| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

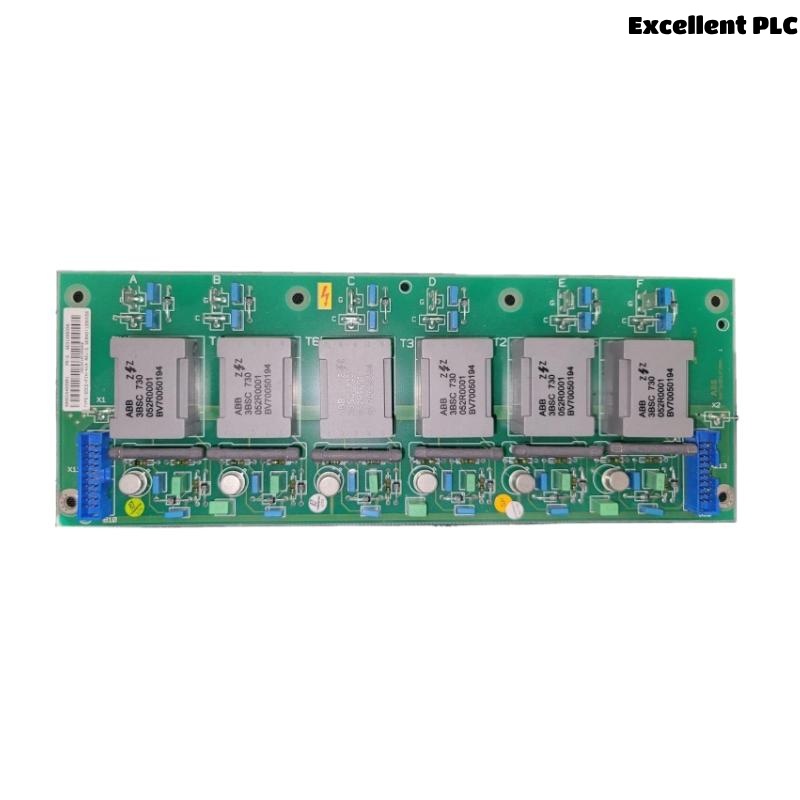

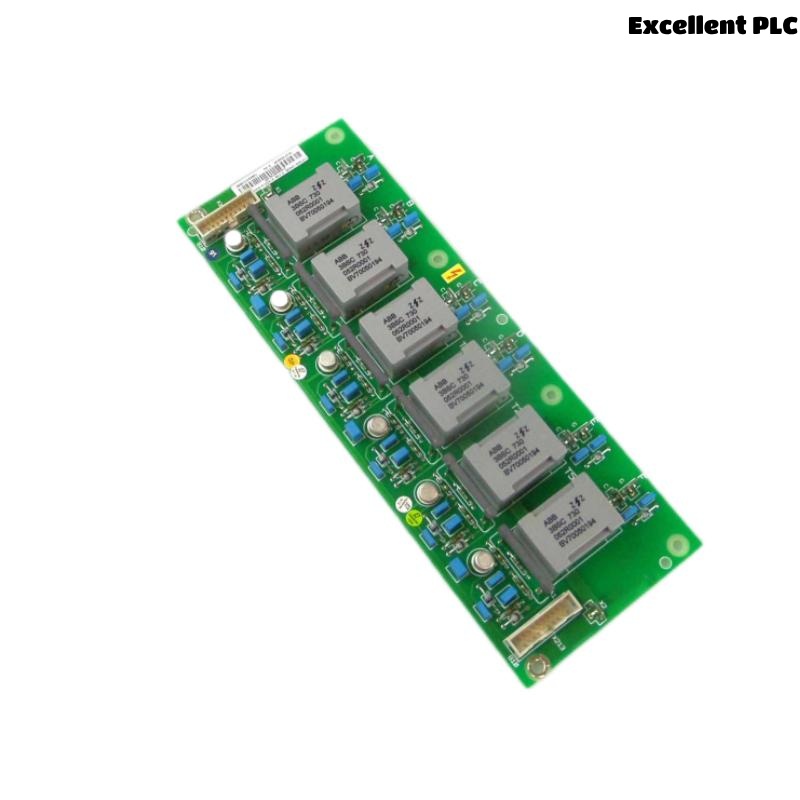

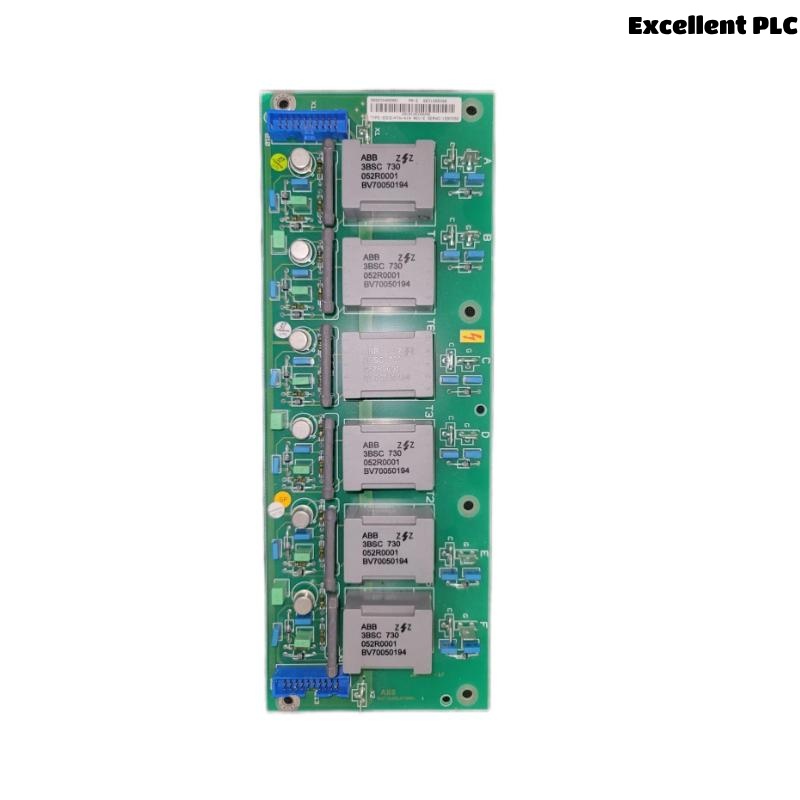

The ABB SDCS‑PIN‑41A 3BSE004939R1 is a next‑generation power interface board engineered for ABB’s high‑performance DC drive families—including the DCS400, DCS500 and DCS600 series. Acting as the electrical “nerve centre” between the control electronics and the power stack, the board distributes