| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

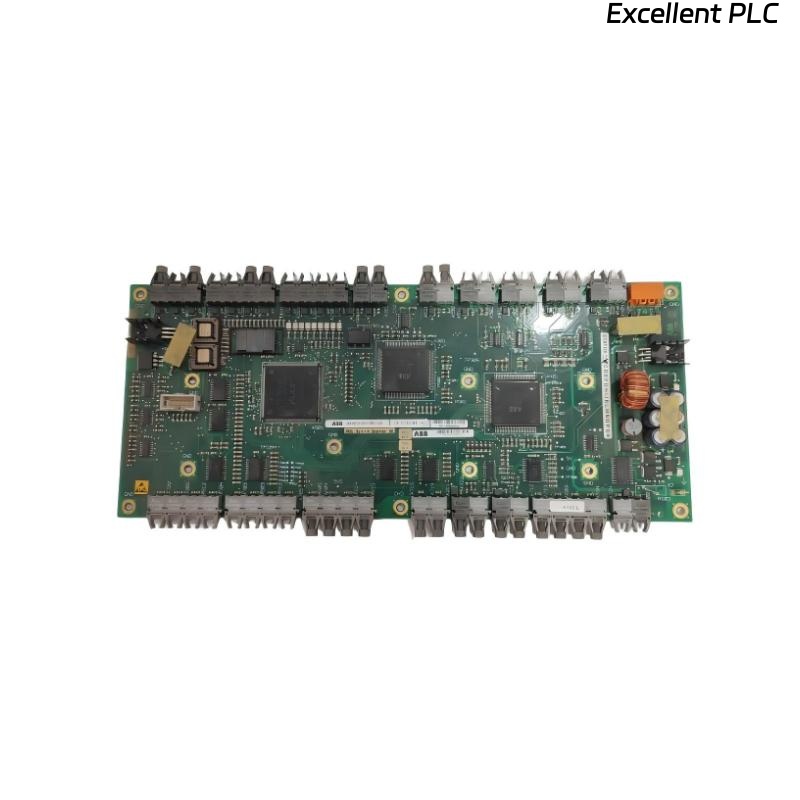

The ABB UF C760 BE145 (3BHE004573R0145) is a high-end CPU controller module designed for next-generation ABB Symphony Plus and Advant distributed control systems (DCS). It represents a major evolution in ABB’s UF C760 series, delivering faster computation, larger memory capacity, and enhanced communication reliability. Engineered for mission-critical applications, the BE145 combines high-speed logic execution, redundant communication interfaces, and rugged industrial performance, making it a trusted choice for continuous process industries requiring 24/7 uptime and operational precision.

Technical Specification Sheet

| Parameter | Specification | Description |

|---|---|---|

| Product Type | CPU Controller Module | Central processor for ABB DCS platforms |

| Model Number | UF C760 BE145 | Advanced high-speed CPU module |

| Part Number | 3BHE004573R0145 | ABB internal product identifier |

| Processor Type | 32-bit RISC industrial CPU | Optimized for real-time process control and logic sequencing |

| Memory Capacity | 512 MB RAM, 256 MB Flash | Supports complex automation programs and data buffering |

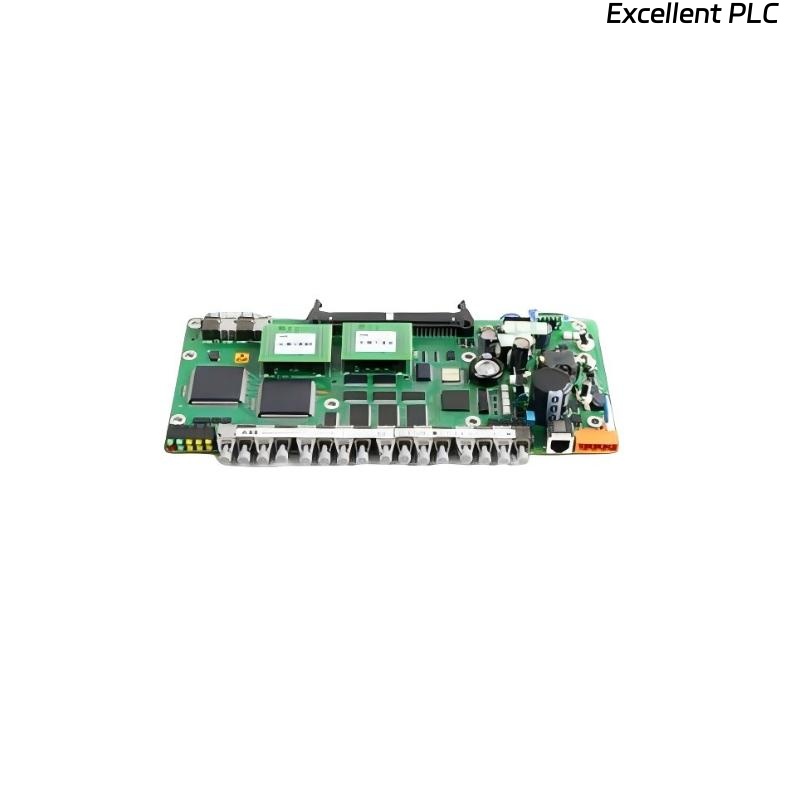

| Communication Interfaces | Dual Ethernet, RS-485, ABB System Bus | Provides redundant and high-speed communication paths |

