| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

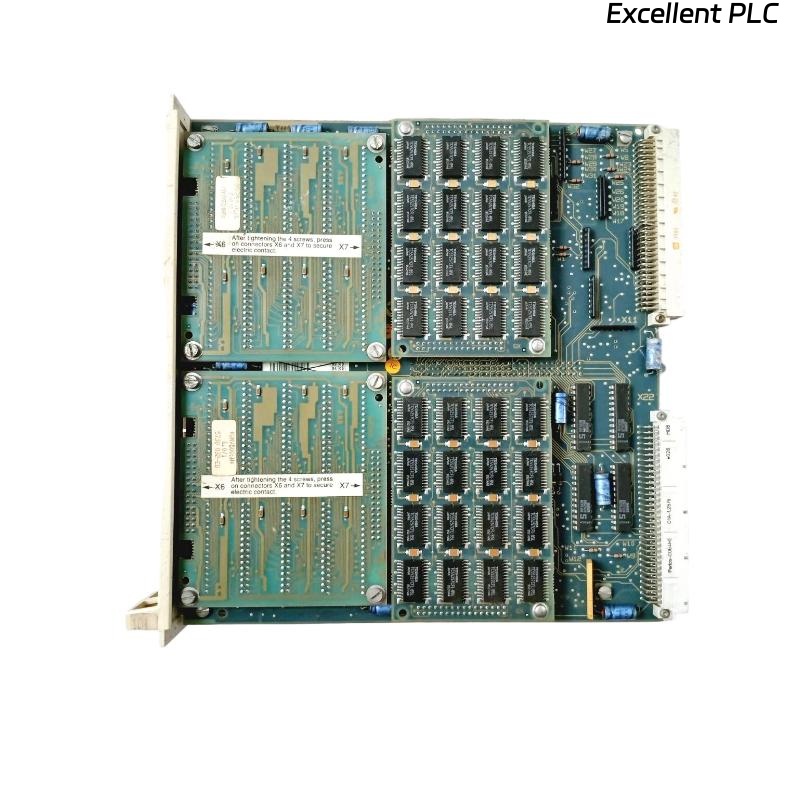

The ABB TP830 3BSE018114R1 Baseplate is a robust and precision-engineered mounting component designed for use within ABB’s modular automation and control systems, especially in the 800xA and AC 800M series. This baseplate serves as a reliable physical foundation for securing modules such as controllers, communication units, and I/O devices within a control rack or panel.

Manufactured with high-quality materials, the TP830 baseplate provides excellent mechanical support, ensuring stable alignment and minimizing vibrations that could compromise module connectivity or performance. Its standardized design allows for straightforward installation, maintenance, and scalability within industrial automation environments.

Product Specifications

| Parameter | Description |

|---|---|

| Product Name | TP830 Baseplate |

| Part Number | 3BSE018114R1 |

| Function | Mounting baseplate for ABB modular control and automation modules |

| Material | High-strength steel with corrosion-resistant coating |

| Surface Finish | Powder coated for durability and environmental resistance |

| Compatibility | ABB AC 800M, 800xA, S800 I/O modules |

| Mounting Type | Rack or panel mounting with screw fixing |

| Dimensions (W×H×D) | 200 x 100 x 30 mm |

| Weight | 1.2 kg |

| Operating Temperature | –20°C to +60°C |

| Protection Class | IP20 |

| Certifications | CE, RoHS compliant |

Product Applications

The ABB TP830 Baseplate is widely used in various industrial sectors, providing a secure platform for modular components. Typical application scenarios include:

-

Distributed Control Systems (DCS)

Serves as a mounting foundation for controllers and I/O modules in large-scale automation setups. -

Process Industries

Utilized in chemical, petrochemical, and power generation plants for stable module installation. -

Factory Automation

Supports PLC and I/O device mounting in assembly lines and manufacturing plants. -

Substation and Grid Automation

Provides reliable mechanical support for modules in control panels of electrical substations. -

Oil & Gas Facilities

Durable baseplate suitable for rugged environments where equipment stability is critical.

Product Advantages

-

Robust Mechanical Stability

Crafted from high-strength steel, the baseplate withstands industrial vibrations and physical shocks. -

Corrosion Resistance

Powder-coated surface protects against rust and environmental degradation. -

Standardized Dimensions

Compatible with a wide range of ABB modules, simplifying system integration. -

Easy Installation

Designed for quick mounting with pre-drilled holes and compatible fixing hardware. -

Lightweight Yet Durable

Offers the perfect balance between strength and weight to reduce rack load. -

Ensures Proper Alignment

Maintains module positioning for optimal electrical connections and cooling. -

Versatile Usage

Can be used in control rooms, panels, and field cabinets. -

Cost-Effective Solution

Reduces downtime by providing a stable platform minimizing module replacement or repair frequency. -

Compliance with Standards

Meets CE and RoHS directives, assuring safety and environmental friendliness. -

Long Service Life

Designed to last through multiple equipment lifecycle renewals in demanding industrial settings.

