| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

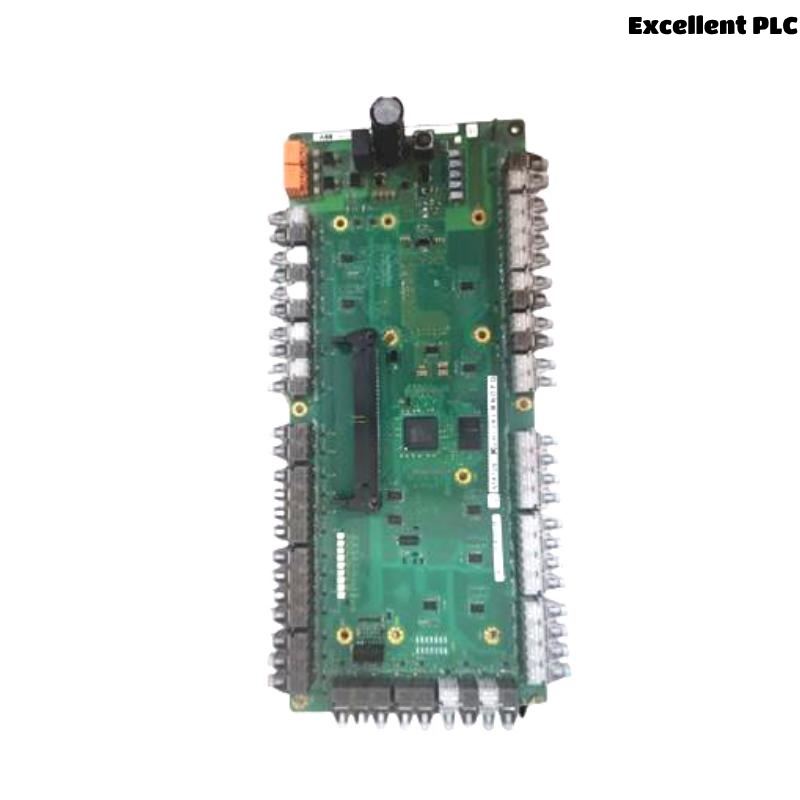

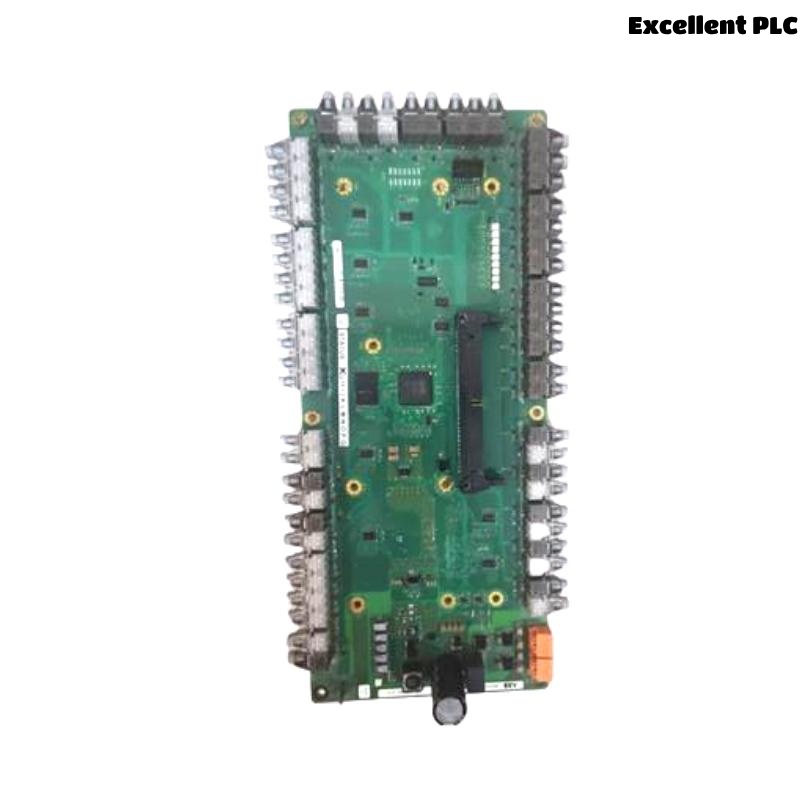

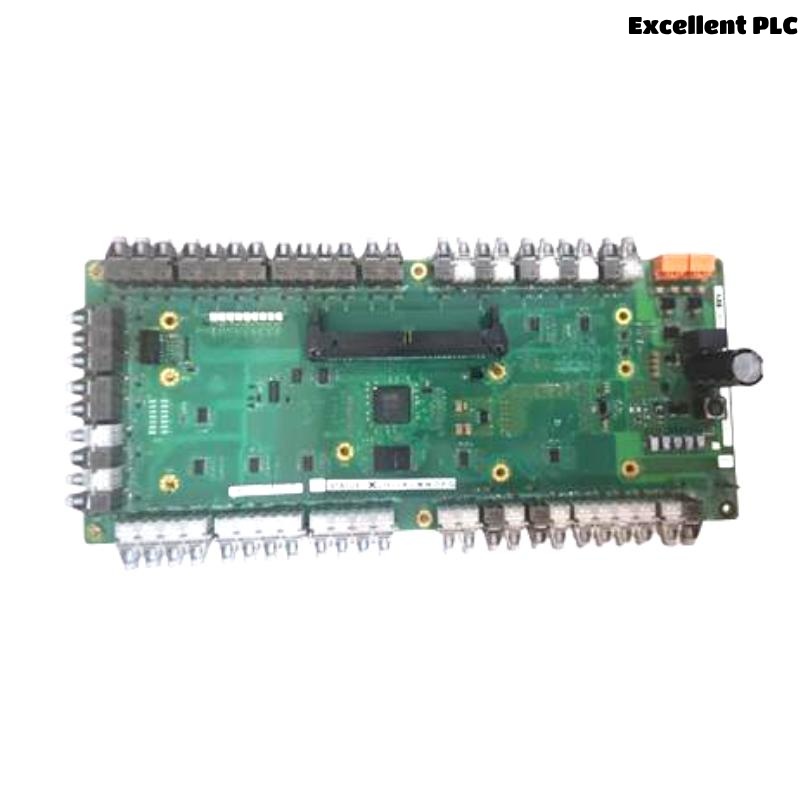

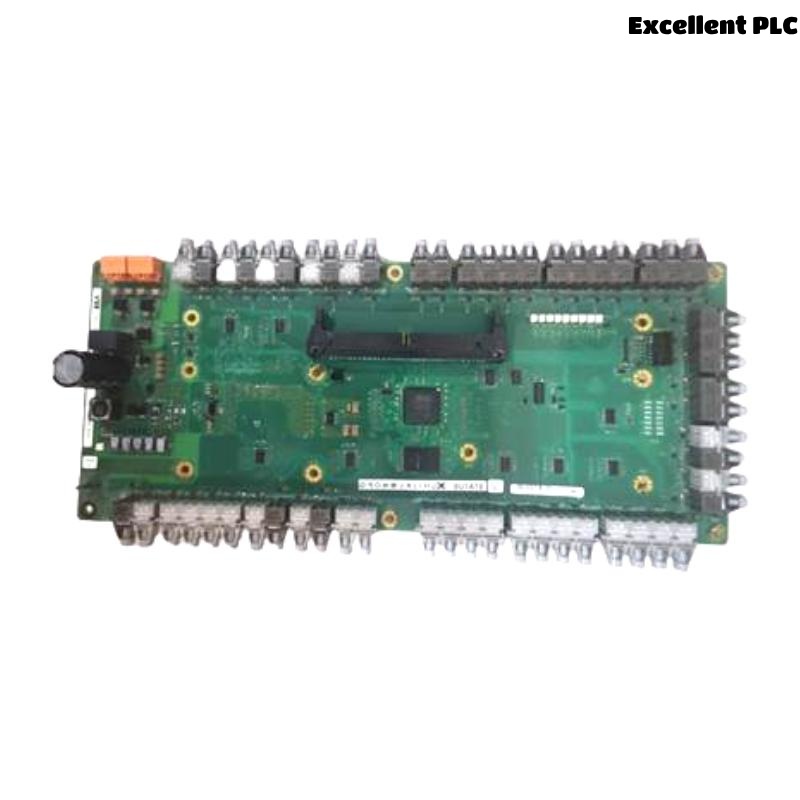

Product Introduction

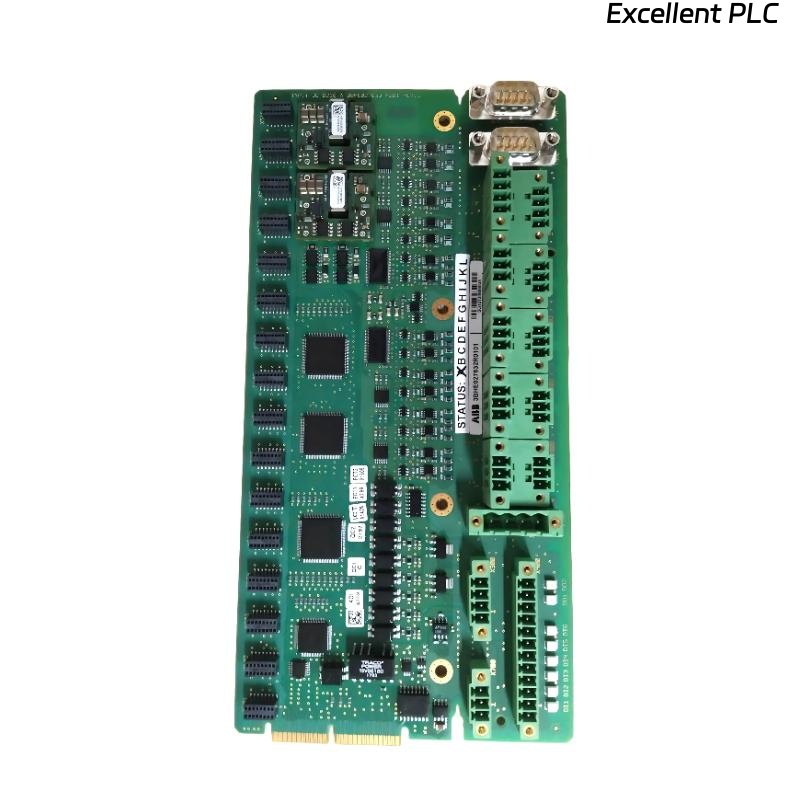

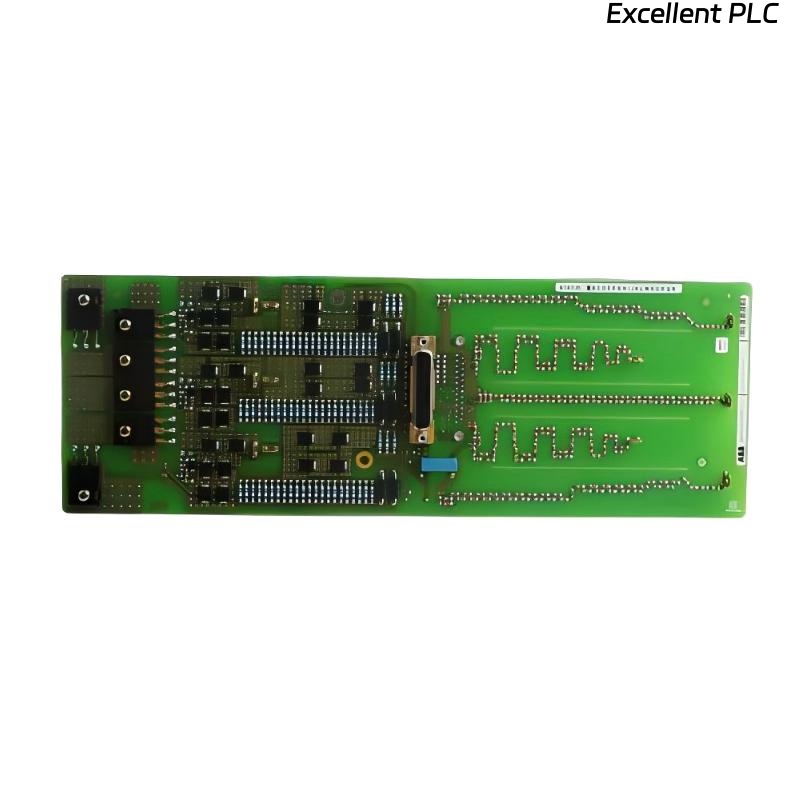

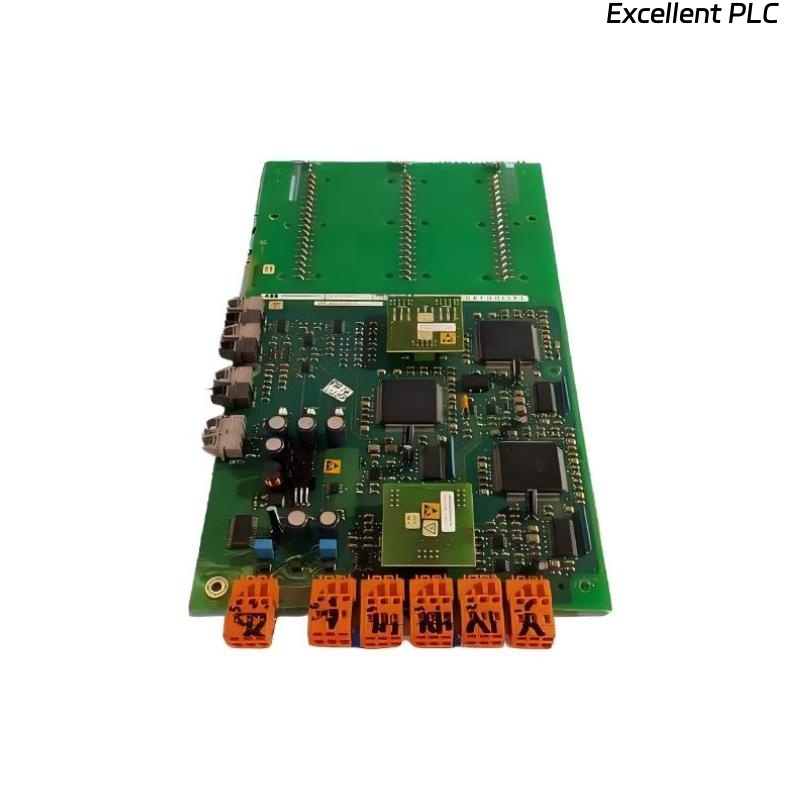

The ABB UA C389 B101 (3BHE059407R0101) is a high-performance inverter module developed as part of ABB’s robust automation and drive solutions for industrial control systems. It is specifically engineered to convert direct