| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

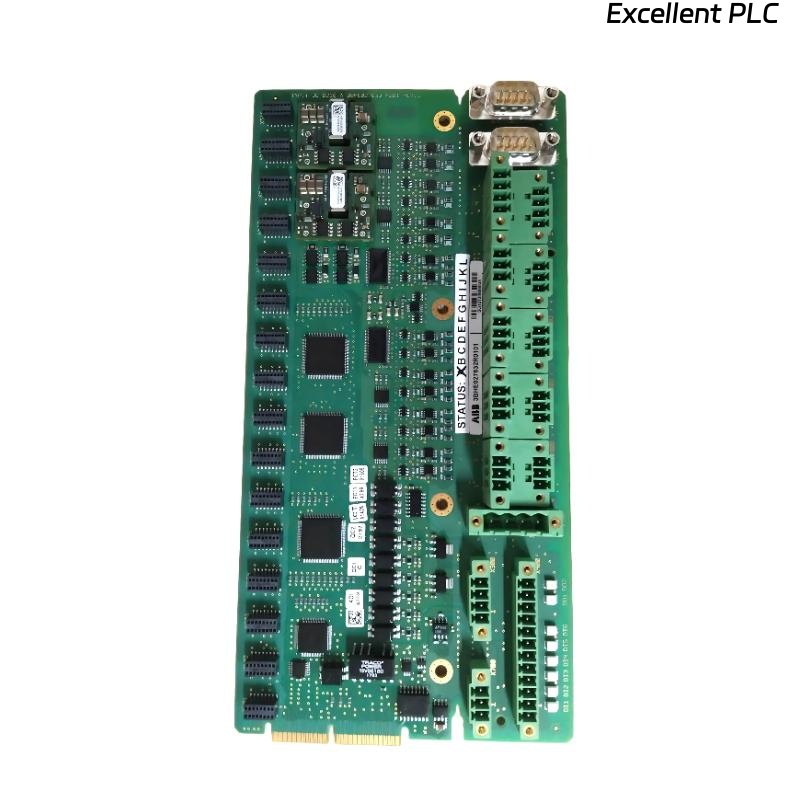

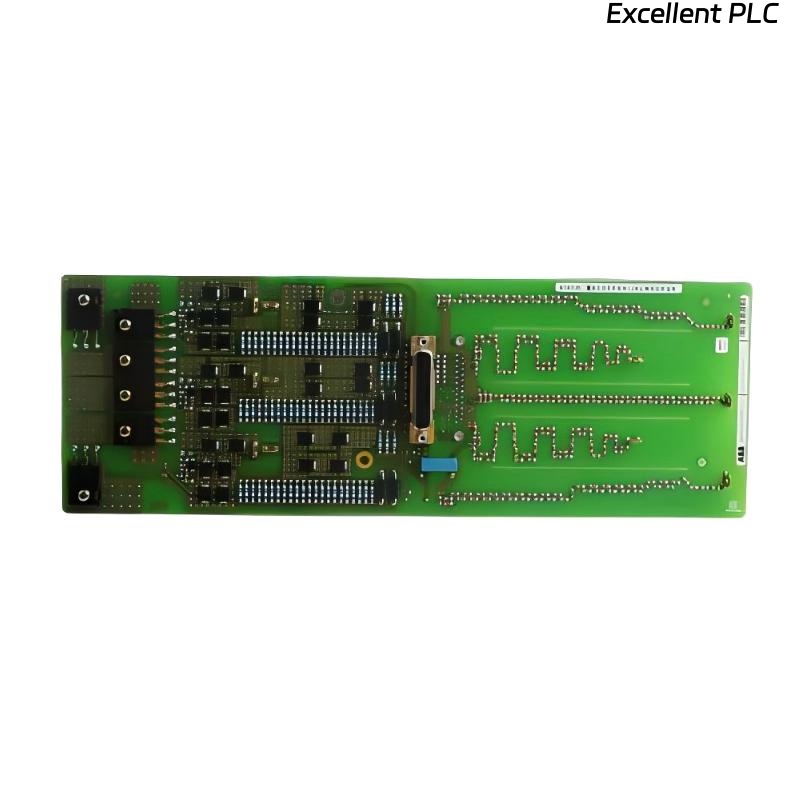

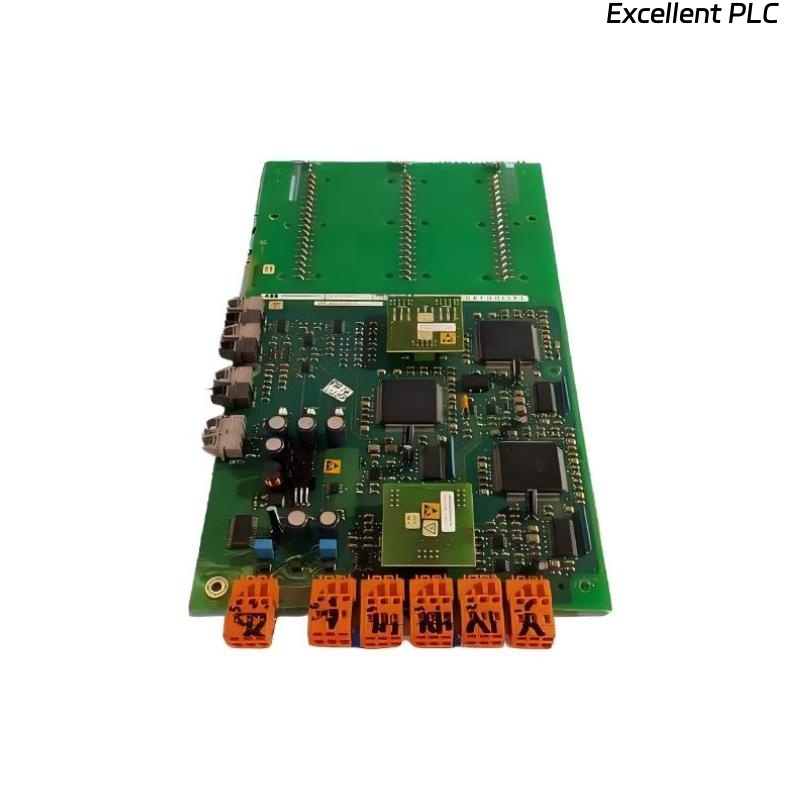

The ABB PP D114 B1022 3BHE020570R1022 AC800 Control Module is a high-performance processor unit designed for use within ABB’s AC800 series distributed control systems (DCS). It functions as the core computational and coordination unit for industrial process automation, providing robust control performance, fast communication, and reliable integration with a wide range of ABB I/O and communication modules.

This control module incorporates a high-speed 32-bit industrial processor that ensures deterministic real-time control for continuous and batch processes. It is equipped with redundant communication ports, advanced diagnostic capabilities, and an extended temperature range, allowing it to operate in harsh industrial environments such as power plants, chemical refineries, steel manufacturing facilities, and offshore oil platforms.

Built to meet the highest reliability standards, the PP D114 B1022 module offers fault-tolerant operation, high electromagnetic immunity, and superior noise resistance. Its modular design enables seamless system expansion and easy integration with ABB’s Control Builder software suite for configuration, programming, and system monitoring.

Technical Specifications

| Parameter | Description |

|---|---|

| Product Model | PP D114 B1022 |

| Part Number | 3BHE020570R1022 |

| Series | ABB AC800 Control System |