DC bus energy, conditions feedback signals, and safeguards the drive against abnormal power events.

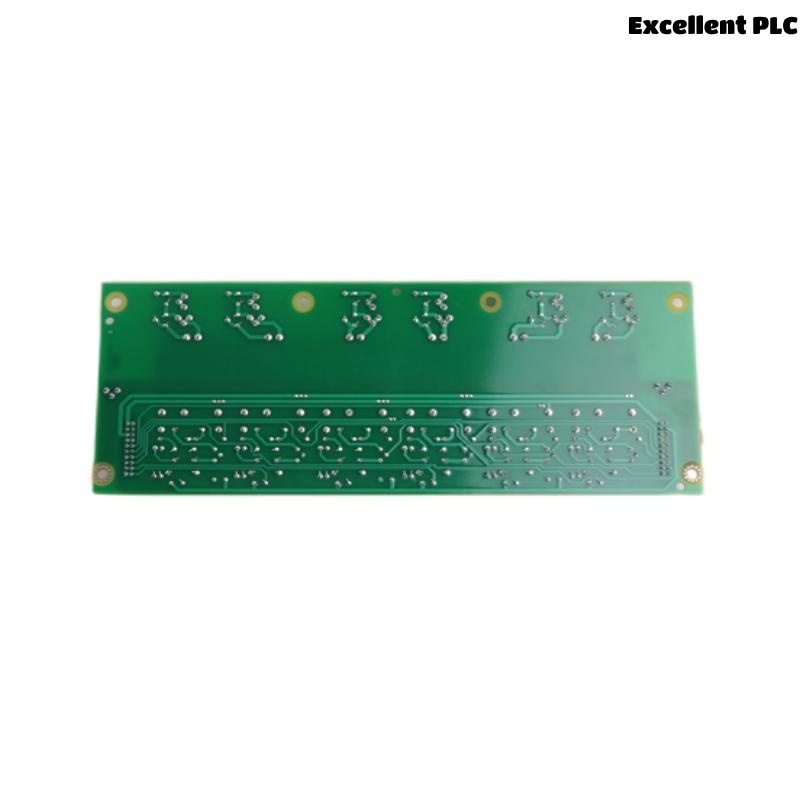

Built on a multilayer industrial PCB with reinforced copper paths, the SDCS‑PIN‑41A delivers low‑impedance current routing, excellent thermal stability, and long service life. A compact mechanical footprint allows easy retrofits in tight cubicles, while plug‑and‑play connectors speed up installation and cut commissioning time.

