| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

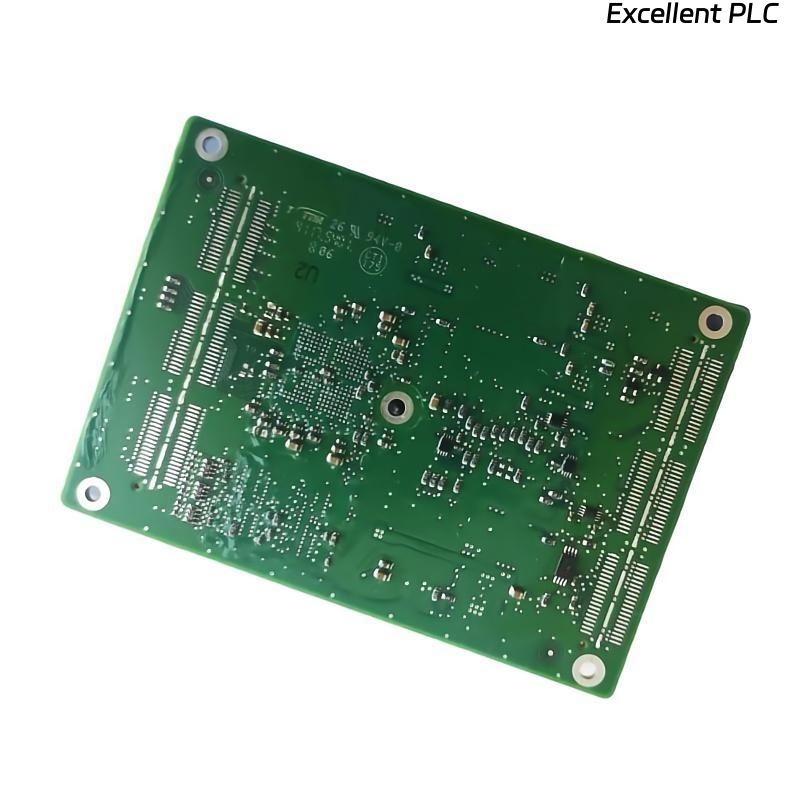

The ABB PPE091A101 3BHE044477P3 Controller Module is a high-performance industrial control component designed for demanding automation environments. It forms an integral part of ABB’s distributed control systems (DCS), ensuring reliable and precise control of complex industrial processes. This module supports real-time data processing and communication, enabling efficient system performance and operational stability.

The PPE091A101 module is engineered to operate in harsh industrial conditions, offering robustness and longevity. Its compatibility with various ABB control systems makes it an essential component for industries such as power generation, oil and gas, chemical manufacturing, and utilities. The module facilitates seamless integration with other automation hardware and software, providing flexibility in system design and upgrades.

Product Specifications

| Parameter | Details |

|---|---|

| Model Number | PPE091A101 / 3BHE044477P3 |

| Functionality | Controller Module for DCS |

| Power Supply | 24 V DC |

| Communication | Supports PROFIBUS, Modbus, Ethernet (depending on system integration) |

| Processing Unit | High-speed CPU optimized for control logic execution |

| Input/Output Interface | Supports multiple digital and analog I/O types |

| Operating Temperature | -20 °C to +70 °C |

| Storage Temperature | -40 °C to +85 °C |

| Humidity Range | 5% to 95% (non-condensing) |

| Dimensions (HxWxD) | 160 x 120 x 90 mm |

| Weight | 1.2 kg |

| Mounting | DIN rail / Panel mount |

| Compliance | CE, UL, IEC Standards |

Product Applications

The ABB PPE091A101 Controller Module is widely used in critical industrial automation applications where precise control and high reliability are required. Typical applications include:

-

Power Plant Control Systems: For turbine management, generator controls, and grid interface.

-

Oil & Gas Automation: Monitoring and control of drilling operations, pipeline management, and refinery processes.

