| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

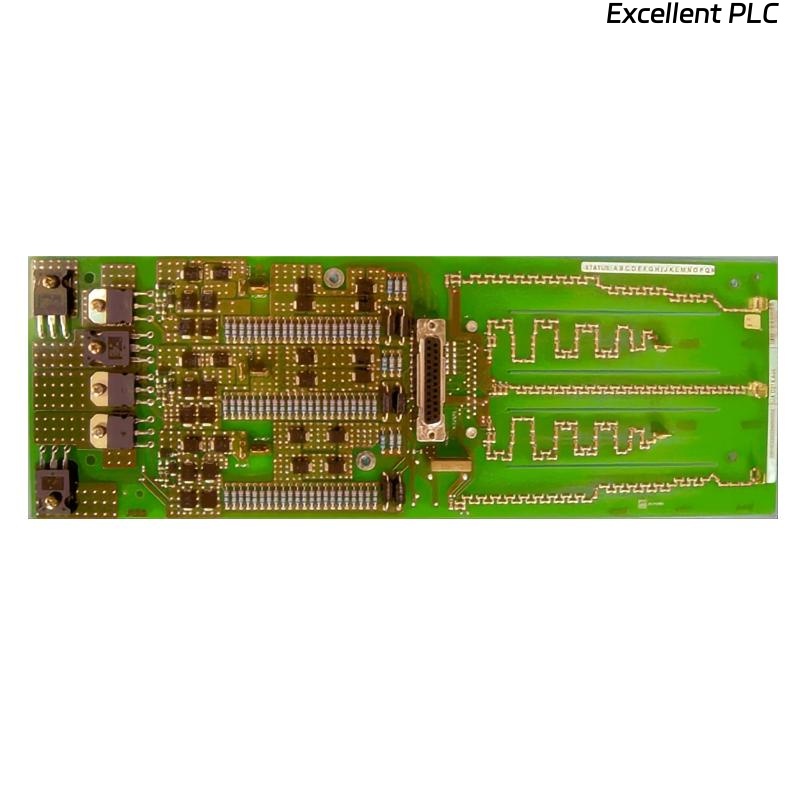

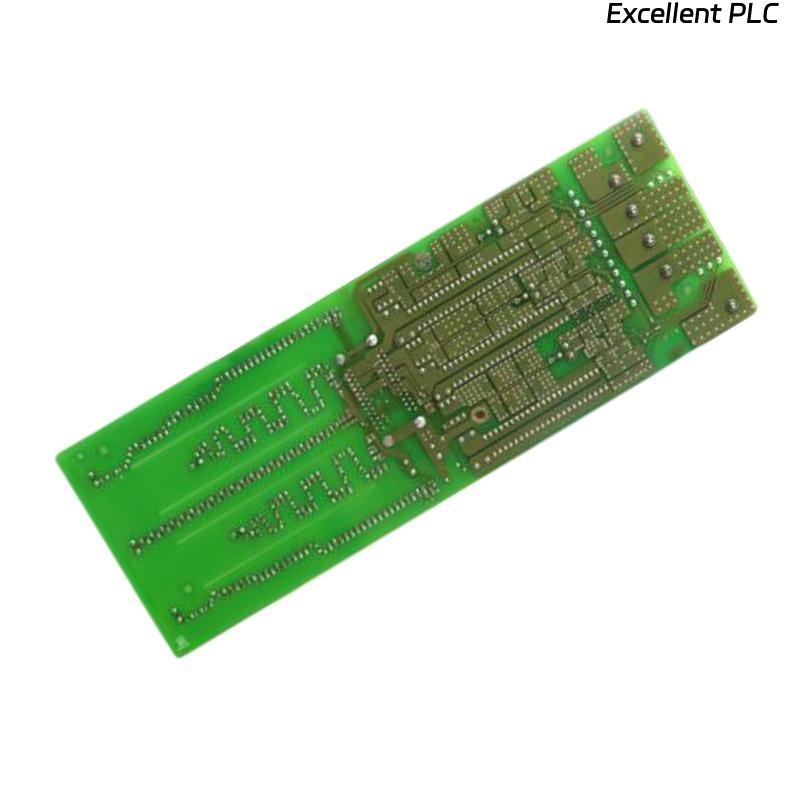

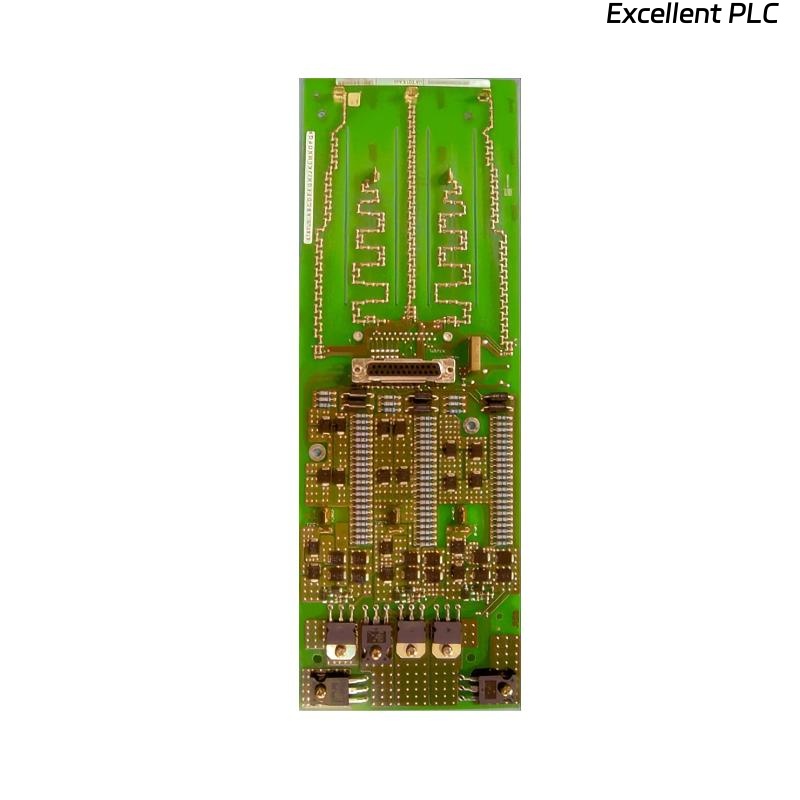

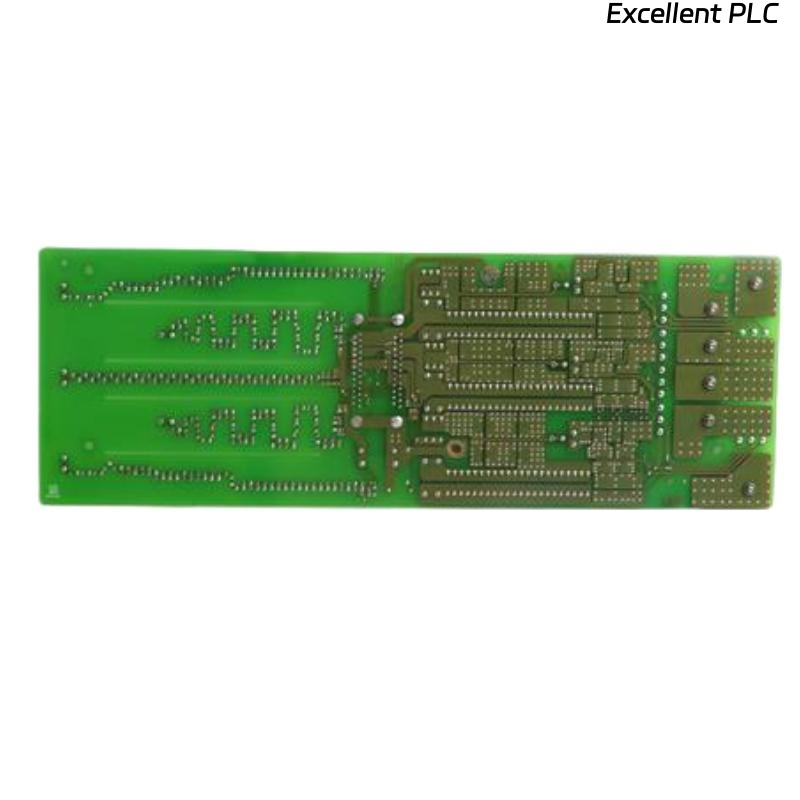

The ABB UA D215 A106 3BHE026284R0106 Converter Signal Input Board is a specialized module designed to interface analog and digital signals with ABB’s control and automation systems. This input board functions as a crucial converter, transforming raw sensor or process signals into precise data that can be processed by control units.

Engineered for accuracy and reliability, the UA D215 A106 is widely used in distributed control systems (DCS) and process automation environments. It supports a variety of input signal types, allowing seamless integration with sensors, transmitters, and other field devices. Its robust construction ensures stable operation under industrial conditions, facilitating consistent performance in demanding applications.

