| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

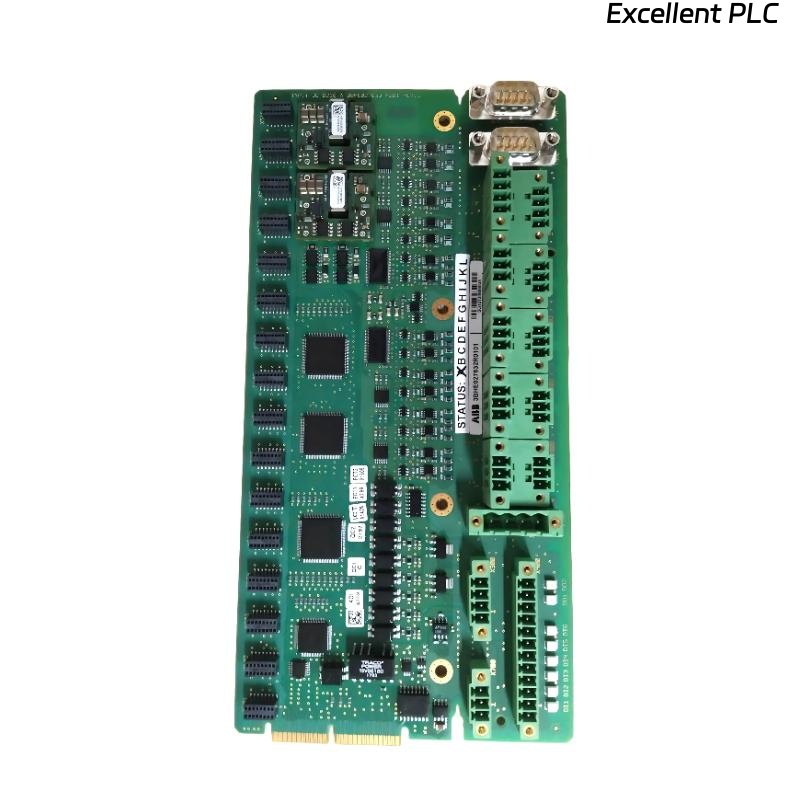

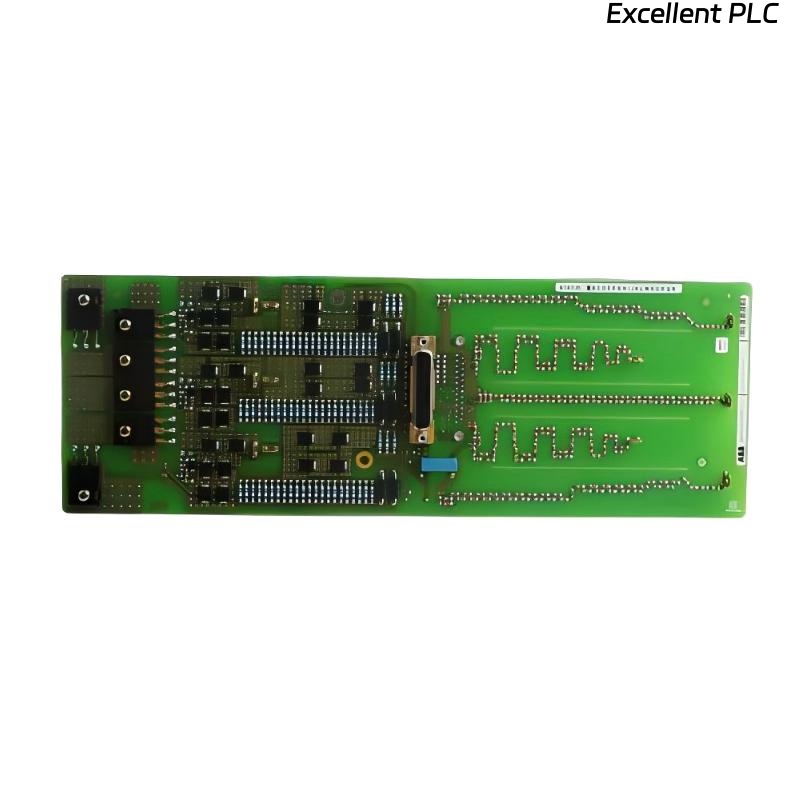

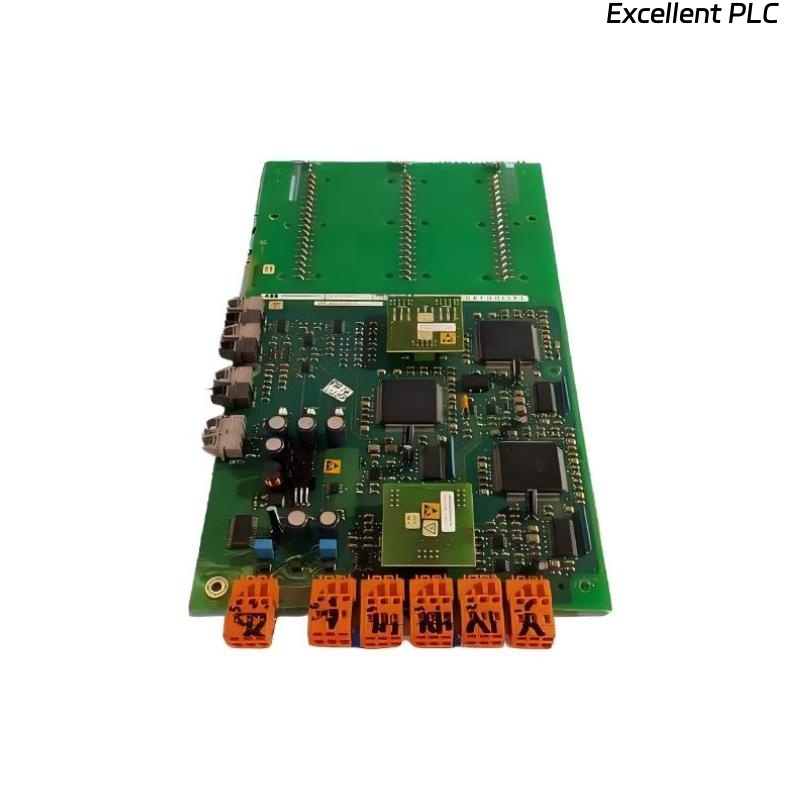

The ABB TB826 3BSE061637R1 is an industrial I/O terminal board used primarily in ABB’s Symphony Plus and Advant Master Distributed Control Systems (DCS). This terminal unit serves as a vital interface between field instrumentation and the control system, facilitating secure and efficient signal termination. ABB designed the TB826 with precision, offering reliable connections for analog or digital I/O modules, ensuring dependable plant automation in diverse industrial environments.

With robust construction, compliance with industrial standards, and ease of installation, the TB826 stands as a critical component in the integration of automation solutions across various process industries. Its high-density connection capabilities and mechanical durability make it a preferred choice among engineers for both new installations and retrofit projects.

Product Features and Advantages

-

Robust Design: Constructed using high-quality materials to withstand industrial stress, vibration, and temperature fluctuations.

-

Efficient Signal Management: Supports clear and organized wiring for input/output signals, reducing complexity in the field wiring layout.

-

Easy Mounting: DIN-rail mountable and equipped with clear terminal labeling, ensuring a streamlined installation process.

-

Compact Footprint: Space-saving design optimized for dense cabinet configurations in industrial automation systems.

-

Long-Term Reliability: ABB’s engineering excellence ensures consistent performance over extended operating periods with minimal maintenance.

-

System Compatibility: Seamlessly integrates with various ABB controller families, including AC800M, S800 I/O, and Symphony Plus.

-

Reduced Downtime: Simplified maintenance and diagnostic access allow quick troubleshooting and minimal system disruption.

