| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

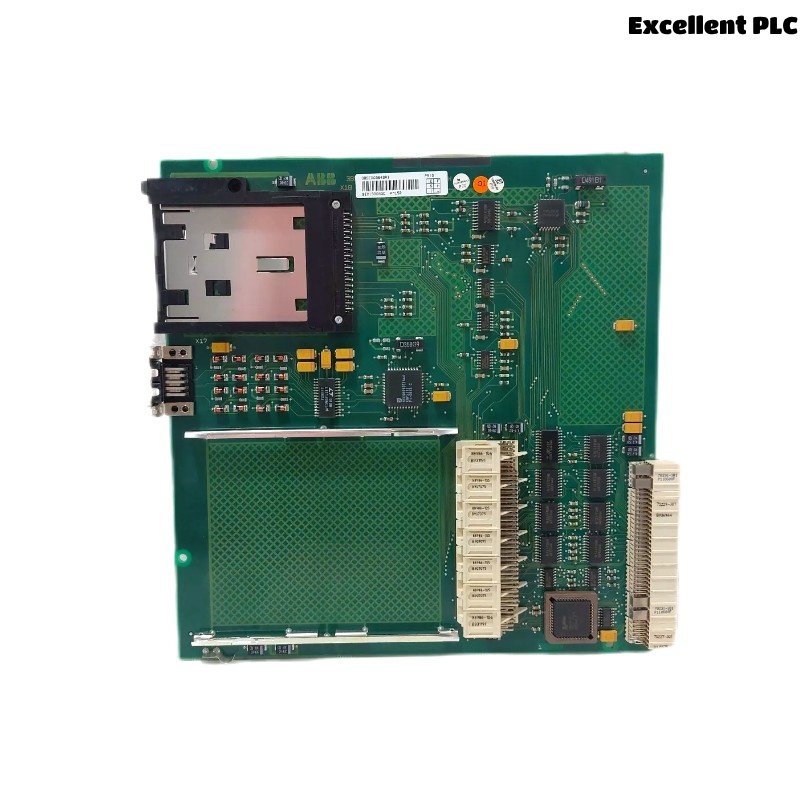

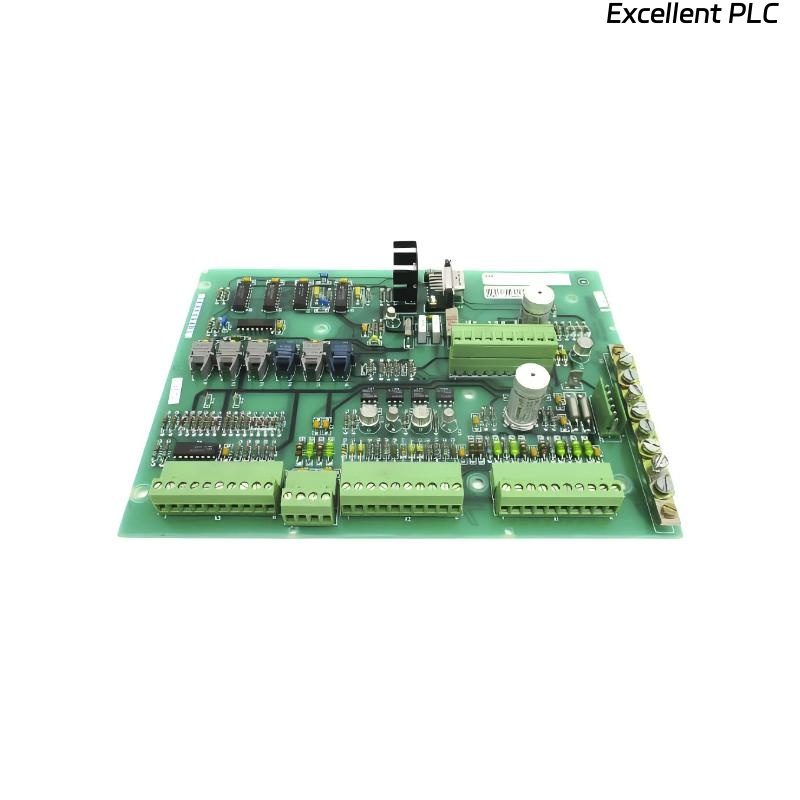

Product Introduction

The ABB PM152 3BSE003643R1 is a robust and versatile CPU board designed for the Advant Controller 31 platform. Positioned as a mid-tier controller in ABB’s distributed control system (DCS) portfolio, the PM152 delivers enhanced computing power, expanded memory, and reliable communication interfaces. It serves as the control core of industrial automation setups, executing control logic, managing I/O signals, and facilitating system communication.

The PM152 is ideal for medium- to large-scale automation tasks requiring real-time responsiveness, diagnostics, and communication with supervisory systems or HMI devices. It integrates seamlessly into both existing and new Advant installations, ensuring long-term support and system expansion capabilities.

