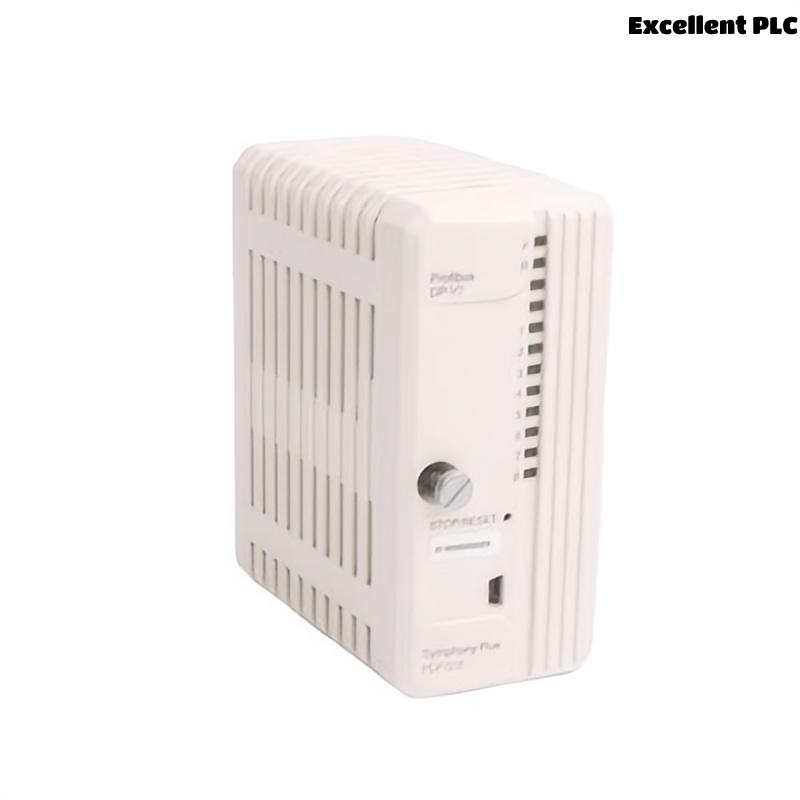

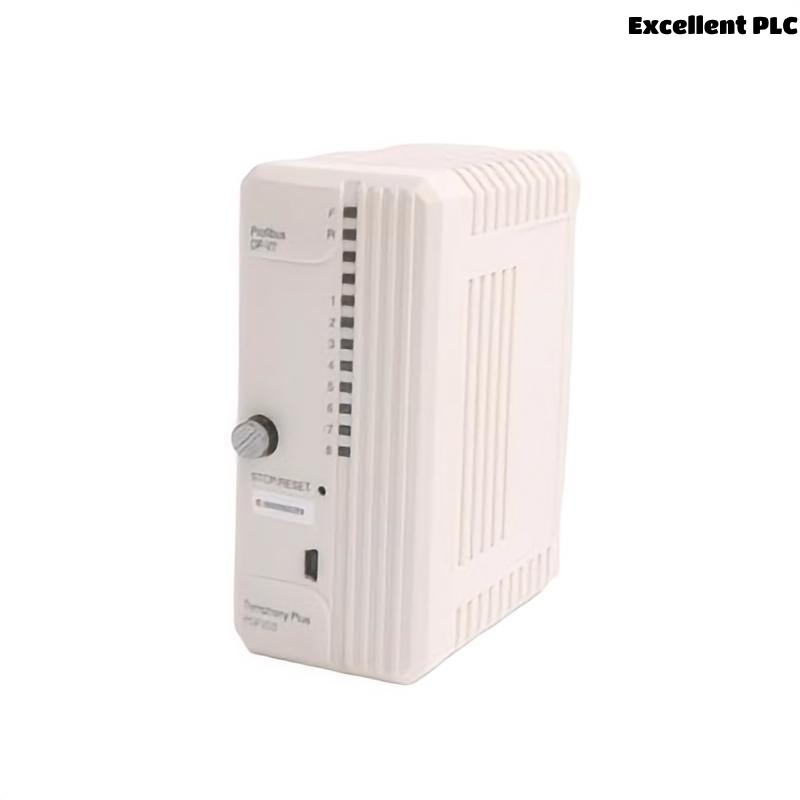

The ABB PDP800 Profibus DP V0/V1/V2 Master Module is a high-performance communication interface designed for ABB drive systems and industrial automation platforms. Acting as a Profibus DP master, it enables seamless communication between ABB drives, controllers, and field devices over the Profibus network. Supporting DP-V0, DP-V1, and DP-V2 protocols, the PDP800 provides reliable and deterministic data exchange essential for real-time industrial applications.

