| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

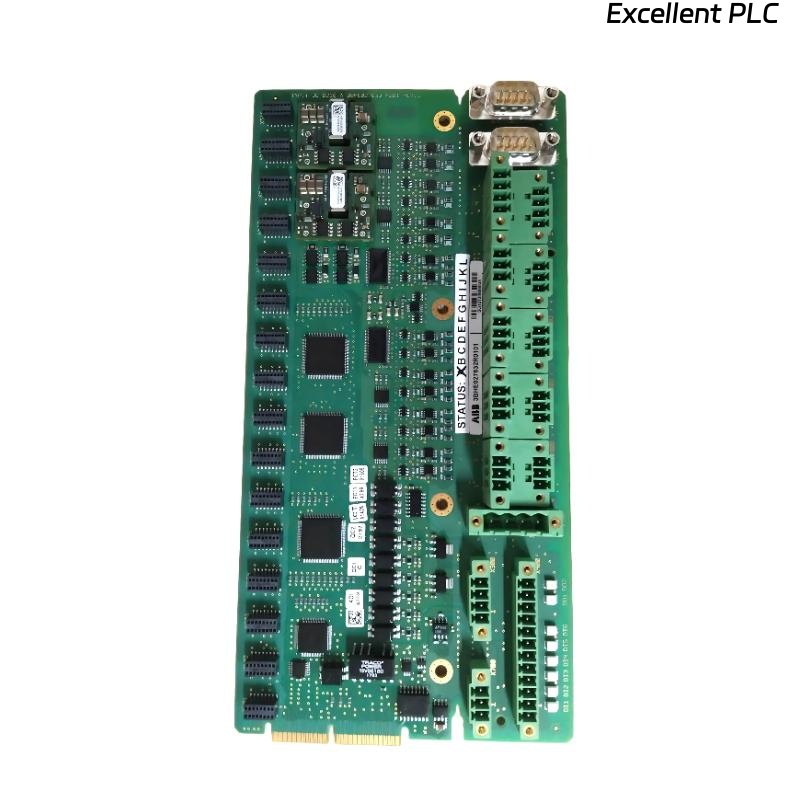

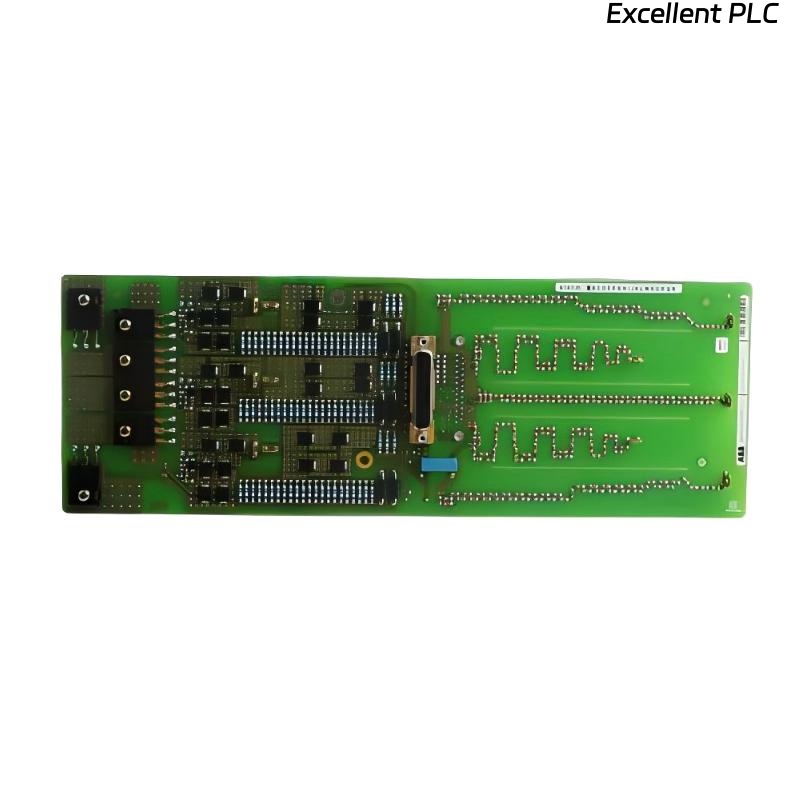

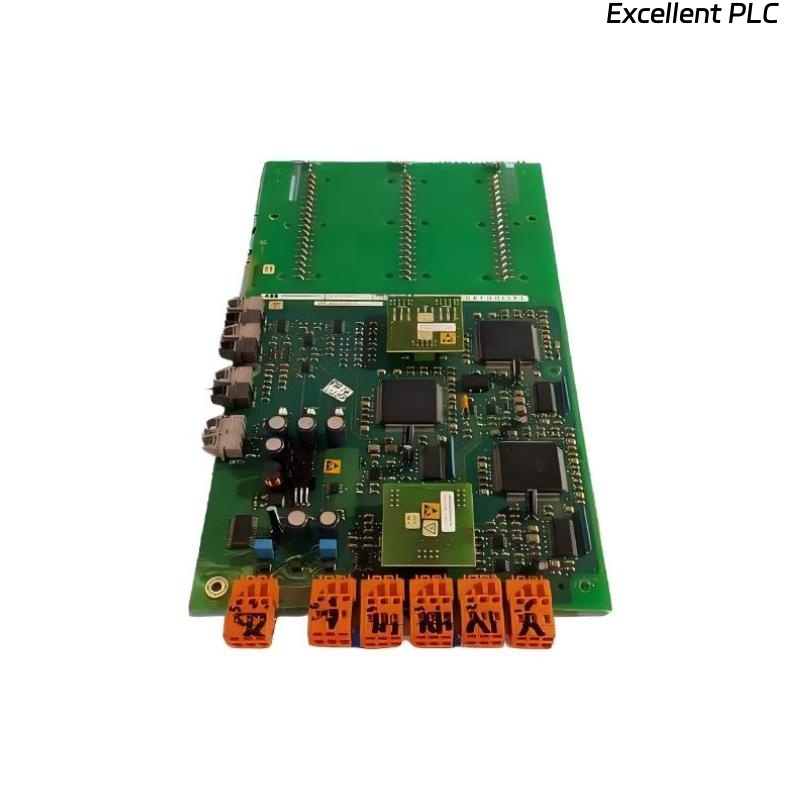

The ABB PFEA112-65 is an advanced tension electronics module designed specifically for use within tension measurement systems in industrial drive control applications. As a component of ABB’s well-established Drive Systems, it plays a critical role in processing signals from force sensors and delivering accurate tension control feedback to automation systems, especially in web handling industries such as paper, plastic film, foil, textile, and converting processes.

The module is part of the PFEA1xx series, developed to offer precise and reliable measurement performance, excellent linearity, and integration with ABB’s DriveIT and AC 800M control systems. This model, PFEA112-65, offers enhanced signal filtering, low drift characteristics, and dependable operation in harsh industrial conditions.

Product Specifications

| Parameter | Details |

|---|---|

| Model Name | PFEA112-65 |

| Part Number | 3BSE030369R65 |

| Function | Tension Electronics / Signal Conditioning Module |

| Power Supply | 24 V DC |

| Input Channels | 2 differential strain gauge inputs |

| Signal Input Type | mV/V (millivolts per volt) |

| Sensor Supply Voltage | 5 V DC |