Technical Specifications

| Parameter | Specification |

|---|---|

| Model Number | TB826 |

| ABB Part Number | 3BSE061637R1 |

| Type | Terminal Base / I/O Termination Unit |

| Compatible Systems | Symphony Plus, Advant Master, AC800M, S800 I/O |

| Mounting Type | DIN-rail |

| Connection Type | Screw terminals |

| Number of Channels | Typically supports 8, 16, or 32-channel I/O modules |

| Electrical Isolation | Yes (channel-to-channel and channel-to-ground) |

| Max Voltage | 30 VDC |

| Operating Temperature | -20°C to +70°C |

| Storage Temperature | -40°C to +85°C |

| Relative Humidity | 5% to 95% non-condensing |

| Dimensions | 85.6 x 136 x 58.5 mm |

| Weight | 0.21 kg |

| Protection Rating | IP20 (when mounted in control cabinet) |

| Material | Industrial-grade thermoplastic |

| Approvals/Certifications | CE, RoHS, IEC compliant |

Application Areas

The ABB TB826 is widely applied across multiple industrial domains where signal integrity and system reliability are critical:

-

Power Generation – Turbine control, boiler automation, and balance-of-plant systems.

-

Chemical & Petrochemical Plants – Interface for analog transmitters, thermocouples, and RTDs.

-

Water and Wastewater Treatment – Ensures accurate data acquisition from remote sensors and actuators.

-

Oil & Gas – Facilitates upstream and downstream process control.

-

Pharmaceutical Manufacturing – Secure and validated wiring interface for automation systems.

-

Pulp and Paper – Integration of process and machine-level I/Os into the DCS.

-

Metals and Mining – Facilitates automation of processing and safety systems.

Frequently Asked Questions (FAQ)

1. What is the main function of the ABB TB826?

The TB826 serves as a termination base for I/O modules, enabling secure electrical connection between field devices and ABB’s automation controllers.

2. Is the TB826 compatible with the AC800M controller?

Yes, the TB826 is fully compatible with ABB’s AC800M controllers and other S800 I/O modules.

3. Can the TB826 be used in harsh environments?

While the TB826 itself has an IP20 rating, when installed inside a protected control cabinet, it can operate in demanding industrial conditions.

4. How is the TB826 mounted?

It is designed for DIN-rail mounting, simplifying installation in standard control cabinets.

5. What type of connections does the TB826 support?

It uses screw terminal connections for robust and vibration-resistant wiring.

6. Is the TB826 hot-swappable?

No, the TB826 itself is not hot-swappable. However, some I/O modules connected to it may support hot-swapping depending on the system.

7. What are the dimensions of the TB826?

Its dimensions are approximately 120 mm (W) x 80 mm (H) x 60 mm (D).

8. How many I/O channels can the TB826 support?

This depends on the I/O module being used, but typically it supports modules with 8 to 32 channels.

9. Is this terminal base pre-wired?

No, it requires manual wiring during installation, but the terminals are clearly labeled for ease of use.

10. Is the TB826 certified for industrial applications?

Yes, it meets CE, RoHS, and IEC standards, ensuring compliance for global installations.

6 Related or Compatible Models

| Model Number | Description | Compatibility | Key Features |

|---|---|---|---|

| TB810 | Compact terminal base for analog signals | AC800M, S800 I/O | Cost-effective, small footprint |

| TB820 | Extended terminal base | Symphony Plus, Advant | Additional channel support |

| TU810V1 | Analog I/O terminal unit | S800 I/O | Enhanced field wiring connections |

| TU830V1 | 16-channel terminal unit | S800 I/O | With fusing options |

| TU842 | Extended terminal unit with diagnostics | S800 I/O | Diagnostics support, DIN rail mount |

| TB840A | Redundant terminal base | Redundant I/O systems | Dual connections for high availability |

6 Popular ABB Models (Same Brand)

| Model Number | Description | Application Area | Key Feature |

|---|---|---|---|

| AC800M | High-performance process controller | Process automation | Modular, IEC 61131-3 compliant |

| PM864AK01 | CPU unit for AC800M system | Distributed control systems | Ethernet support, compact design |

| CI854AK01 | Communication interface for Profibus DP | Industrial networks | Dual-channel Profibus interface |

| TU849 | Redundant terminal unit | Critical infrastructure | Dual-channel redundancy |

| AI810 | Analog input module (8 channels) | Process inputs | High accuracy signal processing |

| DO820 | Digital output module | Discrete control | Fast switching outputs |

Excellent PLC

Excellent PLC