| Processor Type | 32-bit high-performance industrial microcontroller |

| Clock Speed | 400 MHz |

| Memory (RAM) | 64 MB SDRAM |

| Flash Memory | 32 MB |

| Communication Interfaces | Ethernet, PROFIBUS-DP, Modbus RTU/TCP, CAN bus |

| Supported Protocols | TCP/IP, SNMP, ABB proprietary protocol |

| Number of Supported I/O Channels | Up to 1024 (depending on system configuration) |

| Operating Voltage | 24 VDC nominal (18–30 VDC range) |

| Power Consumption | 12 W (typical) |

| Protection Features | ESD, short-circuit, overvoltage, and reverse polarity protection |

| Mounting Type | DIN-rail or backplane mounted |

| Cooling Method | Natural convection (no fan required) |

| Housing Material | Aluminum alloy with reinforced connectors |

| Operating Temperature Range | -25°C to +70°C |

| Storage Temperature Range | -40°C to +85°C |

| Humidity Tolerance | 5% to 95% (non-condensing) |

| Vibration Resistance | 10–150 Hz, 0.5 mm amplitude |

| Software Compatibility | ABB Control Builder M, AC800M system tools |

| System Redundancy | Supported (redundant configuration optional) |

| Dimensions | 450 x 100 x 150 mm |

| Weight | 2.8 kg |

Product Applications

The PP D114 B1022 3BHE020570R1022 module is designed to provide flexible and precise control across a wide range of process industries. It is used as a core control unit in distributed control architectures where reliability, performance, and integration flexibility are critical.

-

Power Generation: Controls turbine operations, synchronization systems, and boiler automation.