current (DC) into variable frequency and amplitude alternating current (AC), delivering efficient and precise control for electric motors in complex industrial environments.

This module belongs to ABB’s highly reliable inverter platform, commonly integrated into drive systems, such as ACS and DCS series drives. The inverter module supports energy-efficient operations and reduces mechanical stress on equipment, resulting in prolonged machine life and reduced operational costs. With rugged construction and high-speed response capability, it is particularly suitable for demanding applications such as rolling mills, cranes, paper machines, and high-inertia systems.

Technical Specifications

| Parameter | Details |

|---|---|

| Manufacturer | ABB |

| Product Code | UA C389 B101 |

| Order Number | 3BHE059407R0101 |

| Product Type | Inverter Module |

| Rated Input Voltage | 600 VDC (nominal) |

| Output Voltage Range | 0 – 600 VAC (variable) |

| Rated Current | 35 A (typical) |

| Cooling Method | Air-cooled (forced ventilation) |

| Control Interface | Fiber optic / Control board integrated |

| Application | Motor drive for industrial AC motors |

| Insulation Class | Class F |

| Protection Rating | IP20 (when enclosed) |

| Mounting Type | Panel or rack-mounted |

| Operating Temperature | -10°C to +55°C |

| Storage Temperature | -25°C to +70°C |

| Relative Humidity | 5% – 95% (non-condensing) |

| Dimensions (W x H x D) | 170 x 230 x 160 mm |

| Weight | 0.1 kg |

Product Applications

The ABB UA C389 B101 inverter module is ideal for a wide variety of motor control and industrial automation applications. Key use cases include:

-

Pulp & Paper Machinery: Ensures precise motor speed and torque control in continuous processing lines.