Product Specifications

| Parameter | Details |

|---|---|

| Model Number | UA D215 A106 / 3BHE026284R0106 |

| Functionality | Converter Signal Input Board |

| Input Signal Types | Analog voltage, current, digital inputs |

| Signal Conversion | Analog to digital conversion |

| Power Supply | 24 V DC |

| Communication Interface | Compatible with ABB control systems via backplane bus |

| Operating Temperature | -20 °C to +70 °C |

| Storage Temperature | -40 °C to +85 °C |

| Humidity Range | 5% to 95% (non-condensing) |

| Dimensions (HxWxD) | 340.08 x 117.5 mm |

| Weight | 0.7 kg |

| Mounting | Rack-mounted in control cabinets |

| Certifications | CE, UL, IEC standards compliance |

Product Applications

The UA D215 A106 Converter Signal Input Board is widely applied in industrial automation sectors that require accurate signal conversion and processing, including:

-

Power Plants: Input conversion for turbine control, generator monitoring, and safety interlocks.

-

Oil and Gas: Signal conditioning from pressure, flow, and temperature sensors in upstream and downstream processes.

-

Chemical Plants: Data acquisition from critical process variables for real-time control.

-

Water Treatment: Monitoring and control of water quality and process parameters.

-

Manufacturing Automation: Input integration from various sensors to optimize machine operation.

-

Utilities: Supervisory data acquisition for distributed control systems.

Product Advantages

The ABB UA D215 A106 Signal Input Board delivers distinct advantages critical for reliable process automation:

-

High Accuracy: Provides precise conversion of analog signals to digital format, ensuring data integrity.

-

Multi-Signal Compatibility: Supports a broad range of input types including voltage, current, and digital signals.

-

Robust Design: Built to operate in harsh industrial environments with wide temperature and humidity tolerances.

-

Seamless Integration: Fully compatible with ABB’s distributed control and automation platforms.

-

Compact and Lightweight: Fits easily into control racks, minimizing space requirements.

-

Efficient Signal Processing: Minimizes noise and interference, delivering stable, reliable inputs.

-

Easy Maintenance: Modular design facilitates quick replacement and system upgrades.

-

Wide Operating Range: Maintains performance across extreme environmental conditions.

-

Industry Standard Compliance: Meets international certifications ensuring quality and safety.

-

Strong Diagnostics: Enables quick fault detection and troubleshooting to reduce downtime.

Frequently Asked Questions (FAQ)

-

What types of input signals can the UA D215 A106 board handle?

It accepts analog voltage, current inputs, and digital signals, allowing versatile integration. -

How does the board convert analog signals?

It performs analog-to-digital conversion using high-precision converters embedded on the board. -

Is the input board compatible with all ABB DCS systems?

Yes, it is designed to be fully compatible with ABB distributed control systems and interfaces via the backplane bus. -

What is the operating temperature range for the unit?

The board operates reliably between -20 °C and +70 °C. -

Can the board handle signal noise or interference?

Yes, it includes filtering and noise reduction mechanisms for stable signal acquisition. -

How is the board powered?

It operates on a 24 V DC power supply, consistent with industrial control system standards. -

Is it possible to hot-swap the input board without shutting down the system?

Typically, hot-swapping depends on the specific system configuration and should be confirmed with the system integrator. -

What kind of diagnostic features are built into the board?

It provides signal integrity monitoring and fault indication to assist with preventive maintenance. -

Does the board support digital input signals, and how are they processed?

Yes, digital signals are processed via internal logic and communicated to the control system as discrete inputs. -

Can this input board be used in safety-critical control applications?

While the board supports reliable signal conversion, its use in safety-critical systems requires proper system-level safety design.

Related Models from the Same Series

| Model Number | Description | Key Features |

|---|---|---|

| UA D216 A107 | Signal Output Board | Converts digital signals to analog outputs |

| UA D217 A108 | Analog Input Board | Extended range of analog inputs |

| UA D218 A109 | High-Speed Signal Input Board | Supports faster data acquisition |

| UA D219 A110 | Redundant Signal Input Board | For high availability systems |

| UA D220 A111 | Signal Conditioning Board | Signal filtering and amplification |

| UA D221 A112 | Multi-Signal Interface Board | Supports analog and digital inputs |

Popular ABB Models from the Same Brand

| Model Number | Description | Typical Application |

|---|---|---|

| AC500 PLC | Programmable Logic Controller | General industrial automation |

| DCS800 Drive | Variable Frequency Drive | Motor speed and torque control |

| PCS100 Inverter | Power Converter | Renewable energy systems |

| RTU540 | Remote Terminal Unit | Remote control and monitoring |

| S800 I/O Modules | Distributed I/O Modules | Modular input/output expansion |

| Freelance DCS | Distributed Control System | Process automation integration |

Excellent PLC

Excellent PLC