-

Oil & Gas Processing: Manages refining operations, compressor stations, and offshore platform control.

-

Chemical & Petrochemical Industries: Coordinates reactors, distillation columns, and process safety systems.

-

Metallurgical & Mining Applications: Provides real-time control for furnaces, rolling mills, and cooling systems.

-

Pulp & Paper Industry: Handles process loops for pulp refining, paper drying, and machine automation.

-

Marine & Offshore Automation: Controls propulsion, navigation, and energy management systems.

This module’s deterministic control behavior, multi-protocol communication, and high fault tolerance make it ideal for mission-critical automation processes that require continuous 24/7 operation.

Product Advantages

-

High-Speed Processing Performance

The powerful 32-bit processor ensures rapid execution of control algorithms, suitable for both continuous and batch process control. -

Comprehensive Communication Support

Offers multiple communication options, including Ethernet, PROFIBUS, and Modbus, allowing seamless integration into complex control networks. -

Rugged and Durable Design

Built with industrial-grade materials and conformal coating for protection against vibration, humidity, and dust. -

Scalable Architecture

The modular AC800 platform allows for flexible system expansion with additional I/O and communication modules. -

Advanced Diagnostic Tools

Provides system self-checks, fault logging, and LED status indicators for efficient troubleshooting. -

Redundancy and Reliability

Supports redundant operation for high-availability systems, minimizing downtime during maintenance or faults. -

Easy Integration and Configuration

Fully compatible with ABB’s Control Builder M software, simplifying configuration, logic programming, and online modifications. -

Low Power Consumption

Optimized design ensures efficient operation and reduced heat generation.

FAQ

-

What is the main function of the ABB PP D114 B1022 module?

It acts as the main processor and control unit within the AC800 control system, managing control logic, data communication, and coordination among connected I/O modules. -

Which communication interfaces are available on this module?

It supports Ethernet, PROFIBUS-DP, Modbus RTU/TCP, and CAN bus interfaces for seamless system connectivity. -

Does this module support redundancy operation?

Yes, the PP D114 B1022 can operate in a redundant configuration to improve reliability and system uptime. -

How is programming performed for this module?

Programming and configuration are done through ABB’s Control Builder M software, which supports IEC 61131-3 standard languages. -

Can it communicate with third-party devices?

Yes, thanks to its open communication protocols such as Modbus and TCP/IP, it can communicate with third-party PLCs and devices. -

What diagnostic features are available?

It includes self-diagnostic functions, error reporting, and LED status indicators for real-time operational feedback. -

How does the module handle I/O expansion?

It supports expansion through ABB I/O modules connected via the system bus, allowing scalable system architecture. -

Is the module suitable for harsh environments?

Yes, it features high vibration tolerance, wide temperature range, and protection against electrical disturbances. -

How can firmware be updated?

Firmware can be safely updated using ABB’s system tools through the Ethernet service interface. -

What power supply range does it support?

It operates within an 18–30 VDC range, providing flexibility for industrial power systems.

Recommended Related Models (Same Series or Equivalent)

| Model | Description | Series | Weight |

|---|---|---|---|

| PP D113 B03-26-100100 3BHE023584R2625 | Standard AC800 Control Processor | AC800 | 0.88 kg |

| PP D113 B03-23-111615 3BHE023584R2365 | High-Reliability Control Module | AC800 | 0.85 kg |

| PP D115 A02 3BHE017628R0002 | Process Controller Unit | AC800 | 0.82 kg |

| PP D103 B03 3BHE020455R0003 | Logic Control Unit | AC800 | 0.84 kg |

| PP D200 A101 3BHE019633R0101 | Advanced System Controller | AC800 | 0.89 kg |

| PP D234 A101 3BHE024820R0101 | Control Interface Module | AC800 | 0.90 kg |

Popular ABB Models (Same Brand)

| Model | Description | Product Type | Weight |

|---|---|---|---|

| PM864AK01 3BSE018161R1 | Main Processor Unit | DCS Controller | 1.05 kg |

| PM866AK02 3BSE050198R1 | High-Performance Processor | Controller Module | 1.10 kg |

| CI854AK01 3BSE025961R1 | Fieldbus Communication Adapter | Interface Module | 0.75 kg |

| AI810 3BSE008516R1 | Analog Input Module | I/O Module | 0.65 kg |

| DI810 3BSE008508R1 | Digital Input Module | I/O Module | 0.60 kg |

| DO810 3BSE008510R1 | Digital Output Module | I/O Module | 0.62 kg |

Excellent PLC

Excellent PLC