| Supported Protocols | Modbus TCP/IP, PROFIBUS DP, OPC, ABB Control Network | Ensures interoperability across industrial systems |

| Programming Environment | ABB Control Builder / Symphony Plus Engineering Tool | IEC 61131-3 programming support |

| Power Supply | 24 VDC nominal (19–30 VDC range) | Stable low-voltage operation |

| Power Consumption | 17 W typical | Energy-efficient with high processing capability |

| Operating Temperature | 0°C to +55°C | Designed for continuous industrial operation |

| Storage Temperature | -40°C to +85°C | Supports long-term spare storage conditions |

| Humidity Range | 5% – 95% non-condensing | Suitable for harsh environmental conditions |

| Mounting Type | DIN-rail or rack-mounted | Flexible installation within control cabinets |

| Diagnostics | Built-in self-test with multi-LED status indicators | Simplifies field troubleshooting and health monitoring |

| EMC Compliance | IEC/EN 61000-6-2, IEC/EN 61000-6-4 | Meets industrial EMI and EMC standards |

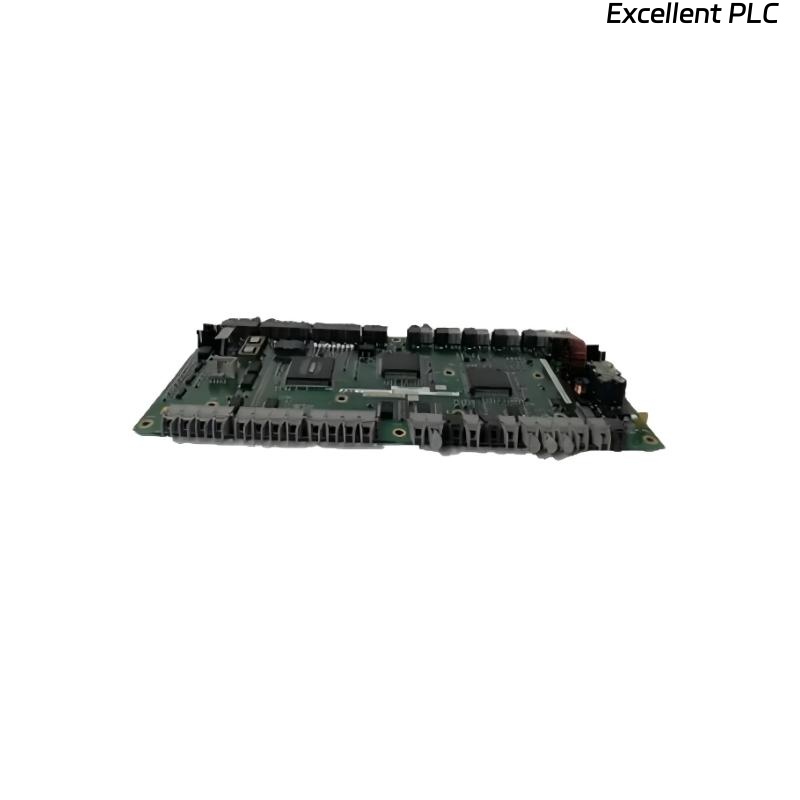

| Dimensions (H × W × D) | 128 mm × 35 mm × 150 mm (5.04″ × 1.38″ × 5.91″) | Compact modular structure for space efficiency |

| Weight | 0.50 kg (1.10 lb) | Rugged aluminum housing for durability |

Operational Applications

-

Power Generation Plants: Primary logic control for turbines, generators, and boiler systems.

-

Oil & Gas Refineries: Supervisory control for compressors, pumps, and safety loops.

-

Chemical & Petrochemical: High-speed batch automation and continuous process regulation.

-

Water and Wastewater Treatment: Flow balancing, pump control, and process monitoring.

-

Pharmaceutical Manufacturing: GMP-compliant automation with high control accuracy.

-

Metallurgy and Mining: Heavy process synchronization and load regulation.

-

Marine and Energy Systems: Real-time distributed control for hybrid energy grids.

Competitive Advantages

-

Superior Processing Power: Doubled performance compared to BE142, ideal for advanced DCS tasks.

-

Extended Memory Resources: Supports complex applications with large data handling capacity.

-

Advanced Communication Redundancy: Dual Ethernet architecture ensures zero communication downtime.

-

Fully Compatible Integration: Works seamlessly with ABB Symphony Plus and Advant systems.

-

Resilient Industrial Design: Resistant to vibration, temperature, and EMI disturbances.

-

Rapid Diagnostics: LED indicators and onboard tests reduce maintenance complexity.

-

Remote Firmware Updates: Supports Ethernet-based updates for long-term maintainability.

-

High System Uptime: Engineered for 24/7 critical process availability.

-

Flexible Mounting: Rack and DIN-rail compatibility simplify system retrofits.

-

Lifecycle Longevity: Supported by ABB’s global service and spare part continuity program.

Excellent PLC

Excellent PLC