| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

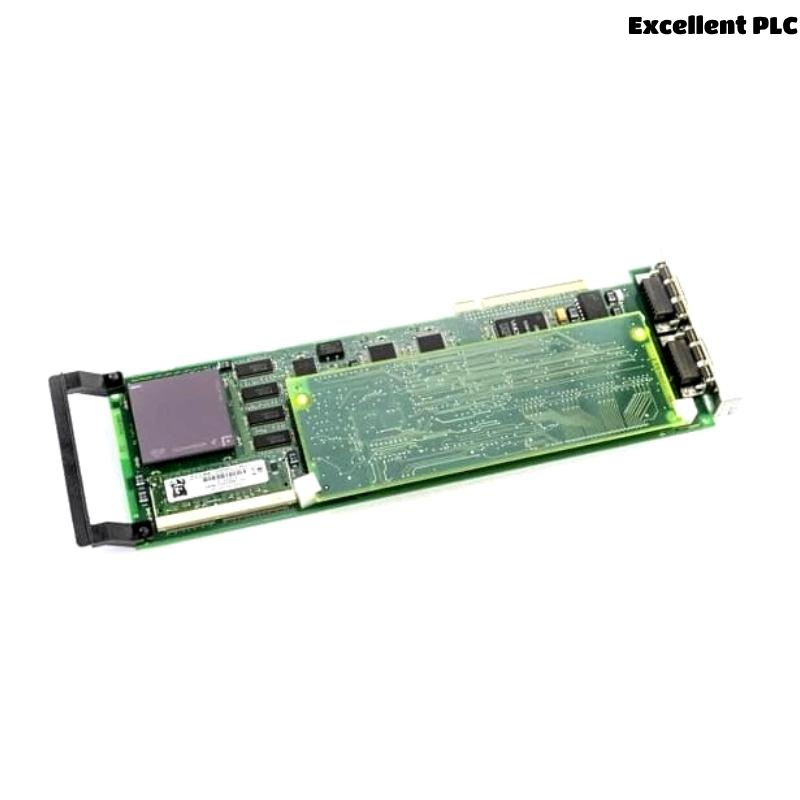

The ABB PU515 3BSE013063R1 is a high-performance Real-Time Accelerator Board engineered to meet the advanced demands of industrial automation systems within the ABB 800xA and AC 800M platforms. As a successor and enhancement to the earlier PU514 series, the PU515 introduces more powerful processing capabilities, faster communication, and improved system integration, all optimized for real-time deterministic control.

Designed specifically for complex applications that require sub-millisecond control response and reliable task scheduling, the PU515 plays a critical role in increasing execution speed for process control loops, logic evaluations, and communication handling. Its robust design makes it suitable for use in environments such as power generation, oil and gas processing, and large-scale manufacturing where precision and responsiveness are vital.

Technical Specifications

| Parameter | Specification |

|---|---|

| Product Name | Real-Time Accelerator Board |

| Model Number | PU515 |

| Product Code | 3BSE013063R1 |

| System Compatibility | ABB 800xA, ABB AC 800M |

| Processor Type | High-speed parallel processing unit |

| Memory Type | Embedded high-speed RAM and onboard cache |

| Interface | High-speed PCI-compatible connector |

| Power Supply | Supplied via backplane (5V DC) |

| Function | Accelerates execution of control tasks |

| Status Indicators | Integrated diagnostic and status LEDs |

| Cooling Method | Passive cooling with heat dissipation fins |

| Operating Temperature | 0°C to +60°C |

| Storage Temperature | -40°C to +85°C |

| Humidity | 5–95% RH, non-condensing |

| Certifications | CE, RoHS, UL, EMC-compliant |

| Dimensions (L × W × H) | 126 x 20 x 324 mm |

| Weight | 0.4 kg |

Applications

-

Power Plants (Thermal, Hydro, Nuclear): Enhances fast-response control for turbines, breakers, and load shedding systems.

