| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

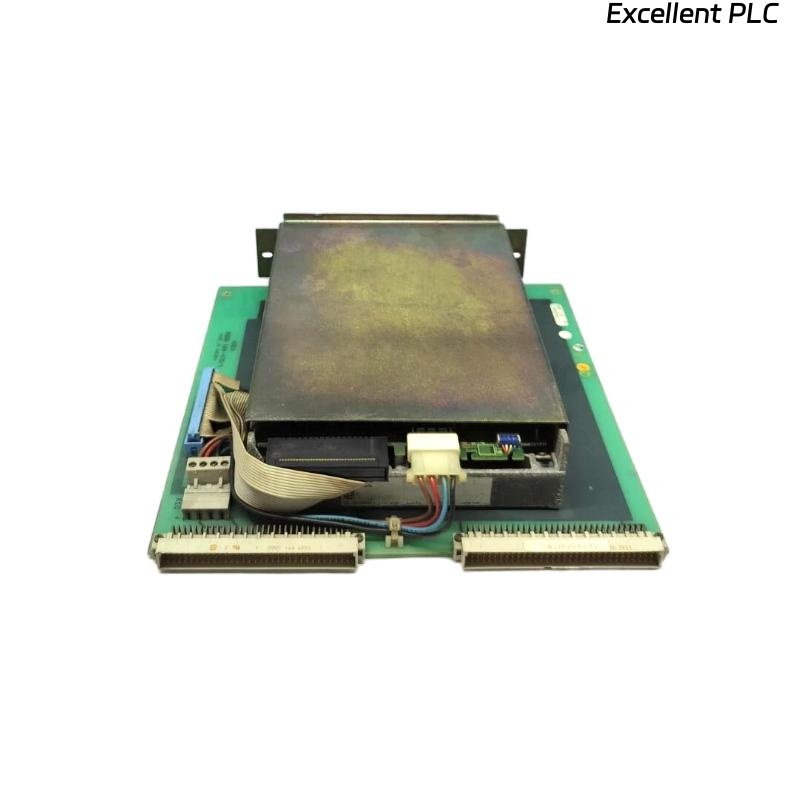

The ABB PP835A 3BSE042234R2 Operation Panel is a high-performance, industrial-grade Human-Machine Interface (HMI) developed by ABB for seamless interaction between operators and automated systems. As part of ABB’s PP800 series, the PP835A delivers a robust solution for real-time process visualization, control feedback, and data communication in demanding industrial environments.

This panel supports integration with various ABB control systems, particularly the AC 800M and 800xA automation platforms. With a sleek design, enhanced processing capability, and a reliable operator interface, it is ideally suited for control room applications as well as plant-floor installations. The panel is specifically designed to withstand rugged industrial conditions while providing clear, consistent user interaction via its tactile interface and high-resolution display.

Product Specifications

| Parameter | Details |

|---|---|

| Model | PP835A |

| Order Code | 3BSE042234R2 |

| Manufacturer | ABB |

| Series | PP800 Series |

| Display Type | TFT LCD |

| Display Size | 12.1 inches |

| Touchscreen | No (Operated via pushbuttons) |

| Backlight Type | LED |

| Interface Ports | RS-232, RS-485, Ethernet (RJ45) |

| Supported Protocols | MODBUS, PROFIBUS, Ethernet/IP, ABB proprietary protocols |

| Input Voltage | 24 VDC |

| Power Consumption | Approximately 25 W |

| Protection Rating | Front: IP65, Rear: IP20 |

| Material | Industrial aluminum enclosure |

| Mounting Type | Panel mount |

| Operating Temperature | 0°C to +50°C |

| Storage Temperature | -20°C to +70°C |

| Dimensions (W x H x D) | 219 x 154 x 6 mm |

| Weight | 1.2 kg |

| Certifications | CE, UL, RoHS, cUL |

| System Compatibility | AC 800M, Freelance, 800xA |

Product Applications

The ABB PP835A is widely deployed across multiple industrial sectors due to its reliability and compatibility with advanced control systems. Typical application areas include:

-

Power Generation Facilities: Local monitoring and control of turbines, substations, and generator systems.

-

Oil & Gas Sector: Interface for pipeline monitoring, gas compression, and refining operations.

-

Metals and Mining: Used for HMI visualization in smelting, processing, and conveyor control systems.

