| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

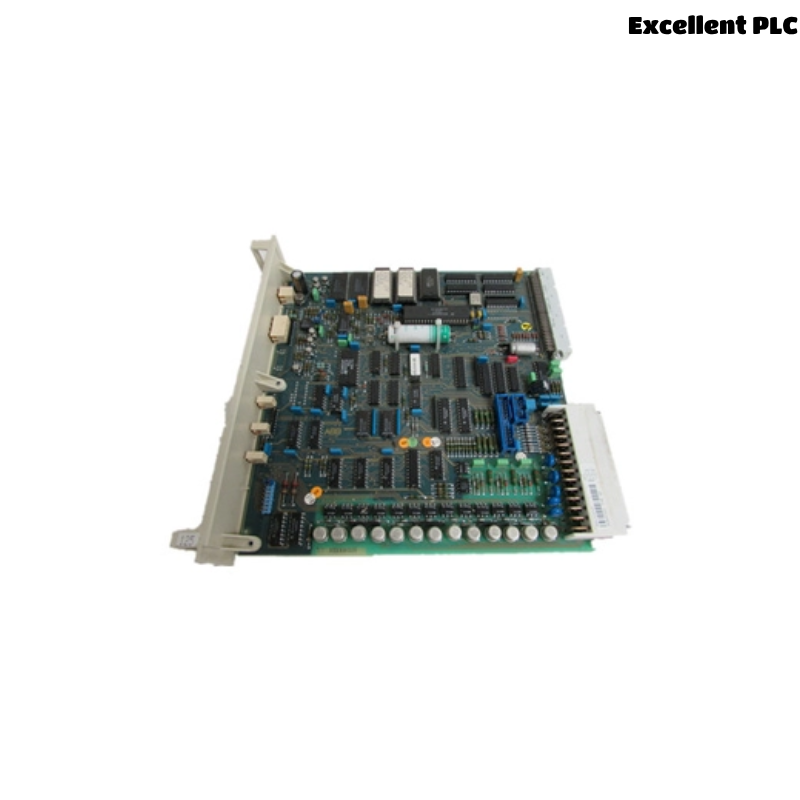

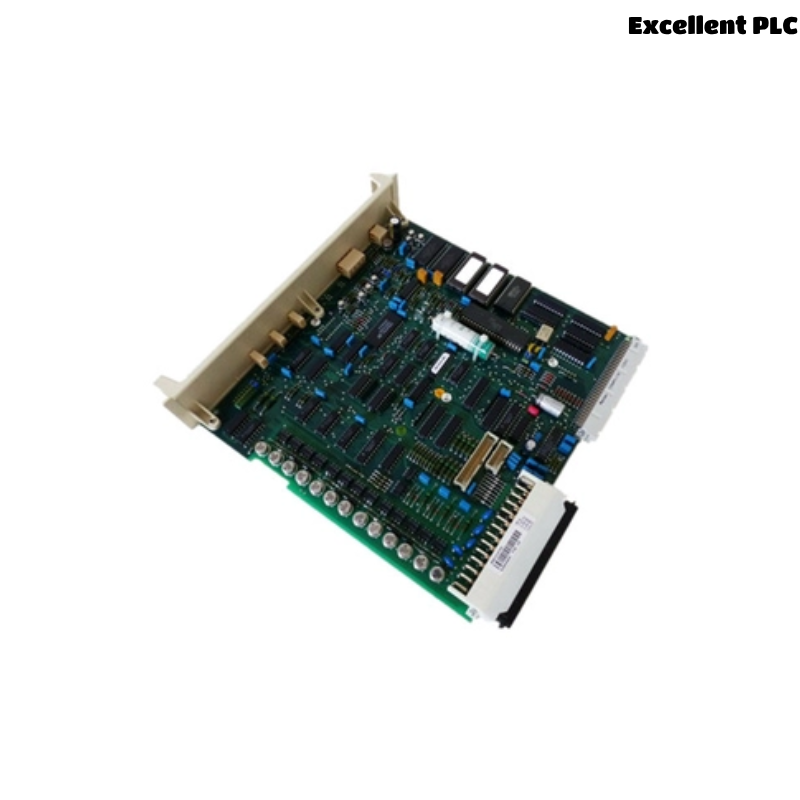

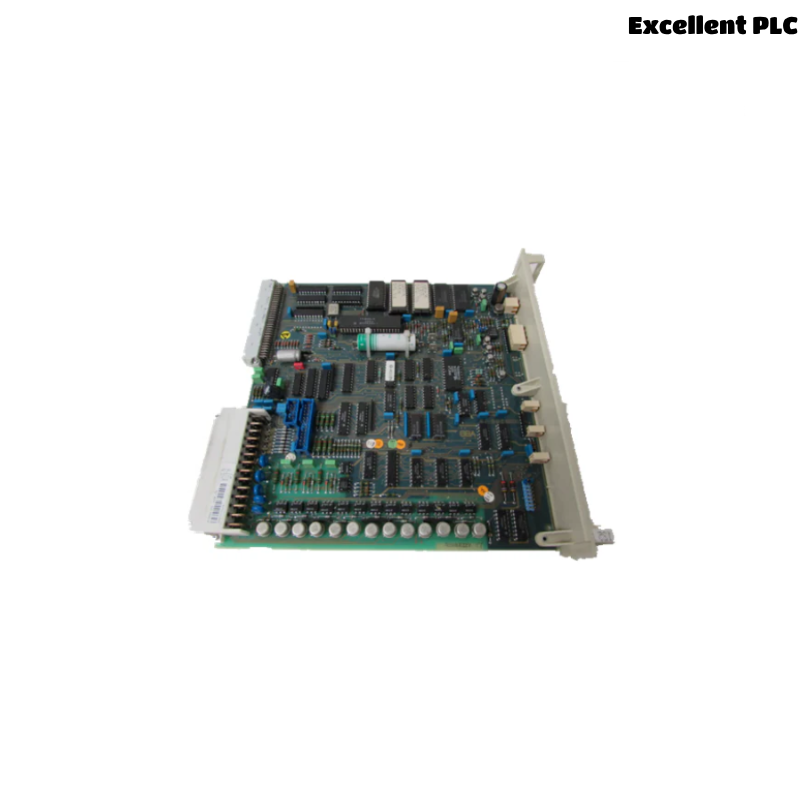

The ABB PFBK165 3BSE000470R1 is a high-performance fieldbus communication module designed for industrial automation systems. It serves as a critical component in ABB’s AC 800M controller family, enabling seamless integration of field devices into control networks. This module supports PROFIBUS DP/V1 protocols, ensuring reliable data exchange between controllers and field instruments. Its rugged design and advanced diagnostics make it suitable for demanding industrial environments, including power generation, oil & gas, and process automation.

Product Parameters

| Parameter | Specification |

|---|---|

| Model Number | PFBK165 3BSE000470R1 |

| Communication Protocol | PROFIBUS DP/V1 |

| Data Transfer Rate | 9.6 kbps to 12 Mbps |

| Operating Voltage | 24 V DC (typical) |

| Power Consumption | ≤ 2.5 W |

| Dimensions | 160 × 50 × 110 mm |

| Weight | 0.65 kg |

| Operating Temperature | -40°C to +70°C |

| Relative Humidity | 5% to 95% (non-condensing) |

| Certifications | CE, UL, ATEX (for hazardous areas) |

| Connector Type | 9-pin D-sub (PROFIBUS) |

Product Applications

The PFBK165 module is widely used in:

-

Process Automation: Integrates sensors and actuators in chemical/petrochemical plants.

-

Power Generation: Facilitates communication in turbine control and grid management systems.

-

Oil & Gas: Ensures reliable data transmission in offshore platforms and refineries.

-

Manufacturing: Connects PLCs to robotic arms and conveyor systems.

-

Water Treatment: Monitors pumps and valves in SCADA networks.

Product Advantages

-

High Reliability: Robust construction for harsh environments (dust, vibration, EMI).

-

Fast Diagnostics: Built-in LEDs for real-time status monitoring.

-

Easy Integration: Plug-and-play compatibility with AC 800M controllers.

-

Wide Temperature Range: Operates in extreme cold/heat (-40°C to +70°C).

