| Company Information | ||||||||

| sales@xmjzjsgs.com | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

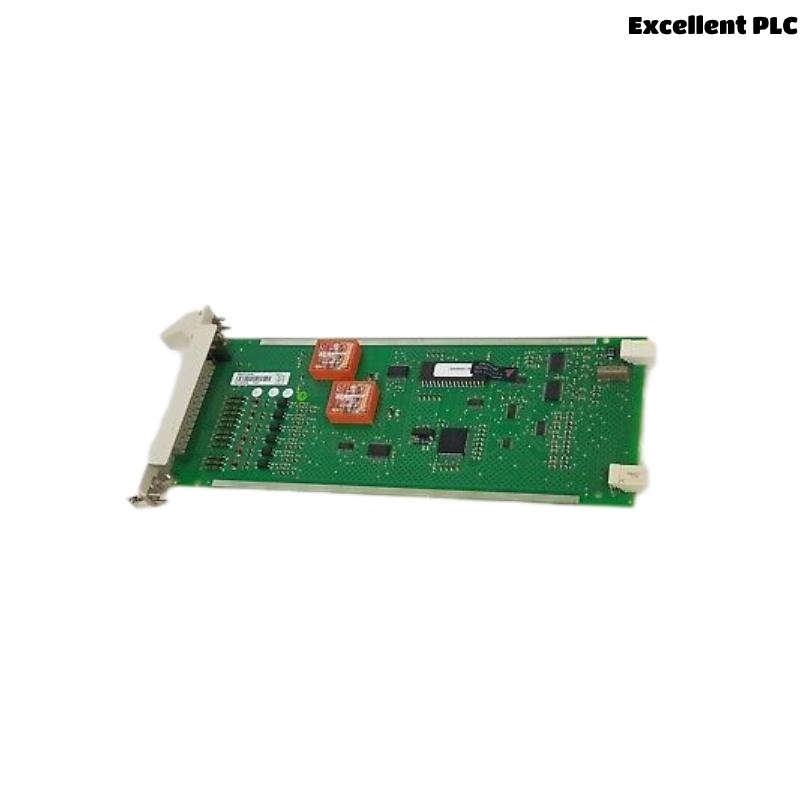

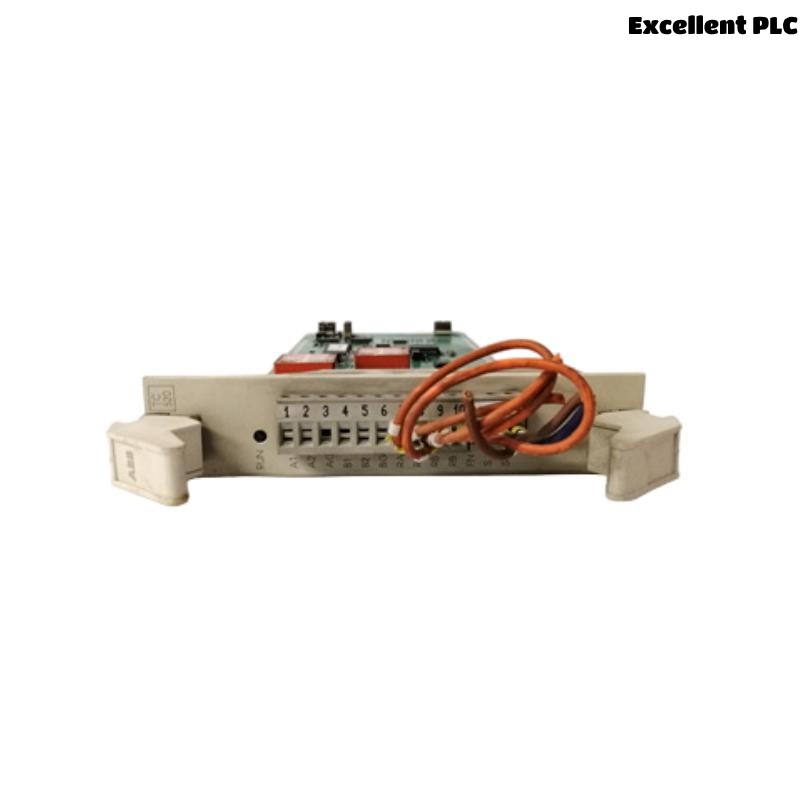

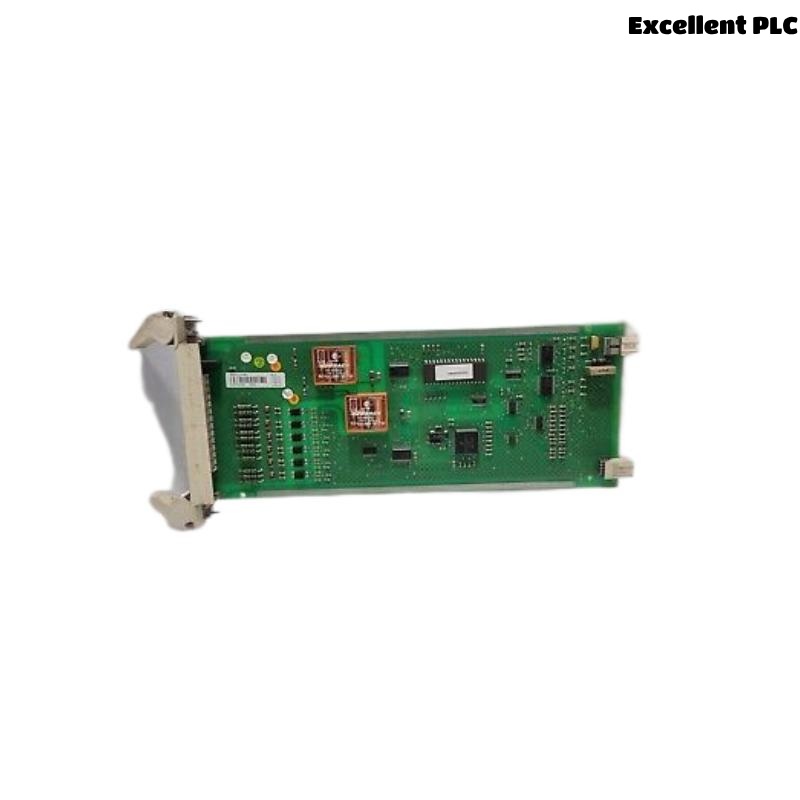

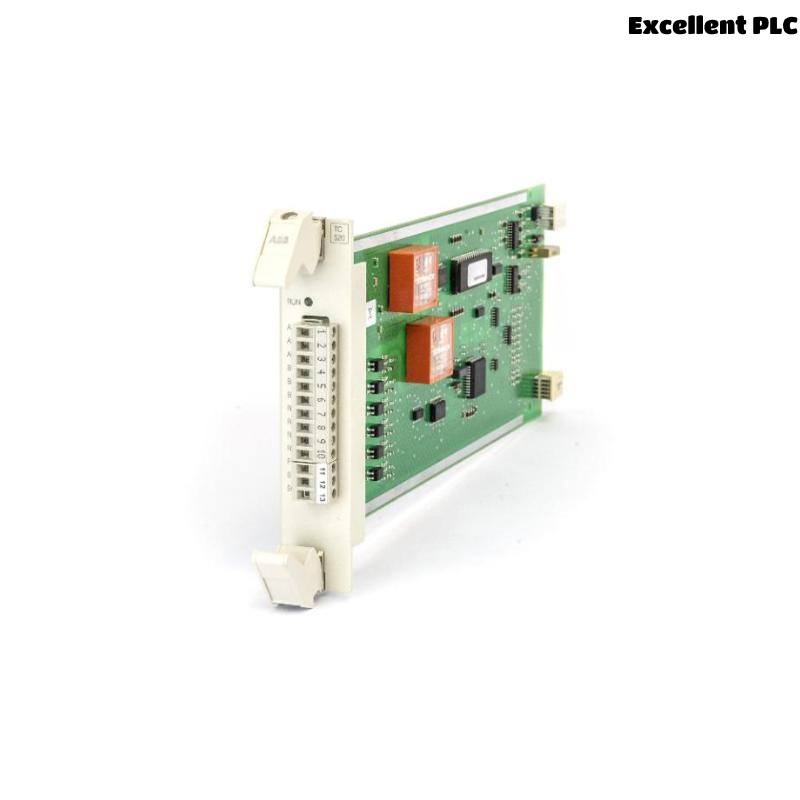

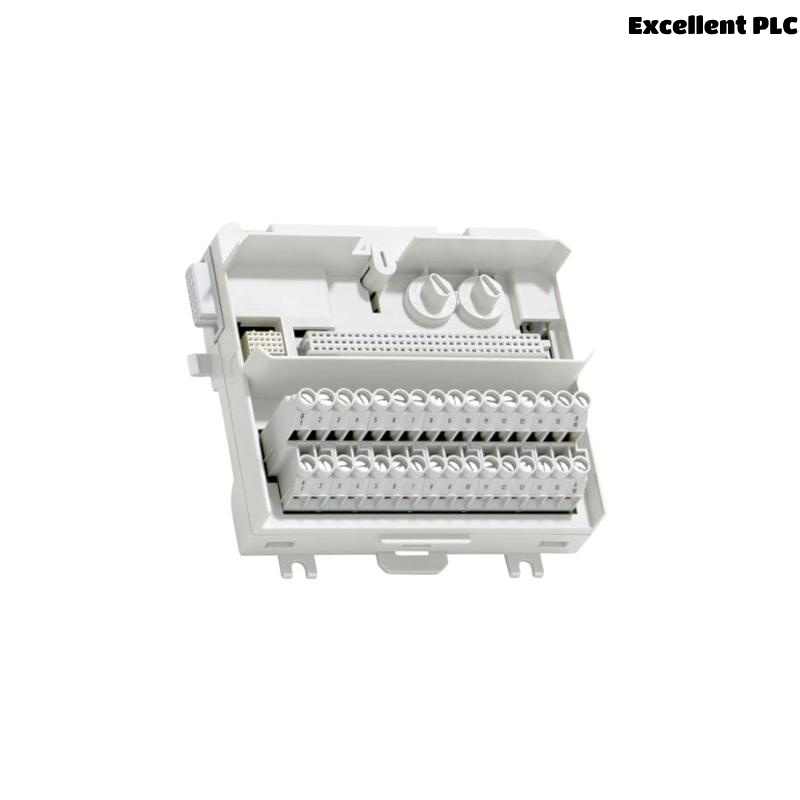

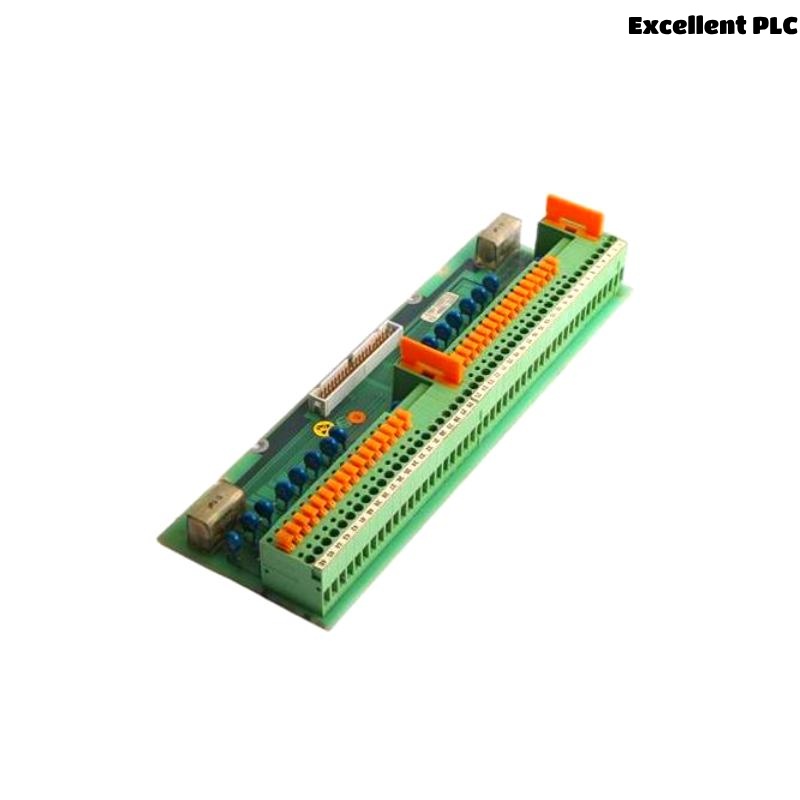

The ABB TC520 System Status Collector (Ordering Code: 3BSE001449R1) is a specialized data acquisition and monitoring device designed to aggregate and collect status information from various industrial control system components. Developed by ABB, the TC520 plays a critical role in system diagnostics, performance tracking, and fault detection across distributed control systems (DCS).

Its robust construction and versatile communication capabilities enable it to operate efficiently within demanding industrial environments, including power plants, chemical processing, and manufacturing facilities. The device supports seamless integration with ABB’s 800xA automation platform and other control architectures, providing real-time visibility into system status and enhancing operational reliability.

With a compact form factor and lightweight design, the TC520 facilitates straightforward installation in control cabinets, minimizing space requirements while maximizing functionality.