-

Cranes and Hoists: Allows for smooth acceleration/deceleration, enhancing safety and reliability.

-

Metals Industry: Integrated into rolling mills and furnaces to provide high torque at low speeds.

-

Marine Propulsion Systems: Supports energy-efficient operation of onboard motors.

-

Textile and Printing Machines: Maintains synchronization in high-speed machinery.

Product Advantages

-

High Energy Efficiency: Reduces power consumption with optimal motor speed control.

-

Modular Integration: Easily integrates into larger ABB drive systems with control and power modules.

-

Robust Construction: Engineered for harsh industrial environments with wide operating temperatures.

-

Reduced Downtime: Reliable thermal management and fault-tolerant design minimize unexpected failures.

-

Compact Footprint: Optimized for space-saving installation in control cabinets or equipment housings.

-

Global Support: Backed by ABB’s worldwide service network and technical documentation.

Frequently Asked Questions (FAQ)

1. What does the UA C389 B101 inverter module do?

It converts DC power to variable-frequency AC to control the speed and torque of electric motors.

2. Can this inverter module be used with any ABB drive system?

It is compatible with various ABB drive platforms, especially those using modular inverter architectures such as the DCS or ACS series.

3. What is the cooling method used in this module?

It uses forced air cooling and should be installed with adequate ventilation to prevent overheating.

4. How do I know if the inverter module is operating correctly?

Status LEDs or diagnostic outputs are typically available on the control interface, and ABB offers monitoring tools for more detailed insights.

5. Is this inverter module field-serviceable?

It is recommended that only certified personnel perform maintenance or replacement due to the complexity and high voltages involved.

6. Can it handle regenerative braking?

When paired with the correct braking chopper and resistor module, it supports regenerative braking applications.

7. What protections are built into this module?

It includes overvoltage, undervoltage, overcurrent, and thermal protection features.

8. Does the module include communication interfaces?

It supports fiber optic or integrated interfaces, which depend on the connected control board or system.

9. How long is the typical service life?

With proper cooling and environmental conditions, the service life can exceed 10 years under continuous operation.

10. How is the inverter module connected to control systems?

It typically interfaces via fiber optics or control boards, allowing fast signal transmission and system integration.

Related Models (Same Series or Functionality)

| Model Number | Description | Key Specs |

|---|---|---|

| UA C389 B102 | Inverter module, higher current | 600 VDC, 50 A, 7.2 kg |

| UA C384 B103 | Inverter module with cooling enhancements | 600 VDC, 45 A, water-cooled |

| UA C382 A101 | Compact inverter for small motors | 400 VDC, 20 A, 4.5 kg |

| 3BHE009684R0101 | ABB drive inverter module | 600 VDC, 40 A |

| 3BHB003230R0101 | DCS400 inverter module | 500 VDC, 30 A |

| UA C389 B201 | Inverter with extended temperature range | 600 VDC, 35 A, -25 to 70°C |

Popular ABB Models (Same Brand)

| Model Number | Description | Application |

|---|---|---|

| ACS880-01-07A6-3 | ABB Industrial Drive, Wall-Mounted | Variable-speed AC motor control |

| DCS800-S01-0650-05 | DC drive module, regenerative | Heavy-duty DC motor applications |

| 3BHE009681R0101 | Control board for drive systems | Embedded control logic |

| 07KT98 GJR5253100R3260 | Advant Controller system module | Automation PLC system |

| PM861AK01 3BSE018157R1 | AC 800M controller unit | Process control, redundancy capable |

| CI854AK01 3BSE030220R1 | Communication interface for PROFIBUS | Fieldbus device connectivity |

Excellent PLC

Excellent PLC