Technical Specifications

| Parameter | Details |

|---|---|

| Model Name | PM152 |

| Part Number | 3BSE003643R1 |

| Product Type | CPU Board Card / Controller Module |

| System Compatibility | Advant Controller 31 |

| Processor Type | Embedded 32-bit Processor |

| RAM Memory | 1 MB RAM |

| Flash Memory | 512 KB |

| Supported Protocols | MODBUS, Advant Fieldbus 100, RS232/485 |

| Operating Modes | Cyclic, Interrupt-Driven |

| Communication Ports | RS232, RS485, Advant Fieldbus 100 |

| Mounting Method | Base unit / Rack Mounting |

| Power Supply | 5 VDC |

| Operating Temperature | 0°C to +60°C |

| Storage Temperature | -40°C to +85°C |

| Humidity Tolerance | 5%–95%, Non-condensing |

| Dimensions (L×W×H) | 24 × 125 × 120 mm |

| Weight | 0.35 kg |

Applications

The ABB PM152 is widely used in the following industrial automation scenarios:

-

Chemical and Petrochemical Plants – For precision control in reaction, blending, and safety subsystems

-

Power Generation – Turbine control, switchgear management, and auxiliary process regulation

-

Water Treatment Facilities – Valve and pump automation with continuous monitoring

-

Manufacturing Lines – Process logic control for batch and continuous production

-

Metals and Mining – Drives and process interlocking in steel and aluminum production

-

Pharmaceutical Industry – Batch process automation and quality control

Product Advantages

-

Upgraded Processing Power – Compared to the PM151, the PM152 offers a faster processor and greater memory, ideal for complex control strategies.

-

Integrated Fieldbus Interfaces – Supports communication via Advant Fieldbus and RS232/RS485, allowing seamless integration with I/O and SCADA systems.

-

Modular Expandability – Fully compatible with other Advant Controller 31 modules for system scalability.

-

Enhanced Diagnostics – On-board LEDs and status feedback simplify troubleshooting and system analysis.

-

Reliable Real-Time Execution – Ensures deterministic response in time-critical control applications.

-

Long Lifecycle – Industrial-grade build quality ensures long service life in demanding environments.

-

Compact Footprint – Space-saving design enables installation in dense control cabinets.

-

Easy Configuration – Supported by ABB’s engineering tools such as Advant Control Builder and Composer.

-

Backward Compatibility – Can be used as a functional upgrade or replacement for earlier CPU versions.

-

Global Availability – Supported by ABB’s global network of service, support, and spare parts.

Frequently Asked Questions (FAQ)

-

What is the primary difference between PM151 and PM152?

The PM152 offers higher memory and processing power, making it suitable for more complex applications. -

Can PM152 be installed in existing Advant Controller 31 systems without modification?

Yes, it is fully backward-compatible with Advant hardware. However, firmware alignment is recommended. -

Does the PM152 support redundant CPU configurations?

Redundancy is not built-in, but it can be implemented at a system level using additional ABB modules. -

What tools are required to configure the PM152?

ABB’s Composer and Advant Control Builder software packages are typically used for programming and diagnostics. -

Can I upgrade firmware on the PM152 in the field?

Yes, firmware upgrades can be applied using serial communication and ABB’s software tools. -

Is the PM152 affected by electromagnetic interference?

It is protected by industrial-grade shielding, but proper grounding and cabinet design are essential. -

How long can the PM152 operate continuously without maintenance?

With normal industrial conditions, it can operate over 10 years with only routine preventive maintenance. -

Can I use third-party I/O modules with PM152?

ABB recommends only certified Advant-compatible modules for system integrity and safety. -

What happens if the PM152 fails during operation?

The system enters fail-safe mode. Diagnostics via LED and ABB tools help identify root causes quickly. -

Is the PM152 suitable for remote I/O configurations?

Yes, it supports remote I/O through Advant Fieldbus 100 and standard communication ports.

Related or Same Series Models

| Model | Description | Platform | Weight | Dimensions (mm) |

|---|---|---|---|---|

| PM151 3BSE003642R1 | Base CPU with standard memory | Advant Controller 31 | 0.42 kg | 160 × 100 × 35 |

| PM153 3BSE003644R1 | Advanced CPU with diagnostics and flash | Advant Controller 31 | 0.48 kg | 160 × 100 × 35 |

| DI810 | Digital Input Module, 16 channels | S800 I/O | 0.33 kg | 115 × 81 × 32 |

| DO810 | Digital Output Module, 16 channels | S800 I/O | 0.34 kg | 115 × 81 × 32 |

| TU810V1 | Terminal Unit for S800 modules | S800 I/O | 0.30 kg | 130 × 100 × 40 |

| TB840A | Bus terminator with system integration | S800 I/O | 0.20 kg | 80 × 60 × 25 |

Popular ABB Automation Models (Same Brand)

| Model | Description | Series | Weight | Dimensions (mm) |

|---|---|---|---|---|

| PM864AK01 | High-performance CPU Module | AC 800M | 0.50 kg | 140 × 100 × 40 |

| CI854AK01 | Profibus Communication Interface | AC 800M | 0.45 kg | 120 × 80 × 30 |

| AI810 | 8-channel Analog Input Module | S800 I/O | 0.30 kg | 115 × 81 × 32 |

| AO845A | 4-channel Analog Output Module | S800 I/O | 0.32 kg | 115 × 81 × 32 |

| DO820 | 8-channel Digital Output Module | S800 I/O | 0.34 kg | 115 × 81 × 32 |

| CI840A | Communication Interface Module | S800 I/O | 0.38 kg | 115 × 81 × 32 |

Excellent PLC

Excellent PLC