| Analog Output | ±10 V / 0–10 V (configurable) |

| Digital Interface | RS-232 / RS-485 for diagnostics and configuration |

| Temperature Range | -10°C to +55°C |

| Mounting | DIN Rail Mountable |

| Protection Class | IP20 |

| Dimensions (W x H x D) | 100 x 180 x 120 mm |

| Weight | 1 kg |

| Compliance | CE, RoHS, UL Listed |

Applications

The PFEA112-65 tension electronics module is used across a broad range of industrial automation environments that require precision tension control. Typical applications include:

-

Paper Machines: For accurate web tension control in paper production.

-

Plastic and Film Processing: Ensures consistent tension during extrusion or winding.

-

Textile Machines: Maintains uniform thread tension during weaving or spinning.

-

Printing Presses: Prevents print distortion caused by variable tension.

-

Steel and Metal Strip Processing: Helps maintain proper elongation and feed rate.

-

Packaging Machinery: Controls web feed during automated packaging cycles.

Product Advantages

-

High Signal Accuracy: The module delivers precise signal conditioning for strain gauge sensors, crucial for web tension control.

-

Dual Channel Input: Supports two input channels for redundancy or simultaneous multi-point measurements.

-

Compact and Rugged: Slim DIN rail design with robust housing suitable for industrial panels.