-

Pulp and Paper Mills: Offers efficient control over drying, pressing, and cutting equipment.

-

Food and Beverage Manufacturing: Ensures precise control of packaging and processing machinery.

-

Chemical and Petrochemical Plants: Ideal for batch process control and safety system interfaces.

The PP835A is particularly useful in centralized control rooms and on-machine operator terminals, ensuring real-time responsiveness and minimal downtime.

Product Advantages

-

Robust Design: Built for harsh industrial environments, offering long operational life with minimal maintenance.

-

High Visual Clarity: 12.1” TFT screen with high brightness and resolution ensures visibility under varied lighting.

-

Flexible Communication: Supports multiple industrial protocols for integration into existing systems.

-

Secure Front Panel: IP65-rated front ensures protection against water jets and dust.

-

Seamless ABB Integration: Fully compatible with ABB’s 800xA and AC 800M platforms for efficient deployment.

-

Fast Setup & Commissioning: Easy to install with standardized panel cutouts and ABB’s configuration tools.

-

Low Power Consumption: Energy-efficient, consuming just 25W while delivering high processing capability.

-

Longevity & Availability: Backed by ABB’s long-term support and parts availability roadmap.

Frequently Asked Questions (FAQ)

-

Q: What control systems does the PP835A support?

A: The panel is optimized for ABB’s AC 800M and 800xA systems, but it can also work with Freelance controllers. -

Q: Is this panel touchscreen-based?

A: No, it uses tactile pushbuttons for user input. -

Q: Can it be used in outdoor environments?

A: The panel is not weatherproof but can be used outdoors when installed in a protected enclosure. -

Q: What is the main difference between PP835A and PP826A?

A: The PP835A has a larger 12.1” display and higher processing capabilities compared to the 10.4” PP826A. -

Q: Does the panel require special software to configure?

A: Yes, configuration is typically done using ABB’s Automation Builder or Panel Builder tools. -

Q: What are the communication options available?

A: The panel supports Ethernet, RS-232, RS-485, and various industrial protocols like MODBUS and PROFIBUS. -

Q: Is this device RoHS compliant?

A: Yes, it is certified for RoHS, CE, and other industrial compliance standards. -

Q: Can it store and log process data locally?

A: It depends on the configuration, but typically it serves as an interface and does not store large data logs independently. -

Q: What is the service life of this panel?

A: The PP835A is designed for 10–15 years of continuous industrial use under recommended conditions. -

Q: Can I replace an older panel (like PP820A) with the PP835A?

A: Yes, though minor panel cutout adjustments may be required; protocol compatibility ensures functional replacement.

Recommended Related Models (Same Series or Function)

| Model | Description | Display Size | Touchscreen | System Compatibility |

|---|---|---|---|---|

| PP826A 3BSE042244R3 | Compact operator panel with IP65 front | 10.4” | No | AC800M, 800xA |

| PP865A 3BSE042237R1 | Enhanced display with USB support | 10.4” | Yes | AC800M, MOD300 |

| PP877K 3BSE092275R1 | Small form HMI for tight spaces | 7” | Yes | Freelance, AC500 |

| PP820A 3BSE041735R1 | Standard HMI for basic visualization tasks | 8.4” | No | 800xA, Advant Controller |

| CP635 1SAP500600R0001 | Touch panel for AC500 PLCs | 5.7” | Yes | AC500, MODBUS |

| CP657 1SAP500900R0001 | Mid-range panel with Ethernet support | 7” | Yes | AC500, Freelance |

Popular ABB Models (Widely Used Across Industries)

| Model | Function | Application | Key Features |

|---|---|---|---|

| AC800M PM865K02 | CPU controller | DCS systems | Dual processor, high memory capacity |

| CI854AK01 3BSE030220R1 | PROFIBUS communication module | Field device interfacing | Redundancy support, high-speed I/O |

| PM573-ETH | Compact PLC with Ethernet | Machine automation | Web server, USB programming |

| CP600-PRO-10 | High-end touch HMI | Advanced operator interface | Multi-touch, gesture control |

| TU810V1 | Terminal unit for S800 I/O | Modular I/O setup | 8 channels, DIN rail mountable |

| 07KT98 GJR5253100R3260 | I/O controller module | Advant Master system | Redundant I/O and robust communication |

Excellent PLC

Excellent PLC