Engineered to meet the demanding requirements of process automation, this module ensures robust communication, high-speed performance, and easy integration into ABB drive systems. It is widely used in industries such as power generation, oil & gas, water treatment, and manufacturing for optimized process control and monitoring.

Product Specifications

| Parameter | Description |

|---|---|

| Model Number | PDP800 |

| Manufacturer | ABB |

| Function | Profibus DP Master Module |

| Supported Protocols | Profibus DP-V0, DP-V1, DP-V2 |

| Data Transfer Rate | Up to 12 Mbps |

| Device Support | Up to 125 Profibus devices |

| Communication Interface | RS-485 differential bus |

| Redundancy Support | Supports redundant network topologies |

| Diagnostics | Integrated network and device diagnostics |

| Power Supply Voltage | 24V DC nominal |

| Power Consumption | <10W typical |

| Operating Temperature | 0°C to +60°C |

| Storage Temperature | -40°C to +85°C |

| Humidity Range | 5% to 95% non-condensing |

| Mounting Type | DIN-rail or cabinet mounted |

| Compliance | CE, UL, RoHS |

| Dimensions (H×W×D) | 243.84 × 73.66 × 170.18 mm |

| Weight | 0.8 kg |

Product Applications

-

Drive Control Systems: Enables communication between ABB drives and central controllers via Profibus.

-

Process Automation: Integrates sensors, actuators, and PLCs into a unified communication network.

-

Power Generation: Provides reliable data exchange for turbine, generator, and auxiliary control systems.

-

Oil & Gas: Supports pipeline control, refining processes, and remote field device integration.

-

Manufacturing Automation: Links production machinery and control systems for optimized performance.

-

Water and Wastewater Treatment: Ensures coordinated operation of pumps, valves, and monitoring devices.

Product Advantages

-

Multi-Protocol Support: Handles DP-V0, DP-V1, and DP-V2 communication standards for flexible integration.

-

High-Speed Data Exchange: Operates at up to 12 Mbps for real-time control applications.

-

Large Device Capacity: Supports up to 125 Profibus field devices per network.

-

Integrated Diagnostics: Provides advanced network and device status monitoring for preventive maintenance.

-

Redundancy Ready: Supports redundant network configurations for high availability systems.

-

Easy ABB Integration: Optimized for ABB drives and control platforms with straightforward configuration tools.

FAQ

-

Which Profibus DP versions does the PDP800 support?

The module supports DP-V0, DP-V1, and DP-V2 protocols, making it compatible with a wide range of devices. -

How many field devices can be connected to one PDP800 module?

It supports up to 125 Profibus devices on a single network segment. -

What is the maximum communication speed of the module?

The PDP800 can operate at data rates up to 12 Mbps for high-speed industrial networks. -

Does the module support redundant Profibus networks?

Yes, it is designed to integrate into redundant network topologies for increased system reliability. -

What type of physical interface does the PDP800 use?

It uses an RS-485 differential bus standard for Profibus communication. -

How are diagnostics reported from the PDP800 to the control system?

The module provides real-time network and device diagnostics via the Profibus protocol and ABB drive interface. -

Is the PDP800 compatible with ABB drive systems and controllers?

Yes, it is optimized for ABB drives and integrates seamlessly with ABB automation platforms. -

Can the PDP800 handle cyclic and acyclic data communication?

Yes, it supports both cyclic process data exchange and acyclic parameter communication as defined in DP-V1 and DP-V2. -

What power supply does the module require?

It operates with a nominal 24V DC supply and consumes less than 10W under typical conditions. -

How does the PDP800 ensure reliable operation in industrial environments?

It features galvanic isolation, error-checking mechanisms, and noise suppression to maintain stable communication in electrically noisy conditions.

Related Models (Same Series)

| Model Number | Description |

|---|---|

| PDP810 | Profibus DP Slave Module |

| PDP820 | Profibus DP Redundant Master |

| PDP700 | Profibus DP Interface for ABB Drives |

| PDP720 | High-Speed Profibus Adapter |

| PDP850 | Profibus Gateway Module |

| PDP860 | Profibus Network Diagnostic Module |

Popular ABB Models (Same Brand)

| Model Number | Description |

|---|---|

| 07KT98C GJR5253100R3260 | Controller Module |

| 07AC91 GJR5252300R0101 | I/O Module |

| DSAI130 57120001-AT | Analog Input Module |

| DSDI110A 57160001-AAA | Digital Input Module |

| DSRF180 57310255-AL | Relay Output Module |

| CI854AK01 3BSE030220R1 | Communication Interface Module |

Excellent PLC

Excellent PLC