-

Oil & Gas Refineries: Supports rapid event response in safety and emergency shutdown systems (ESD).

-

Pharmaceutical Manufacturing: Delivers precise control needed for validated batch processing and cleanroom automation.

-

Chemical Plants: Used in high-speed logic execution for continuous and batch processing applications.

-

Pulp & Paper Industry: Optimizes machine section control and drive systems with fast control loop processing.

-

Mining & Metallurgy: Handles rugged environmental demands while accelerating control logic for hoists and conveyors.

Product Advantages

-

Superior Real-Time Performance: Offers improved control loop responsiveness and precision timing compared to earlier models.

-

Next-Generation Hardware Architecture: Designed with higher computational power to support growing control system demands.

-

Plug-and-Play Integration: Fully compatible with existing ABB automation infrastructure (800xA and AC 800M).

-

Reduced System Latency: Enables rapid processing of I/O tasks and real-time computations for mission-critical operations.

-

Minimal Energy Consumption: Optimized design for low power usage while maintaining high performance.

-

Reliable Diagnostics: Built-in LED indicators and integration with ABB engineering tools for real-time status monitoring.

-

Industrial-Grade Durability: Rugged components and passive cooling make it ideal for 24/7 industrial operation.

Frequently Asked Questions (FAQ)

-

What is the primary function of the PU515 board?

The PU515 accelerates real-time processing and enhances performance in ABB control systems by offloading and speeding up critical control tasks. -

Is PU515 compatible with PU514 or PU514A?

Yes, PU515 is the next-generation upgrade, offering backward compatibility with previous PU514 series boards. -

Can I use PU515 in redundant systems?

Yes, PU515 supports use in both simplex and redundant control configurations. -

Does the PU515 require additional drivers or firmware?

ABB’s system engineering tools include support for PU515; firmware updates are provided as part of ABB lifecycle services. -

What types of control applications benefit most from PU515?

Applications with demanding response time requirements, such as ESD systems, high-speed control loops, and advanced batch control. -

How can I monitor the health of the PU515 board?

Through ABB’s Control Builder tools and onboard status LEDs that indicate operating state and errors. -

Is PU515 hot-swappable?

In most system configurations, yes, but always follow ABB’s recommended maintenance and replacement procedures. -

Does PU515 contribute to energy savings?

Yes, it is optimized for low power consumption while offering high performance. -

Is PU515 compliant with international industrial standards?

Yes, it holds CE, UL, and RoHS certifications and conforms to EMC guidelines. -

Can PU515 be used in hazardous industrial zones?

It can be used in industrial control cabinets in hazardous zones when paired with certified enclosures and system components.

Related or Same-Series ABB Models

| Model | Description | System Compatibility |

|---|---|---|

| PU514 3BSE013062R1 | Real-Time Accelerator Board (earlier model) | ABB 800xA / AC 800M |

| PU514A 3BSE032400R1 | Enhanced PU514 model with improved architecture | ABB AC 800M / 800xA |

| PM861AK01 | Processor Module for AC800M System | ABB AC 800M |

| PM864AK01 | Advanced CPU Module | ABB AC 800M / 800xA |

| TP830 | Baseplate for CPU and Communication Modules | AC800M Infrastructure |

| CI853K01 | PROFIBUS-DP Communication Interface Module | ABB Control Systems |

Popular ABB Modules Across Industries

| Model | Description | Common Applications |

|---|---|---|

| PM865 | High-Performance Redundant CPU Module | Power, Petrochemical |

| AI810 | 8-Channel Analog Input Module (4–20mA) | Process and Industrial Control |

| DO820 | 16-Channel Digital Output Module (24VDC) | Actuator and Device Control |

| DI810 | 16-Channel Digital Input Module | Signal Acquisition |

| CI854AK01 | Communication Interface for PROFIBUS Networks | Distributed Control Systems |

| PM891K01 | Flagship CPU Module for Complex Automation Scenarios | High-Availability Applications |

Excellent PLC

Excellent PLC