| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

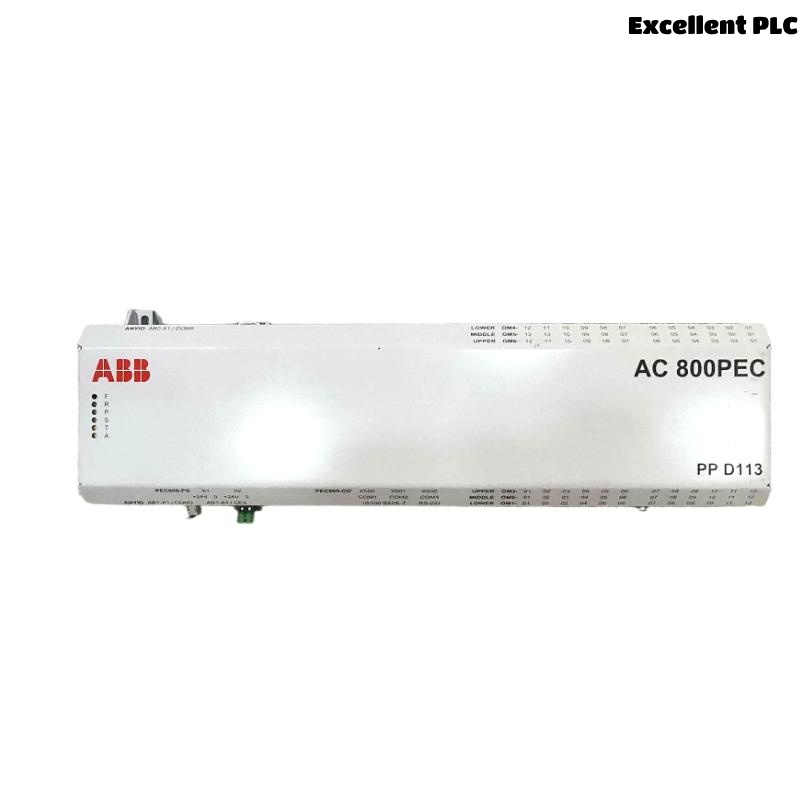

The ABB PP D113 3BHE023784R2634 AC800PEC controller is an advanced, high-performance controller designed for complex industrial automation and control applications. This controller is part of ABB’s AC800PEC series, which is known for its exceptional flexibility, scalability, and robust processing power. The AC800PEC controller is designed to handle demanding process control environments in industries such as oil and gas, chemical, pharmaceuticals, energy, and manufacturing.

With a powerful processor, a variety of input/output options, and support for multiple communication protocols, the AC800PEC controller is capable of managing real-time data processing, automating critical tasks, and optimizing system performance. Its modular design allows for easy scalability, enabling businesses to adapt their systems as their requirements evolve.

Product Parameters

| Parameter | Specification |

|---|---|

| Model | PP D113 3BHE023784R2634 |

| Dimensions | 150 x 450 x 100 mm |

| Weight | 2.8 kg |

| Control System | AC800PEC |

| Processor | 500 MHz Processor |

| Input/Output Channels | 32 I/O Channels |

| Communication Ports | Ethernet, Serial, I/O |

| Power Supply | 24 V DC |

| Environmental Conditions | -20°C to 60°C |

| Mounting | DIN Rail Mounting |

Product Applications

The ABB PP D113 3BHE023784R2634 AC800PEC controller is designed for a wide range of applications, including:

-

Process Control Systems: The AC800PEC is ideal for industries that require precise control over continuous processes, such as chemical production, water treatment, and energy distribution.

-

Manufacturing Automation: It helps streamline manufacturing lines, ensuring that all equipment works in harmony to produce high-quality products at maximum efficiency.

-

Oil and Gas Industry: It is used to monitor and control complex systems involved in drilling, refining, and transportation of oil and gas products.

-

Pharmaceutical Manufacturing: In the pharmaceutical industry, the controller is used to manage production processes and ensure compliance with regulatory standards.

-

Energy Management: The AC800PEC is also used in power generation plants and renewable energy systems to optimize energy production and distribution.

-

Building Automation Systems: With its communication capabilities, the AC800PEC can be used to control heating, ventilation, air conditioning (HVAC), lighting, and other systems in commercial and industrial buildings.

Product Advantages

-

High Processing Power: Equipped with a 500 MHz processor, the AC800PEC controller can process complex control algorithms in real time, ensuring optimal system performance.

-

Modular and Scalable: Its modular design allows for easy integration of additional I/O modules and communication ports, providing flexibility for future expansions.

-

Reliable Communication: With support for multiple communication protocols, including Ethernet and serial communication, it ensures reliable data exchange between the controller and other devices in the system.