Frequently Asked Questions (FAQ)

-

What is the primary role of the ABB TP830 baseplate in control systems?

The TP830 baseplate acts as a foundational mounting platform designed to securely hold and align various ABB automation modules, ensuring mechanical stability and optimal connectivity within control racks or panels. -

Is the TP830 baseplate compatible with all ABB automation modules or only specific ones?

It is primarily designed for ABB AC 800M, 800xA, and S800 I/O series modules. While it may physically fit some other ABB modules, it is recommended to verify compatibility based on module dimensions and mounting specifications. -

What materials and surface treatments are used to enhance the baseplate’s durability?

The baseplate is manufactured from high-strength steel and features a powder-coated surface that provides excellent corrosion resistance and protects against industrial environmental factors such as humidity and dust. -

Can the baseplate support modules in harsh industrial environments, such as chemical plants or outdoor installations?

The baseplate’s IP20 rating means it offers limited protection against solid objects but no protection against water ingress. Therefore, it should be installed inside adequately sealed control cabinets or enclosures when used in harsh environments. -

What is the procedure for installing modules onto the TP830 baseplate? Are any special tools required?

Modules are mounted onto the baseplate using standard screws through pre-drilled holes. Installation does not require specialized tools—commonly, a screwdriver and appropriate screws are sufficient. Care should be taken to align modules correctly to avoid mechanical stress. -

How does the baseplate contribute to the overall reliability of the automation system?

By providing a rigid and vibration-resistant mounting surface, the baseplate reduces mechanical stress on connectors and wiring, minimizing the risk of intermittent contacts or damage that could lead to system downtime. -

What are the weight and size limitations of modules that can be safely mounted on the TP830 baseplate?

While the baseplate itself weighs 1.2 kg and measures 200 x 100 x 30 mm, it is engineered to support typical ABB modules within the AC 800M and 800xA range, which generally do not exceed a few kilograms each. For unusually heavy modules, additional mechanical support might be necessary. -

Are there any specific maintenance requirements for the baseplate after installation?

Routine inspection for signs of corrosion or physical damage is recommended, especially in corrosive environments. Cleaning should be done with a dry or slightly damp cloth, avoiding harsh chemicals that could damage the coating. -

Can the baseplate be retrofitted or upgraded in existing ABB control panels?

Yes, the TP830 baseplate is designed with standard dimensions and mounting points to facilitate easy retrofit or upgrade within existing systems, making system expansion or maintenance more efficient. -

Is the TP830 baseplate compliant with international standards for electrical and mechanical safety?

Yes, it meets CE marking requirements and RoHS directives, ensuring it complies with essential safety, health, and environmental protection standards applicable within the European Union and other regions following these standards.

Related Models (Same Series or Functionally Related)

| Model | Function | Compatibility | Notes |

|---|---|---|---|

| TP820 | Baseplate for smaller modules | AC 800M / 800xA | Compact size for space-limited panels |

| TP831 | Baseplate with enhanced cooling | AC 800M | Integrated heat dissipation design |

| TK566 | Interconnector | AC 800M / 800xA | Connects modular units physically |

| TB810 | ModuleBus terminator | AC 800M | Ends communication bus in modules |

| TU830V1 | Terminal base for DIN mounting | S800 I/O | Suitable for field wiring and terminals |

| CI860 | Communication Interface | AC 800M | Connects I/O clusters to controllers |

Popular ABB Models (Same Brand)

| Model | Function | System | Highlights |

|---|---|---|---|

| PM864AK01 | Controller Module | AC 800M / 800xA | High-performance CPU with redundancy support |

| DI810 | Digital Input Module | 800xA | 16-channel 24VDC input |

| DO810 | Digital Output Module | 800xA | 16-channel relay or transistor outputs |

| AI810 | Analog Input Module | 800xA | 8-channel analog signals, 4-20 mA |

| AO810V2 | Analog Output Module | 800xA | 8-channel analog output with diagnostics |

| CI854AK01 | PROFIBUS Interface Module | 800xA | Supports DP Master and Slave configurations |

Excellent PLC

Excellent PLC