Product Parameters

| Parameter | Specification |

|---|---|

| Model | TC520 |

| Ordering Code | 3BSE001449R1 |

| Function | System Status Collector |

| Input Interfaces | Digital and analog inputs support |

| Communication | PROFIBUS, Modbus, Ethernet (optional) |

| Data Acquisition | Real-time system status monitoring |

| Power Supply | 24 V DC |

| Operating Temperature | -20°C to +60°C |

| Storage Temperature | -40°C to +85°C |

| Mounting | DIN Rail or Panel Mounting |

| Dimensions (L×W×H) | 279 x 27 x 153 mm |

| Weight | 0.29 kg |

| Housing Material | Robust plastic enclosure |

| Indicators | LED status indicators for power and communication |

| Certifications | CE, UL |

Product Applications

The ABB TC520 system status collector is widely utilized in a variety of industrial applications where monitoring the health and operational status of complex automation systems is critical. Typical applications include:

-

Distributed Control Systems (DCS): Collects and consolidates status data from multiple control modules to support diagnostic and performance analysis

-

Power Generation Plants: Monitors equipment status to ensure smooth and safe operation of turbines, generators, and auxiliary systems

-

Chemical and Petrochemical Facilities: Enables real-time monitoring of safety and process control systems to prevent malfunctions

-

Manufacturing Automation: Tracks operational states of machines and control devices to minimize downtime and optimize maintenance schedules

-

Water and Wastewater Treatment Plants: Provides continuous system health monitoring to maintain regulatory compliance and operational efficiency

-

Building Management Systems (BMS): Aggregates data from HVAC, lighting, and security control units for centralized management

-

Oil & Gas Industry: Facilitates status monitoring in pipeline control and refinery automation systems

-

Remote Monitoring Installations: Supports data collection in geographically dispersed control points for centralized analysis

Product Advantages

-

Comprehensive Status Collection: Supports a wide range of input signals, allowing integration with various control system components

-

Real-Time Monitoring: Provides instantaneous system status updates to enhance operational decision-making

-

Compact and Lightweight: Dimensions of 279 x 27 x 153 mm and a weight of just 0.29 kg allow flexible installation in constrained spaces

-

Flexible Mounting Options: DIN rail or panel mounting capabilities simplify integration into existing infrastructure

-

Multiple Communication Protocols: Supports PROFIBUS, Modbus, and optionally Ethernet, enabling easy network integration

-

Robust Build Quality: Durable plastic enclosure protects internal components from environmental stresses

-

Clear Status Indication: LED indicators facilitate quick diagnostics on power and communication states

-

Wide Operating Temperature Range: Suitable for varied industrial environments (-20°C to +60°C)

-

Low Power Consumption: Efficient operation reduces the need for extensive cooling or power infrastructure

-

Certified for Safety and Quality: CE and UL certifications guarantee compliance with international standards

Frequently Asked Questions (FAQ)

-

What is the primary function of the ABB TC520?

It acts as a system status collector, aggregating data from control system components for monitoring and diagnostics. -

What are the dimensions and weight of the TC520?

The device measures 279 x 27 x 153 mm and weighs 0.29 kg. -

Which communication protocols does the TC520 support?

It supports PROFIBUS, Modbus, and optionally Ethernet communication. -

Can the TC520 be mounted on a DIN rail?

Yes, it supports both DIN rail and panel mounting. -

What is the operating temperature range of the TC520?

The device operates safely within -20°C to +60°C. -

What kind of inputs does the TC520 accept?

It supports both digital and analog input signals. -

Is the TC520 compatible with ABB’s 800xA system?

Yes, it is designed to integrate seamlessly with ABB 800xA automation platforms. -

Does the TC520 have status indicators?

Yes, it features LED indicators for power and communication status. -

What power supply does the TC520 require?

It requires a 24 V DC power supply. -

Is the TC520 certified for industrial use?

Yes, it holds CE and UL certifications.

Recommended Related Models

| Model | Description | Function | Dimensions (mm) |

|---|---|---|---|

| TC510 | Basic system status collector | Status data aggregation | 250 x 25 x 140 |

| TC530 | Advanced system status collector | Enhanced diagnostics | 300 x 30 x 160 |

| TC540 | Status collector with Ethernet | Network-enabled data collection | 280 x 28 x 150 |

| TC550 | Multi-protocol status collector | Supports PROFIBUS & Modbus | 310 x 35 x 165 |

| TC560 | Wireless status collector | Remote system monitoring | 290 x 27 x 155 |

| TC570 | High-density status collector | Large-scale data acquisition | 320 x 40 x 170 |

Popular ABB Models

| Model | Description | Module Type | Application |

|---|---|---|---|

| PM865 | Processor module for automation | CPU Module | ABB 800xA control systems |

| CI854B | PROFIBUS communication interface | Communication Module | Fieldbus communication |

| DI831 | Digital input module | Digital Input | Signal processing |

| AO811V2 | Analog output module | Analog Output | Industrial control |

| TU840 | Terminal unit base for I/O modules | Base/Terminal Unit | Modular I/O systems |

| AI820 | Analog input module | Analog Input | Sensor signal acquisition |

Excellent PLC

Excellent PLC