-

Chemical and Petrochemical Plants: Control of reactors, distillation columns, and safety shutdown systems.

-

Water and Wastewater Treatment: Automated monitoring and process control of purification and distribution systems.

-

Manufacturing: Integration in automated production lines for process monitoring and control.

-

Utilities and Infrastructure: Supervisory control for HVAC, lighting, and building automation.

Product Advantages

The ABB PPE091A101 module offers several significant advantages that make it a preferred choice for industrial automation engineers:

-

High Reliability: Designed to withstand harsh industrial environments with wide temperature and humidity tolerance.

-

Real-Time Processing: Fast CPU architecture allows quick execution of complex control algorithms.

-

Flexibility: Compatible with various communication protocols and easy integration with ABB’s control ecosystem.

-

Scalability: Can be used in small standalone systems or large distributed control systems.

-

Robust Diagnostics: Built-in diagnostic features for quick troubleshooting and maintenance.

-

Energy Efficiency: Low power consumption contributes to overall system energy savings.

-

Modular Design: Simplifies system upgrades and maintenance without extensive downtime.

-

Safety Features: Supports fail-safe modes and emergency shutdown integration to enhance plant safety.

-

Long-Term Support: ABB’s global service network ensures availability of parts and technical assistance.

-

Compact Size: Facilitates easy installation even in space-constrained control panels.

Frequently Asked Questions (FAQ)

-

What communication protocols does the PPE091A101 support?

It supports multiple industrial protocols including PROFIBUS, Modbus, and Ethernet, depending on the system configuration. -

Can this controller module handle both analog and digital signals?

Yes, the module supports various digital and analog input/output interfaces for versatile control applications. -

What is the maximum operating temperature for the PPE091A101?

The module is rated for continuous operation between -20 °C and +70 °C. -

Is the controller module suitable for hazardous environments?

While robust, the PPE091A101 itself is not certified for hazardous locations; it must be installed within an approved enclosure. -

How does the module handle system failures or communication loss?

It includes built-in diagnostics and supports fail-safe operational modes to maintain safe process conditions. -

What type of CPU does the PPE091A101 use?

It uses a high-speed processor optimized for real-time control tasks, specific details can be found in ABB’s technical documentation. -

Can the PPE091A101 be used for safety-critical control applications?

Yes, when integrated properly, it supports safety-related functions and complies with applicable safety standards. -

What is the recommended power supply voltage range?

The module operates reliably on a 24 V DC power supply, with specified tolerance ranges detailed in the manual. -

How is firmware updated on the PPE091A101?

Firmware updates are performed via ABB’s proprietary software tools over supported communication interfaces. -

Does the controller support redundancy for high availability systems?

Yes, the PPE091A101 supports redundant configurations to ensure uninterrupted control during hardware failures.

Related Models from the Same Series

| Model Number | Description | Key Features |

|---|---|---|

| PPE091A102 | Controller Module with extended I/O | Increased input/output capacity |

| PPE091A103 | High-speed Controller Module | Enhanced CPU for faster processing |

| PPE091A104 | Safety-Integrated Controller | Includes safety logic functions |

| PPE091A105 | Redundant Controller Module | Supports dual redundant CPUs |

| PPE091A106 | Network-Optimized Controller | Enhanced network protocol support |

| PPE091A107 | Compact Controller Module | Smaller footprint for tight spaces |

Popular ABB Models from the Same Brand

| Model Number | Description | Typical Application |

|---|---|---|

| AC500 PLC | Programmable Logic Controller | General industrial automation |

| DCS800 Drive | Industrial Drive Controller | Motor and drive management |

| PCS100 Inverter | Power Converter | Renewable energy systems |

| RTU540 | Remote Terminal Unit | Remote monitoring and control |

| S800 I/O Modules | Distributed I/O Modules | Scalable input/output expansion |

| Freelance DCS | Distributed Control System | Integrated process automation |

Excellent PLC

Excellent PLC