-

Certified Safety: ATEX compliance for explosive atmospheres.

Frequently Asked Questions (FAQ)

-

Q: What is the maximum cable length supported by PFBK165?

A: Up to 1,200 meters at 9.6 kbps (shielded twisted pair). -

Q: Can this module be used in redundant systems?

A: Yes, it supports redundancy when paired with a backup PROFIBUS master. -

Q: Is the PFBK165 hot-swappable?

A: No, power must be turned off before installation/removal. -

Q: How many devices can be connected per segment?

A: Up to 32 nodes (including the master). -

Q: What software is needed for configuration?

A: ABB’s Control Builder M or equivalent PROFIBUS configurators. -

Q: Does it support PROFIBUS PA?

A: No, only PROFIBUS DP/V1. A separate PA linker is required. -

Q: What is the MTBF (Mean Time Between Failures)?

A: Approximately 150,000 hours under standard conditions. -

Q: Can the module be replaced while the system is running?

A: Can the module be replaced while the system is running? -

Q: Can it operate in Class I Div 2 areas?

A: Yes, with ATEX/IECEx certification. -

Q: What is the warranty period?

A: Standard 12 months from date of purchase.

Recommended Related & Popular Models

Same Series (AC 800M Family)

| Model | Description |

|---|---|

| PFBK162 3BSE000469R1 | PROFIBUS DP module (redundant option) |

| PFBK163 3BSE000471R1 | Enhanced diagnostics version |

| CI854 3BSE018144R1 | Ethernet/IP communication module |

| CI858 3BSE018135R1 | Modbus TCP interface |

| TB811 3BSE008548R1 | Termination board for PFBK165 |

| PM802F 3BSE010199R1 | Compact controller with PROFIBUS support |

Popular ABB Models (Other Series)

| Model | Description |

|---|---|

| ACS880-01-04A0-3 | Industrial drive (4 kW) |

| REF615C-E | Feeder protection relay |

| DSQC688 | Robot controller (IRB 6600) |

| CP635-T | HMI panel (6.5″ touchscreen) |

| S800 I/O Module | Remote I/O for hazardous areas |

| UMC100BF | Motor controller (fluid handling) |

Excellent PLC

Excellent PLC