Product Specifications

| Parameter | Specification |

|---|---|

| Dimensions | 265 × 282 × 40 mm |

| Weight | 0.56 kg |

| Operating Voltage (DC bus) | up to 600 VDC |

| Control Supply | 24 VDC (typical) |

| Compatible Drives | DCS400 / DCS500 / DCS600 |

| PCB Construction | 6‑layer FR‑4, 70 µm copper |

| Connectors | Plug‑in spring terminals & ribbon headers |

| Cooling Method | Forced‑air (via drive ventilation path) |

| Operating Temperature | 0 °C … +55 °C |

| Storage Temperature | –25 °C … +70 °C |

| Humidity Range | 5 % … 95 % non‑condensing |

| Vibration Compliance | IEC 60068‑2‑6 |

| Insulation Category | IEC 60664‑1, Over‑voltage Cat III |

| Approvals / Compliance | CE, RoHS, ISO 9001 |

Product Applications

-

Steel & Aluminium Mills – Precise armature current control for rolling stands, coilers and annealing lines.

-

Pulp & Paper Plants – Stable power interface for DC‑driven paper machines, winders and cutters.

-

Mining Conveyors & Hoists – Robust performance in dusty, high‑shock environments requiring high torque.

-

Marine Propulsion & Cranes – Smooth torque delivery and regenerative braking for winches and thrusters.

-

Material Handling Systems – Reliability for stacker‑reclaimers, sorters, and automated warehouses.

-

Test Benches & Labs – Accurate power distribution for motor‑performance test stands and R&D rigs.

Product Advantages

-

High Current Capacity – Wide copper tracks and generous creepage distances handle heavy DC loads with minimal loss.

-

Rapid Field Replacement – Tool‑free connectors allow swap‑out in minutes, trimming costly downtime.

-

Noise Immunity – Layer stack‑up and ground planes reduce EMC susceptibility, ensuring clean feedback signals.

-

Compact & Lightweight – Only 265 × 282 × 40 mm and 0.56 kg, lowering enclosure space and shipping cost.

-

Integrated Protection – On‑board snubbers and surge paths shield IGBTs and thyristors from transients.

-

Extended Service Life – Industrial‑grade capacitors and conformal coating resist humidity and chemical attack.

-

Global Standards – CE and RoHS compliance eases acceptance in international projects.

-

Thermal Efficiency – Optimised copper and ventilation holes maintain uniform temperature distribution.

-

Diagnostic Friendly – Clear test points and silkscreen legends accelerate troubleshooting.

-

ABB Ecosystem Fit – 100 % firmware and mechanical compatibility with legacy ABB DC drive frames.

Frequently Asked Questions (FAQ)

-

What role does the SDCS‑PIN‑41A play in a DC drive?

It routes DC bus power, conditions feedback, and provides protective interfaces between the control PCB and power semiconductors. -

Is the board interchangeable with earlier SDCS‑PIN versions?

Yes—mechanical size and connectors match earlier PIN boards, enabling drop‑in replacement. -

Can the board operate above 600 VDC?

No. Exceeding 600 VDC risks insulation breakdown; use the specified voltage range. -

Does the board need separate cooling?

It relies on the host drive’s fan airflow; no dedicated heatsink is required. -

How do I verify correct installation?

Check that ribbon cables are fully latched and all spring terminals are firmly seated; perform a low‑voltage power‑up test. -

What maintenance is recommended?

Annual visual inspection for dust, loose connectors and discoloration; clean gently with dry compressed air. -

Is firmware flashing required after replacement?

No firmware resides on the PIN board; system firmware stays in the control board. -

Can I operate the drive in high humidity coastal plants?

Yes—the board is conformally coated; keep humidity non‑condensing and ensure cabinet IP rating. -

What happens if a DC bus surge occurs?

On‑board protection clamps the surge; any severe event is reported via the drive’s fault codes. -

Where can spare parts be sourced?

Through ABB’s global spare‑parts program or authorised distributors, ensuring genuine components and warranty.

Related Models (Same Series or Function)

| Model | Description |

|---|---|

| SDCS‑PIN‑40 | Predecessor board for early DCS400 frames. |

| SDCS‑PIN‑41 | Standard interface board with basic protection. |

| SDCS‑PIN‑42 | Variant with extended temperature rating. |

| SDCS‑PIN‑43 | Board featuring additional snubber circuitry. |

| SDCS‑POW‑1 | Dedicated power supply board for auxiliary voltages. |

| SDCS‑CON‑1 | Signal conditioning board complementary to PIN series. |

Popular ABB Models (Same Brand)

| Model | Applications |

|---|---|

| SDCS-PIN-52 | Digital I/O module, Control systems |

| SDCS-PIN-F01 | Signal processing, Industrial automation |

| SDCS-PIN-F01a | Field I/O interface, Data acquisition |

| SDCS-PIN-53 | Machine control, Process monitoring |

| SDCS-PIN-F02 | Safety control, Equipment diagnostics |

| SDCS-PIN-F03 | High-speed data transmission, Remote control |

Excellent PLC

Excellent PLC