| Company Information | ||||||||

| sales@xmjzjsgs.com | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

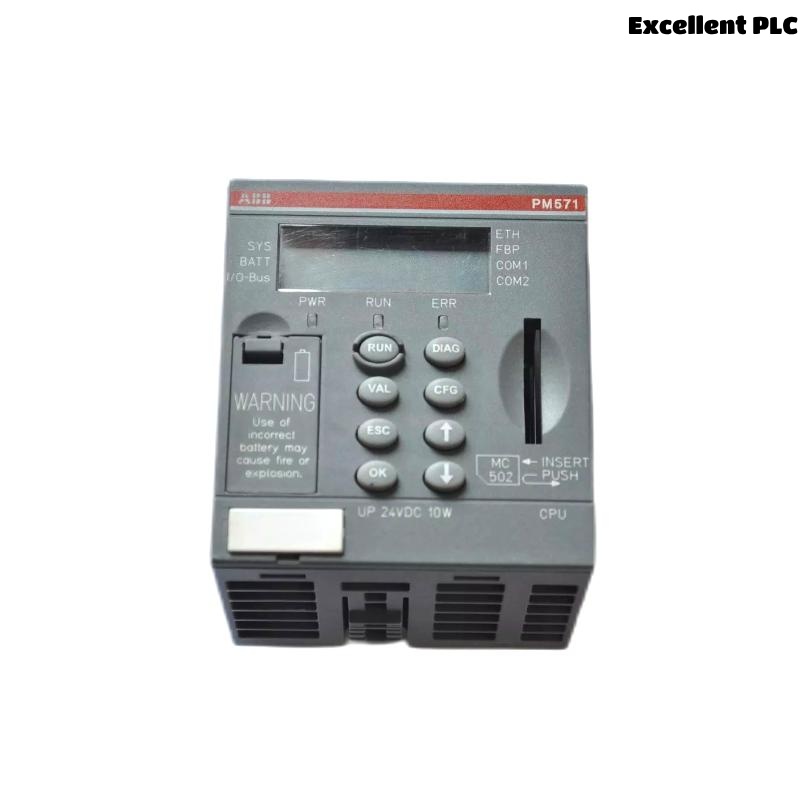

The ABB PM571 1SAP130100R0100 CPU Module is a compact, versatile, and high-performance controller in the ABB AC500 PLC family. This CPU is designed to deliver powerful control performance within space-constrained or distributed industrial automation systems. Supporting a broad array of fieldbus protocols, high-speed processing, and flexible programming environments, the PM571 serves as the core of many reliable and scalable automation solutions.

With integrated onboard I/O and modular expansion capabilities, the PM571 CPU can be used in both stand-alone applications and complex distributed control systems (DCS). It supports multiple IEC 61131-3 programming languages through ABB Automation Builder software and is a trusted component in demanding sectors such as machine automation, utilities, energy, transportation, water management, and building automation.

The PM571 CPU module also provides real-time communication, multi-tasking capability, and extensive diagnostics that make it ideal for critical control applications requiring both high availability and flexibility.

Product Specifications

| Parameter | Specification |

|---|---|

| Model Number | PM571 1SAP130100R0100 |

| Product Type | CPU Module |

| System Platform | ABB AC500 PLC family |

| Processor | 32-bit RISC CPU |

| Program Memory | 1 MB |

| Data Memory | 512 KB |

| Retentive Memory | 256 KB |

| Real-Time Clock | Yes (with battery backup) |

| Supported Programming Languages | IEC 61131-3 (LD, FBD, ST, IL, SFC) |

| Communication Ports | 1 x RS-232, 1 x USB, 1 x Ethernet (optional expansion), CANopen (optional) |