-

Low Drift and High Stability: Maintains measurement accuracy over time and temperature fluctuations.

-

Simple Integration: Designed for direct compatibility with ABB’s automation platforms (AC 800M, DriveIT).

-

Flexible Output Options: Configurable analog output (±10V, 0–10V) for easier PLC/drive interface.

-

Diagnostic Interface: RS-232/RS-485 for parameterization, diagnostics, and remote support.

-

Reduced Downtime: LED indicators and software tools allow quick fault detection and system verification.

-

Long Lifecycle: Industrial-grade electronics ensure long-term reliability with minimal maintenance.

-

Standard Compliance: Meets CE, RoHS, and UL requirements for global installation.

Frequently Asked Questions (FAQ)

-

Q: What is the recommended cable type for connecting strain gauge sensors to the PFEA112-65?

A: Shielded twisted pair cables with low capacitance are recommended to minimize signal noise and ensure measurement accuracy, especially over longer distances. -

Q: Can the PFEA112-65 handle unbalanced or noisy strain gauge signals from old sensors?

A: Yes, the module includes differential input and internal filtering mechanisms designed to reject common-mode noise, improving performance even in suboptimal sensor conditions. -

Q: Is it possible to switch between the two input channels without power cycling the module?

A: Yes, switching between channels is supported via configuration software through the RS-232 or RS-485 interface. No need to restart the module. -

Q: What are the LED indicators on the front panel used for?

A: The front-facing LEDs provide quick diagnostics for power status, sensor fault, signal error, and operational readiness, which helps during commissioning and maintenance. -

Q: How can I verify if the sensor supply voltage (5V DC) is functioning correctly?

A: Using a multimeter, measure across the sensor supply terminals. A deviation from 5V indicates either an internal fault or external overload. -

Q: What is the maximum load impedance for the analog output signal?

A: The analog output can drive loads with an impedance of at least 10 kΩ. Lower impedance loads may cause signal distortion or voltage drop. -

Q: Can two PFEA112-65 modules be used together in a master-slave tension monitoring configuration?

A: While each module operates independently, you can synchronize output data via the PLC or controller receiving analog inputs, provided your system supports it. -

Q: How is zero-load calibration performed on this module?

A: Calibration is typically done via the configuration software or DIP switches. Zero calibration involves applying no load to the sensor and setting the baseline reading to zero volts or equivalent. -

Q: What happens if a sensor becomes disconnected during operation?

A: The module will detect the sensor fault, activate the corresponding LED warning, and optionally drive the output to a failsafe state depending on configuration. -

Q: Does the PFEA112-65 support sensor redundancy in case one input fails?

A: It supports dual input channels, which can be configured for redundancy or independent monitoring. In redundancy mode, the second channel can act as a backup for continuity of tension control.

Related or Same-Series Models

| Model | Function | Input Type | Output | Notes |

|---|---|---|---|---|

| PFEA111-20 | Tension module for load cell signal input | Strain gauge (1 ch) | ±10 V / 4–20 mA | Basic single-channel model |

| PFEA112-20 | Dual channel version | 2x strain gauge | Analog | Predecessor of PFEA112-65 |

| PFEA111-65 | Signal conditioning unit | Strain gauge (1 ch) | 0–10 V | Same generation, single-channel variant |

| PFEA114-20 | Enhanced module with digital filter | Strain gauge | Configurable | High-performance filtering |

| PFEA115-20 | Tension amplifier with configurable scaling | mV/V | Analog + Relay | Includes alarm output |

| PFEA116-20 | Load cell input interface with fast sampling | mV/V strain gauge | Analog | High-speed sampling for dynamic systems |

Popular ABB Automation Products

| Model | Category | Application | Notes |

|---|---|---|---|

| AC800M | Control System CPU | Process and discrete automation | Modular, high-performance PLC |

| DCS800 | DC Drive | High power DC motor control | Integrated tension control functions |

| ACS880 | AC Drive | Versatile motor control | Compatible with tension feedback systems |

| PM861K01 | Control Builder CPU | 800xA control applications | Frequently paired with PFEA modules |

| S800 I/O | Distributed I/O System | Remote I/O for control systems | Works with AC800M series |

| CP600 HMI | Human-Machine Interface | Operator interface panels | Ideal front-end for drive and tension systems |

Excellent PLC

Excellent PLC