-

Robust Design: The controller is built to withstand extreme conditions, making it ideal for industrial environments where reliability and durability are crucial.

-

Energy Efficiency: The AC800PEC is designed to optimize energy consumption, ensuring that systems run efficiently without unnecessary power consumption.

-

User-Friendly Interface: The controller’s intuitive programming and configuration interface make it easy to set up and maintain, reducing downtime and operational costs.

FAQ (Frequently Asked Questions)

1. What is the primary function of the ABB PP D113 3BHE023784R2634 AC800PEC controller?

The AC800PEC controller is used to manage and control complex industrial processes, including automation, monitoring, and optimization of control systems.

2. How many I/O channels does the ABB PP D113 support?

The controller supports 32 I/O channels, allowing for the connection of a wide variety of sensors, actuators, and other devices.

3. What is the operating temperature range of the AC800PEC controller?

The AC800PEC controller is designed to operate in environments with temperatures ranging from -20°C to 60°C.

4. What type of power supply is required for the ABB PP D113 controller?

The controller requires a 24 V DC power supply to function properly.

5. How fast is the processing power of the ABB PP D113 controller?

The controller is equipped with a 500 MHz processor, providing high-speed processing for complex control applications.

6. What are the main communication options available with the AC800PEC controller?

The controller supports Ethernet, serial, and I/O communication, ensuring flexibility in connecting to various devices and systems.

7. How is the ABB PP D113 controller mounted?

The AC800PEC controller is designed for easy mounting on a DIN rail, a standard mounting method for industrial automation equipment.

8. Is the ABB PP D113 controller suitable for process industries?

Yes, it is specifically designed for process control systems and is widely used in industries such as chemical, energy, and pharmaceuticals.

9. Can the ABB PP D113 be used in outdoor environments?

While the controller can operate in harsh conditions, it should be installed in a suitable enclosure if used in outdoor environments to protect it from weather conditions.

10. How can the ABB PP D113 controller help with energy efficiency?

The AC800PEC controller is designed to optimize the performance of control systems, reducing unnecessary power consumption while ensuring that processes run efficiently.

Recommended Models

Same Series or Related Models

| Model | Description | Key Parameters |

|---|---|---|

| PM891K01 | Process Control Module | Dimensions: 200 x 400 x 100 mm, Weight: 4.0 kg, Input/Output: Digital/Analog, Voltage: 24V DC |

| PM891K02 | Enhanced Control Module | Dimensions: 200 x 400 x 100 mm, Weight: 4.1 kg, Input/Output: Digital/Analog, Voltage: 24V DC |

| PM902F | Multi-function Process Control Module | Dimensions: 210 x 410 x 110 mm, Weight: 4.2 kg, Input/Output: Digital/Relay, Voltage: 24V DC |

| PM891K03 | Voltage Regulation Control Module | Dimensions: 200 x 400 x 100 mm, Weight: 4.0 kg, Input/Output: Analog/Digital, Voltage: 48V DC |

| PM891K04 | Temperature Control Module | Dimensions: 200 x 400 x 100 mm, Weight: 4.1 kg, Input/Output: Digital/Analog, Voltage: 12V DC |

| PM902G | Field Control Module | Dimensions: 210 x 410 x 110 mm, Weight: 4.3 kg, Input/Output: Digital/Relay, Voltage: 48V DC |

Same Brand – Popular Models

| Model | Description | Key Parameters |

|---|---|---|

| PMC916 | Process Control Module | Dimensions: 180 x 350 x 90 mm, Weight: 3.5 kg, Input/Output: Digital/Analog, Voltage: 24V DC |

| PMSI121 | Industrial Automation Module | Dimensions: 200 x 400 x 100 mm, Weight: 3.6 kg, Input/Output: Digital/Analog, Voltage: 24V DC |

| PMSK106A | Flexible Control Module | Dimensions: 190 x 380 x 90 mm, Weight: 3.4 kg, Input/Output: Analog/Digital, Voltage: 48V DC |

| PMC917 | Advanced Process Control Module | Dimensions: 180 x 350 x 90 mm, Weight: 3.5 kg, Input/Output: Digital/Relay, Voltage: 24V DC |

| PMSI122 | Multi-channel Control Module | Dimensions: 200 x 400 x 100 mm, Weight: 3.7 kg, Input/Output: Digital/Analog, Voltage: 48V DC |

| PMSK107A | Voltage Regulation Control Module | Dimensions: 190 x 380 x 90 mm, Weight: 3.6 kg, Input/Output: Digital/Relay, Voltage: 12V DC |

Excellent PLC

Excellent PLC