| Fieldbus Support | Modbus TCP, Modbus RTU, CANopen (with module) |

| Number of Local I/O Modules | Up to 10 S500 I/O modules |

| Digital I/O Onboard | 10 digital inputs, 6 digital outputs |

| Analog I/O Onboard | 2 analog inputs, 2 analog outputs |

| Cycle Time | ~1 ms typical |

| Task Handling | Multitasking with priorities |

| Diagnostic Features | Extensive, integrated system monitoring |

| Firmware Upgrade | Yes, via USB or Ethernet |

| Power Supply Voltage | 24 VDC ±20% |

| Power Consumption | 5 W |

| Operating Temperature Range | 0°C to +60°C |

| Storage Temperature Range | -25°C to +70°C |

| Humidity Range | 5% to 95% non-condensing |

| Module Dimensions (H x W x D) | 62 × 76 × 67.5 mm |

| Weight | 0.135 kg |

| Mounting Method | DIN rail mounting |

| Certifications | CE, cULus, RoHS, ATEX Zone 2 certified |

Applications

-

Machine Control: Packaging machines, material handling equipment, CNC machines

-

Water & Wastewater: Pump stations, treatment plants, distributed water networks

-

HVAC & Building Automation: Intelligent control of heating, ventilation, lighting, and security systems

-

Infrastructure: Smart transportation hubs, tunnels, ports, airports

-

Renewable Energy: Wind turbines, solar energy control, energy storage systems

-

Food & Beverage: Batch control, bottling, packaging, CIP systems

-

Oil & Gas (non-hazardous areas): Skid-mounted systems, utilities monitoring

-

Textile & Printing: Precise control of production machines and web handling systems

-

Power Distribution: Substation automation, switchgear control

-

General Factory Automation: Cost-effective control for small to mid-size applications

Product Advantages

-

Compact Design: Space-saving form factor suitable for small cabinets and distributed I/O

-

Flexible Connectivity: Supports a wide range of fieldbus and Ethernet protocols

-

Integrated I/O: Onboard digital and analog I/O simplify control architectures

-

High Reliability: Engineered for long operational life in industrial environments

-

Fast Response: High-speed CPU enables real-time control and fast machine cycles

-

Modular & Expandable: Supports additional S500 I/O modules for project scalability

-

Diagnostic Capability: Integrated system diagnostics improve maintenance and troubleshooting

-

Easy Programming: Uses widely adopted IEC 61131-3 standard programming

-

Worldwide Compliance: Certified for global industrial applications

-

Energy Efficient: Low power consumption reduces operating costs

Frequently Asked Questions (FAQ)

-

What is the processing speed of the PM571 CPU?

The typical cycle time is approximately 1 ms, depending on program complexity. -

Does the PM571 include onboard I/O?

Yes, it includes 10 digital inputs, 6 digital outputs, and 2 analog inputs/outputs. -

Can the CPU be used in harsh industrial environments?

Yes, it is rated for 0°C to +60°C operation and certified for ATEX Zone 2 applications. -

What programming tools are supported?

ABB Automation Builder software supports IEC 61131-3 standard programming. -

Does the CPU module support redundancy?

No, PM571 does not support CPU redundancy; higher-end AC500 models do. -

Can I expand the communication ports?

Yes, optional modules allow adding Ethernet or CANopen ports. -

How many I/O modules can be connected?

Up to 10 S500 I/O modules can be added locally to the CPU. -

Is there a built-in real-time clock?

Yes, the CPU has an RTC with battery backup. -

Can firmware be upgraded?

Yes, firmware can be upgraded via USB or Ethernet. -

What fieldbus protocols does it support?

It supports Modbus RTU, Modbus TCP, and CANopen (with expansion module).

Recommended Related Models (Same Series or Similar)

| Model Number | Description | Notes |

|---|---|---|

| PM554-ETH | Compact AC500 CPU with Ethernet | Ethernet included |

| PM556-TP | Mid-range CPU with TP port | Suitable for OEM machines |

| PM572 | Higher memory version of PM571 | More memory for complex apps |

| PM583-ETH | High-performance AC500 CPU with Ethernet | For demanding control |

| PM585 | Large memory, advanced CPU | Complex, scalable systems |

| PM595 | High-end AC500 CPU with multi-core processor | Advanced process control |

Popular ABB Automation Models (Same Brand)

| Model Number | Description | Application |

|---|---|---|

| AC500 PM595 | Flagship high-end CPU | Process & hybrid control |

| AC500 PM583-ETH | High-performance compact CPU | Factory automation |

| CI581-DP | Profibus DP communication module | Profibus integration |

| DO561 1TNE968902R2201 | Digital Output Module, 16 outputs | Digital field device control |

| AI581 1SAP180200R0001 | Analog Input Module | Process monitoring |

| TB511-ETH | Ethernet Remote I/O Base | I/O expansion for AC500 |

Excellent PLC

Excellent PLC